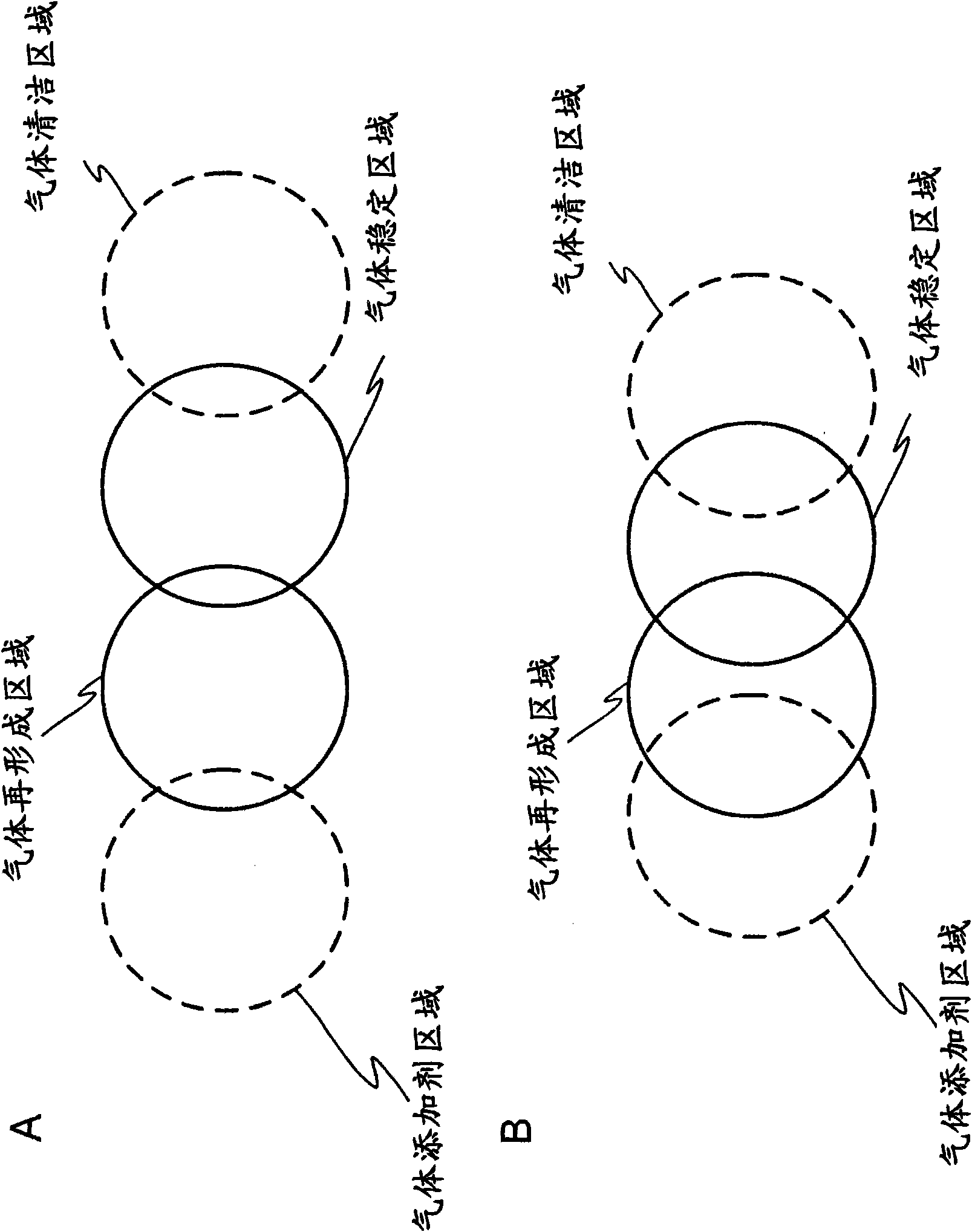

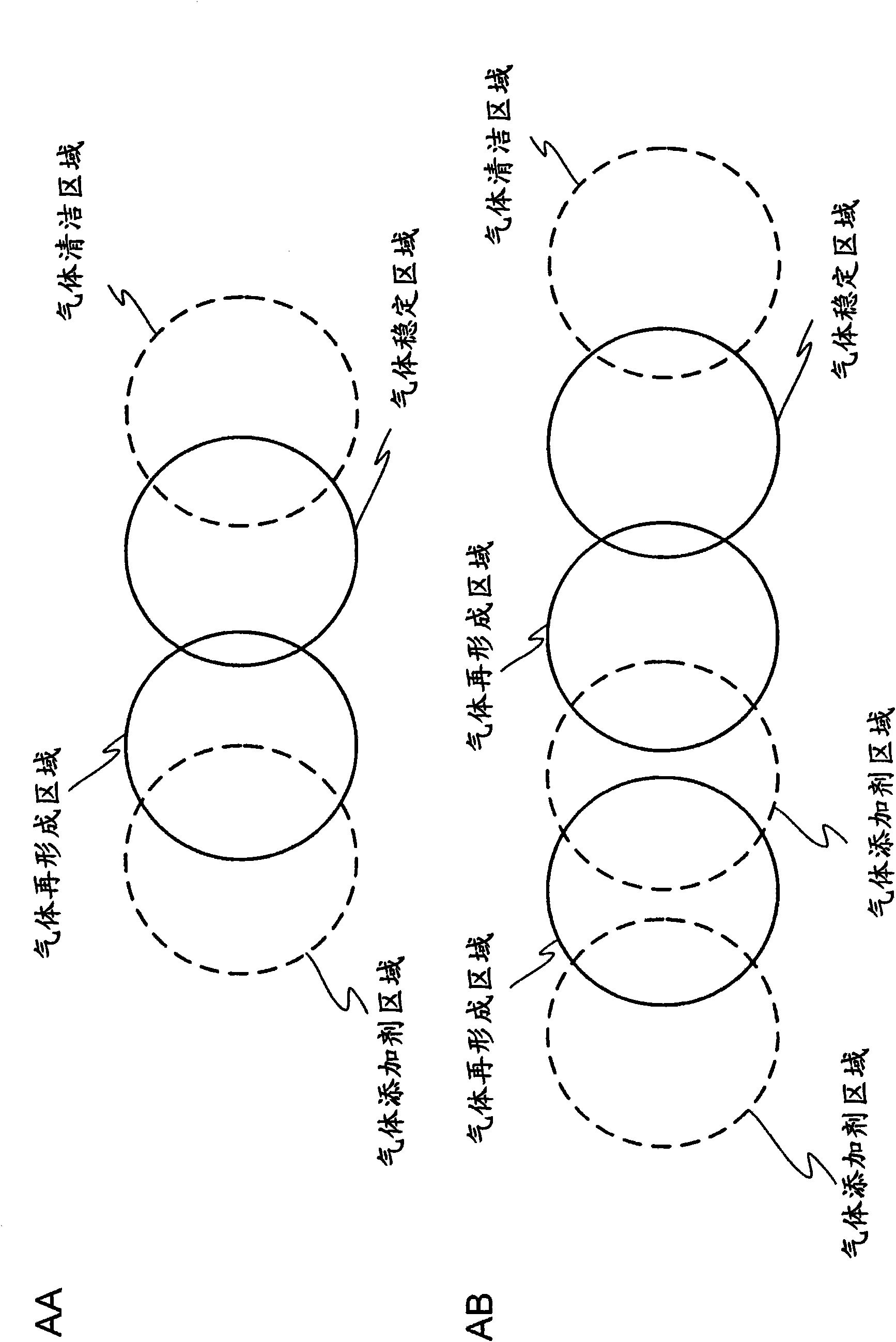

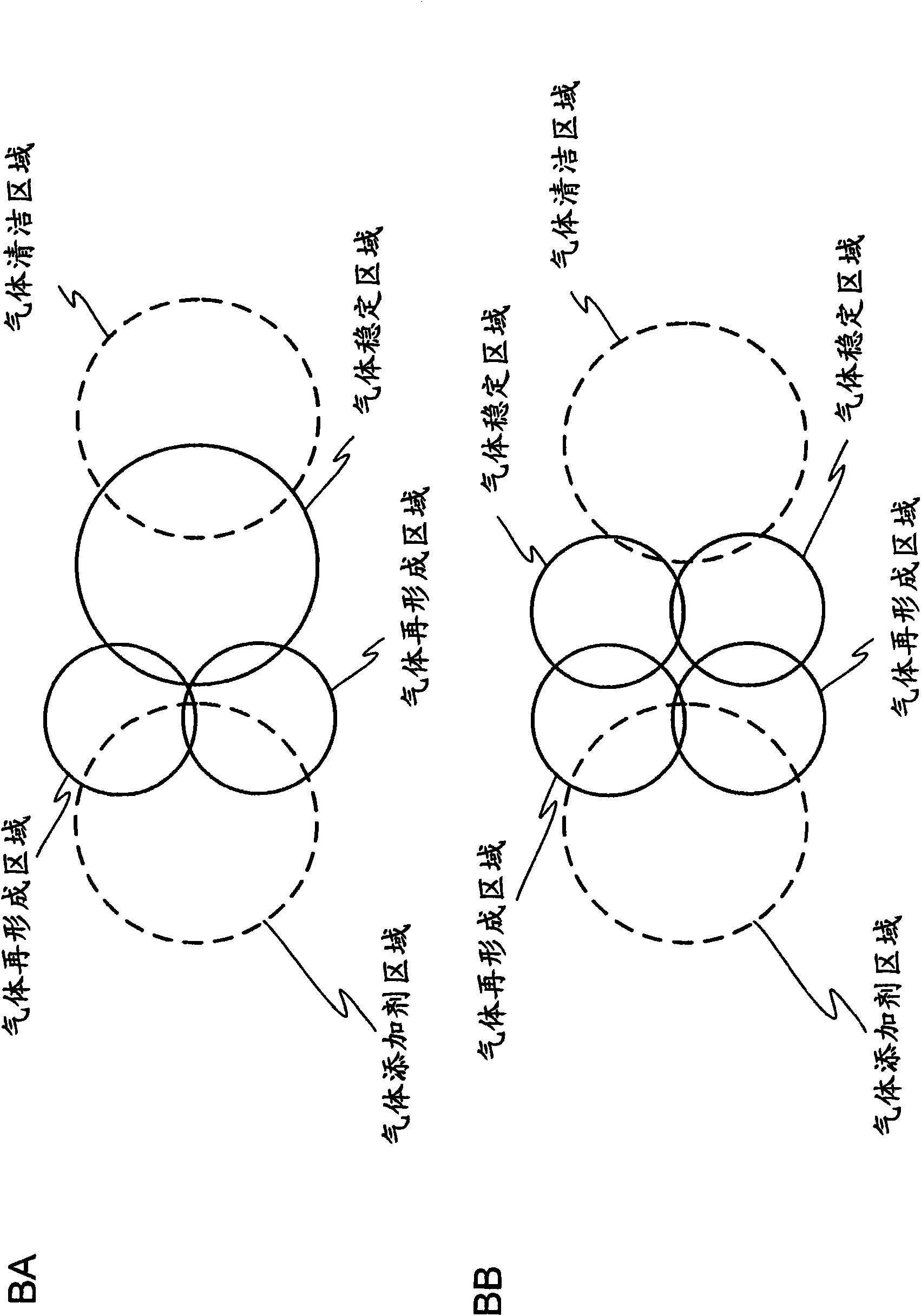

A gas reformulation system comprising means to optimize the effectiveness of gas conversion

A gas and control system technology, which is applied in the direction of gas generation device, catalytic treatment of combustible gas and gas fuel, etc., can solve the problem of not optimizing the overall efficiency of high-energy mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] Unless defined otherwise, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the art.

[0076] As used herein, the word "about" refers to a variation of ±10% from the nominal value. It should be understood that such variations are always included in any given value provided herein, whether or not it is specifically indicated.

[0077] The term "reactive species" refers to the reactive species formed throughout the reformation process. Non-limiting examples include free electrons generated by energy sources such as plasmas or elementary or dissociated intermediates (inductive intermediates) in exhaust gases (e.g., syngas ), transfer energy to other molecules and / or dissociated intermediates / segments of the preformed gas (“preformed molecules”), enabling them to reformulate to a chemical composition with design specifications. Those skilled in the art will appreciate that as the energy transfer process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com