A textile artificial blood vessel with improved radial compliance

A technology for artificial blood vessels and blood vessels, applied in the field of textile artificial blood vessels, can solve the problem of not considering the compatibility of the radial compliance of the host blood vessels, and achieve the effect of maintaining dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

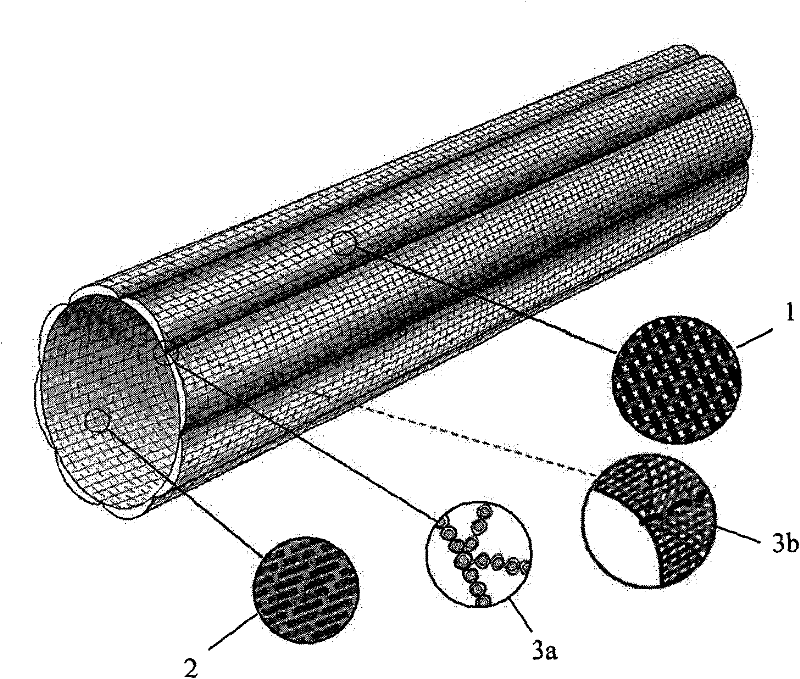

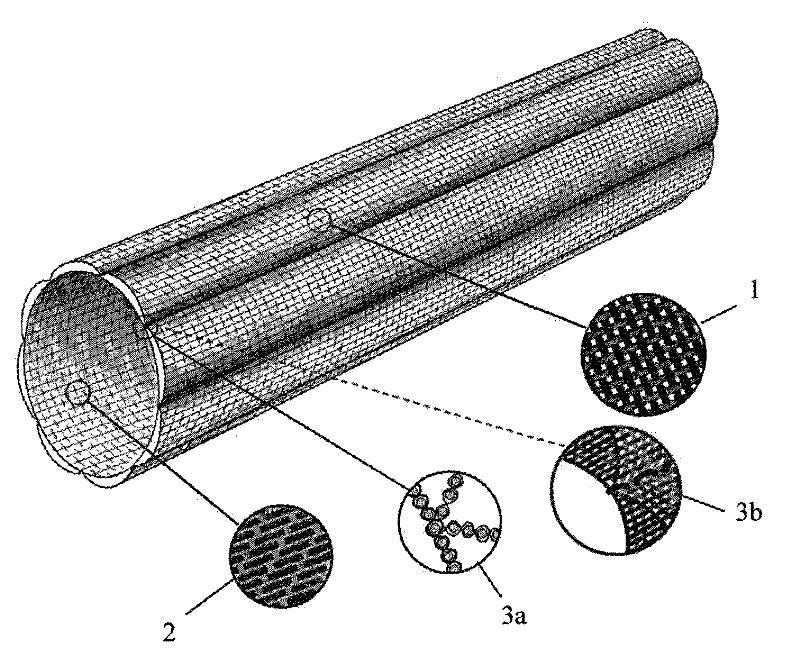

[0031]An artificial blood vessel with a double-layer woven structure, consisting of an outer fabric tube 1 and an inner fabric tube 2, the inner fabric tube 2 is connected in the direction of the generatrix of the outer wall, and the outer fabric tube 1 is coaxially nested in the The connection point on the inner layer fabric tube 2 and through the direction of the outer wall of the inner layer fabric tube 2 is connected with the inner layer fabric tube 2 by the binding yarn of the fabric tissue 3a or the sewing connection 3b; through the outer layer fabric tube 1 and the inner layer fabric The connection of the tubes 2 makes a non-continuous annular space exist in the inner and outer fabrics, and makes the outer fabric tube 1 cover the outer surface of the inner fabric tube 2 in a buckling shape.

[0032] Yarn: 25d PET (polyester) filament is used for the warp yarn of the inner fabric tube, and 20d PTT (1,3-trimethylene terephthalate) filament is used for the weft yarn; 25d is...

Embodiment 2

[0040] Yarn: 45d PET (polyester) filament is used for the warp yarn of the inner fabric tube, and 50d PTT (1,3-trimethylene terephthalate) filament is used for the weft yarn; 45d PET is used for the warp yarn of the outer fabric tube Filament and weft are made of 45d PET filament.

[0041] Fabric weave: Plain weave is used for the inner fabric, and plain weave is used for the outer fabric.

[0042] Fabric density: The warp density of the inner fabric is 805 threads / 10cm, and the weft density is 630 threads / 10cm. The warp density of the outer fabric is 805 threads / 10cm, and the weft density is 605 threads / 10cm.

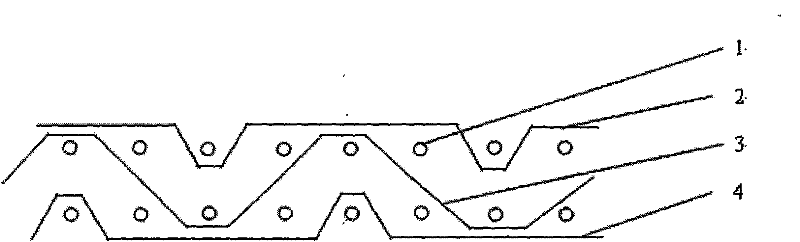

[0043] The inner layer fabric tube and the outer layer fabric tube are connected by the binding yarn of the fabric structure 3a, see the interweaving rule figure 2 .

[0044] Tube Fabric Diameter: The diameter of the inner fabric tube is 5.4mm, and the diameter of the outer fabric tube is 6.8mm.

[0045] Circumferential tensile modulus of the fabric: the circumfer...

Embodiment 3

[0048] Yarn: 75d PET (polyester) filament is used for the warp yarn of the inner fabric tube, and 70d PTT (1,3-trimethylene terephthalate) filament is used for the weft yarn; 75d warp yarn is used for the outer fabric tube The PET filament, the weft yarn is made of 75d PET filament.

[0049] Fabric weave: Plain weave is used for the inner fabric, and 2 / 1 twill weave is used for the outer fabric.

[0050] Fabric density: the warp density of the inner fabric is 605 threads / 10cm, and the weft density is 580 threads / 10cm; the warp density of the outer fabric is 605 threads / 10cm, and the weft density is 500 threads / 10cm.

[0051] The inner layer fabric tube and the outer layer tube fabric are connected 3b by sewing.

[0052] Tube Fabric Diameter: The diameter of the inner fabric tube is 6.5mm, and the diameter of the outer fabric tube is 7.6mm.

[0053] Circumferential tensile modulus of the fabric: the circumferential tensile modulus of the inner fabric tube is 260MPa, and the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com