Energy-saving scouring and bleaching method

A technology for refining and bleaching and formulation, applied in the field of environmental protection refining and bleaching, can solve the problems of high energy consumption and long time, and achieve the effects of reduced strength loss, convenient operation and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Energy-saving technology developed and application effect:

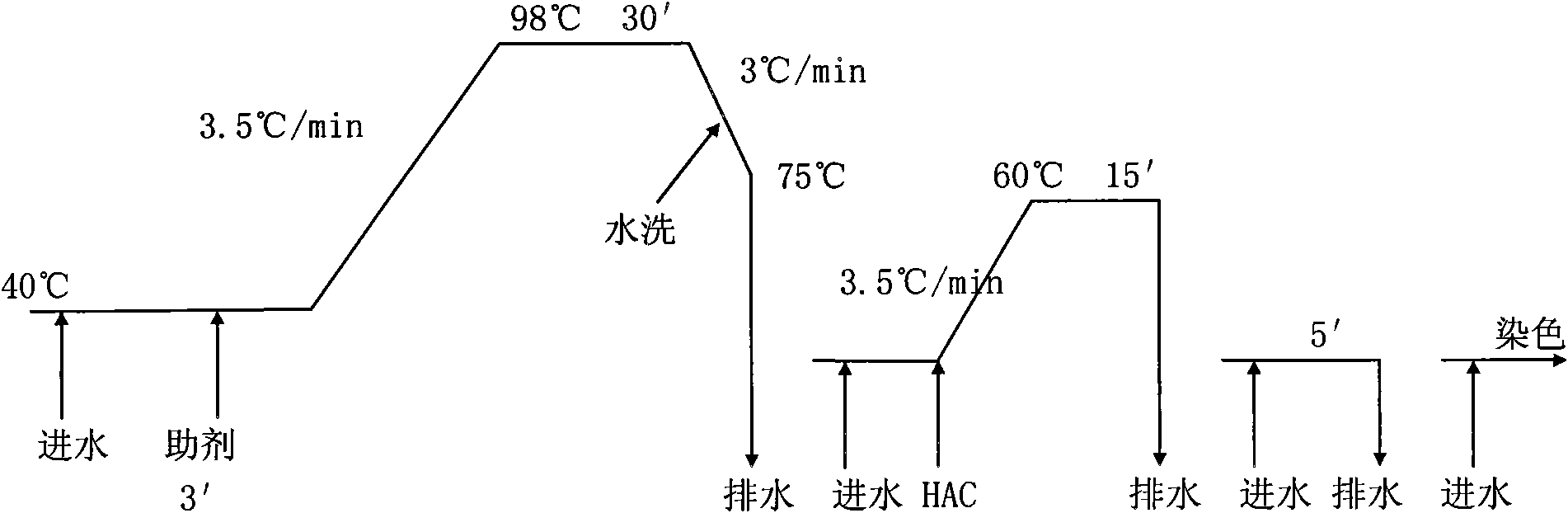

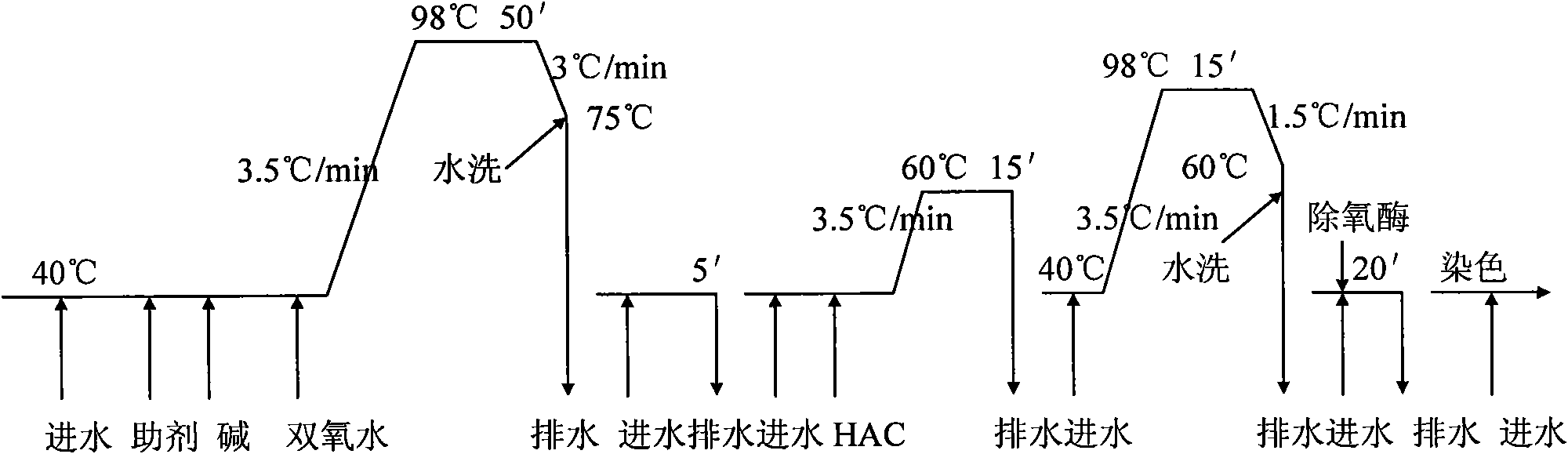

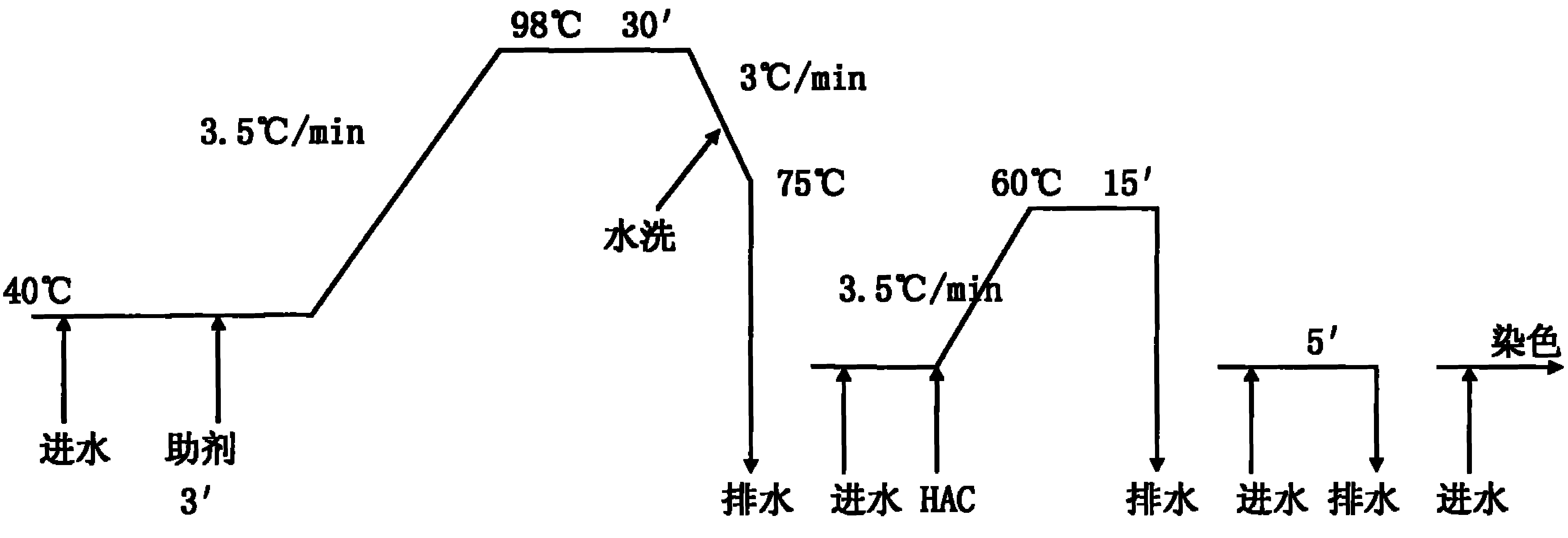

[0033] One, such as figure 1 The steps shown are implemented, compared with the conventional process (the implementation steps are as figure 2 As shown), the process prescription is described in the following table:

[0034] Table I

[0035] Craft prescription

Energy-saving scouring and bleaching process

Conventional process

--

5g /

Caustic soda

--

1.6g / l

--

0.3g / l

--

1g / l

5g / l

--

Bath ratio

1:10

1:10

Temperature / time

One-dose solid additives function 98℃ / 30′

Conventional process 98℃ / 50′

Deoxygenase

--

0.1g / l

[0036] Craft prescription

Energy-saving scouring and bleaching process

Conventional process

HAc

0.8g / l

0.8g / l

Water usage

4 channels

7 channels

[0037] 2. Application effect:

[0038] Table II

[0039]

[0040] Remarks:

[0041] ①Tradition: It is a traditional oxygen ble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com