Numerical control laser cutting machine

A digitally controlled laser and cutting machine technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as direct blanking, high manufacturing cost, and huge structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

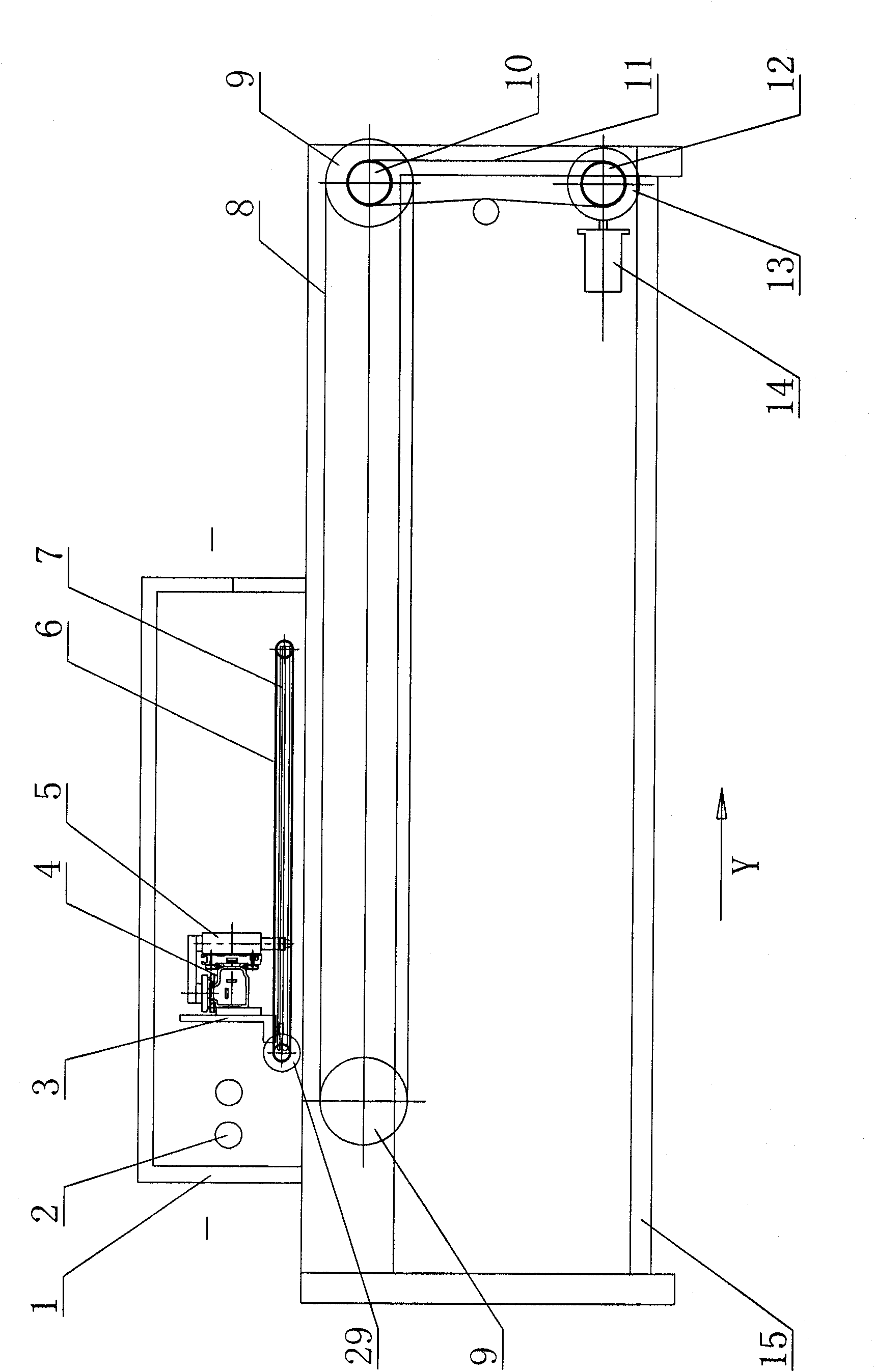

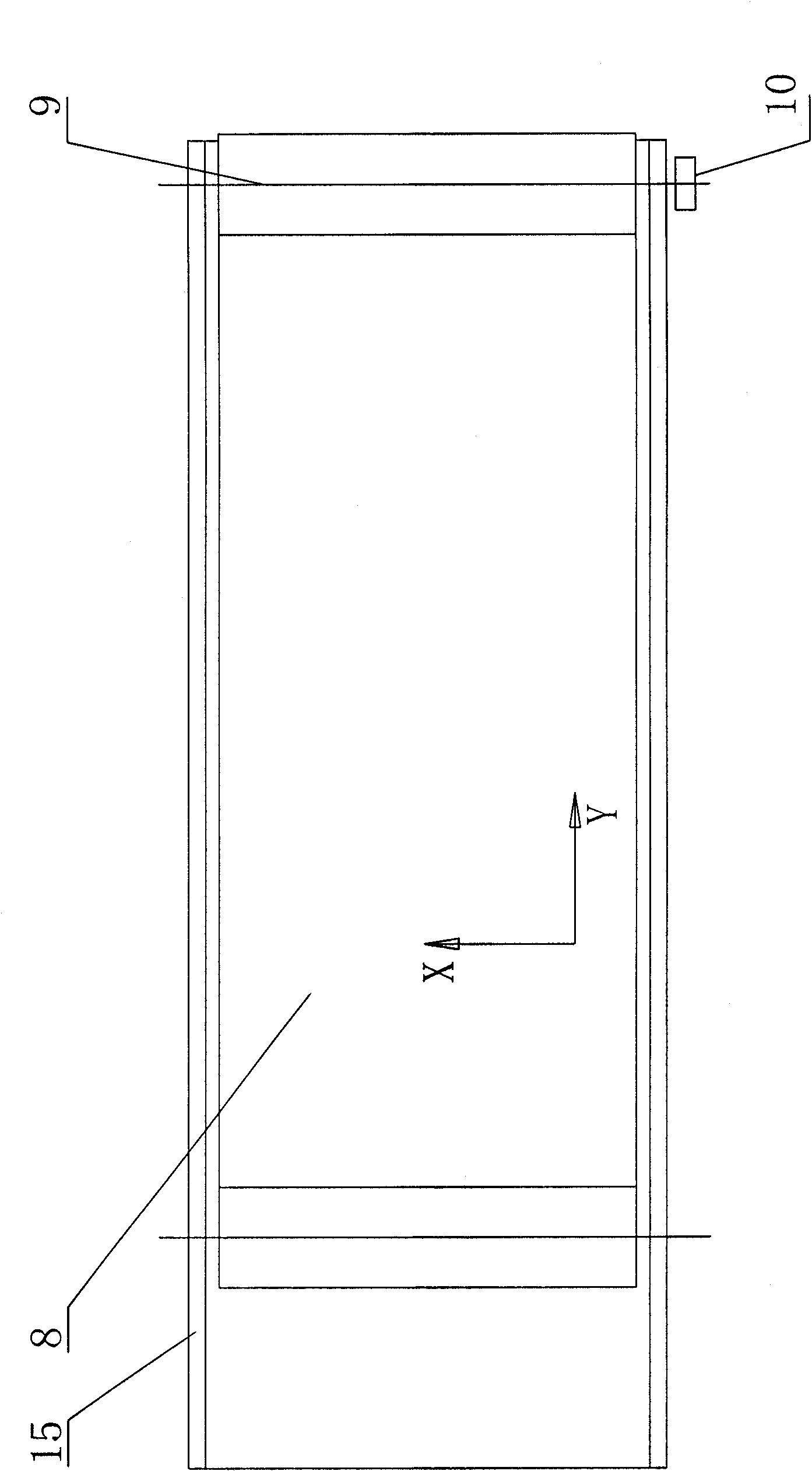

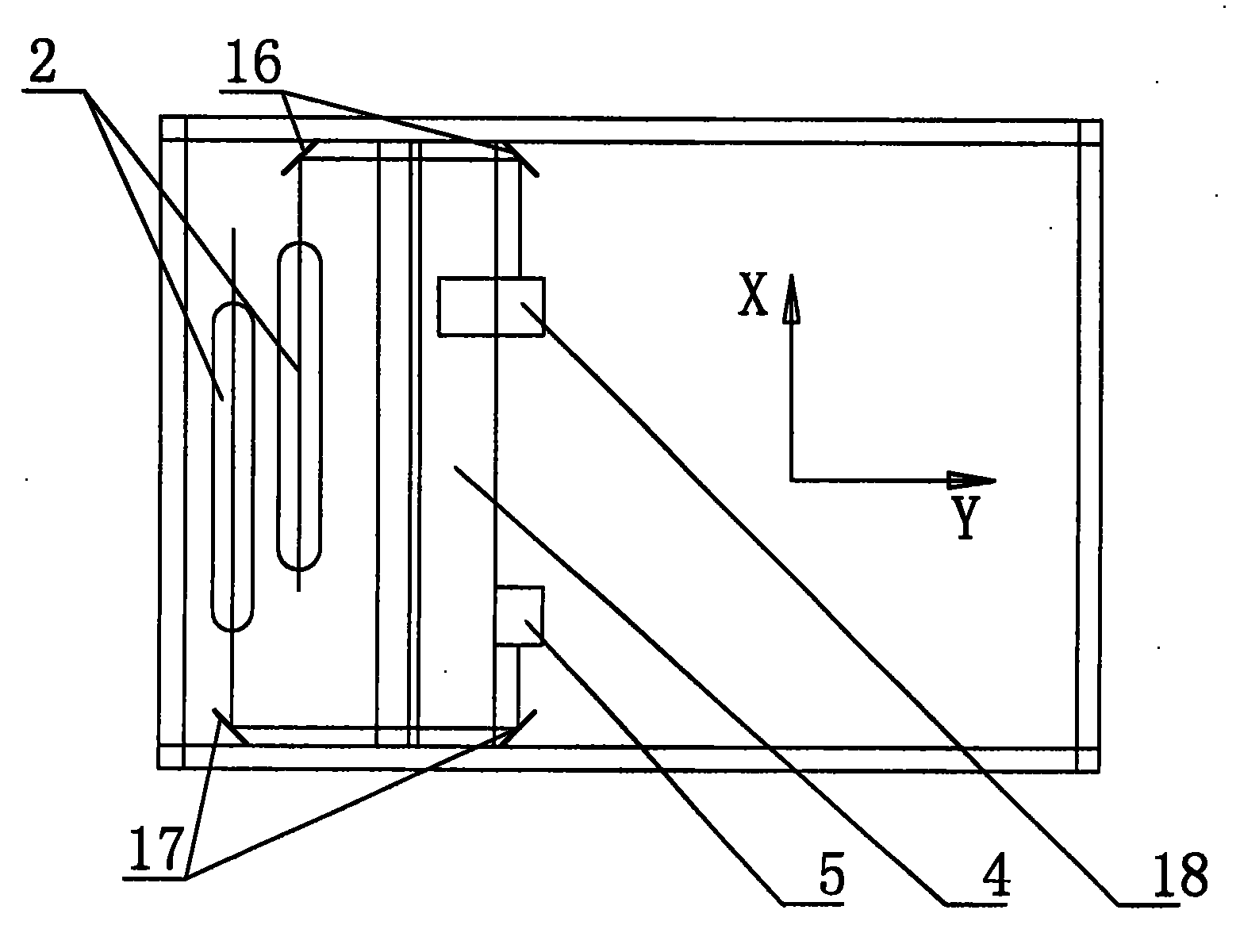

[0016] Such as Figure 1-5 As shown, it is a laser cutting machine, its structure mainly includes a fuselage 15, two laser generators 2 are arranged on the fuselage 15, and two sets of mirrors 16, 17 are arranged on the fuselage corresponding to the laser generator 2 Two groups of reflectors 16, 17 are located on both sides of the fuselage 15, corresponding to the two laser heads 5, 18 that can move along the X-axis and Y-axis, and the fuselage is horizontally provided with two rubber rollers whose axes are parallel 9. A conveyor belt 8 is wound on the rubber roller 9, and the conveyor belt 8 is composed of steel wires connected to each other to form a mesh. The end of any rubber roller is provided with a sprocket 10, and the sprocket 10 is connected to the feeding step by the chain 11. The sprocket 12 at the output shaft end of the reducer 13 of the motor 14 shaft belt is connected in transmission.

[0017] In order to make the laser head 5,18 move along the Y axis on the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com