Production line for complete machine finishing and assembly of aircraft

A production line and complete machine technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problem that the production equipment of precision machine tools has not been greatly improved, and achieve the effect of easy programming and operation, and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

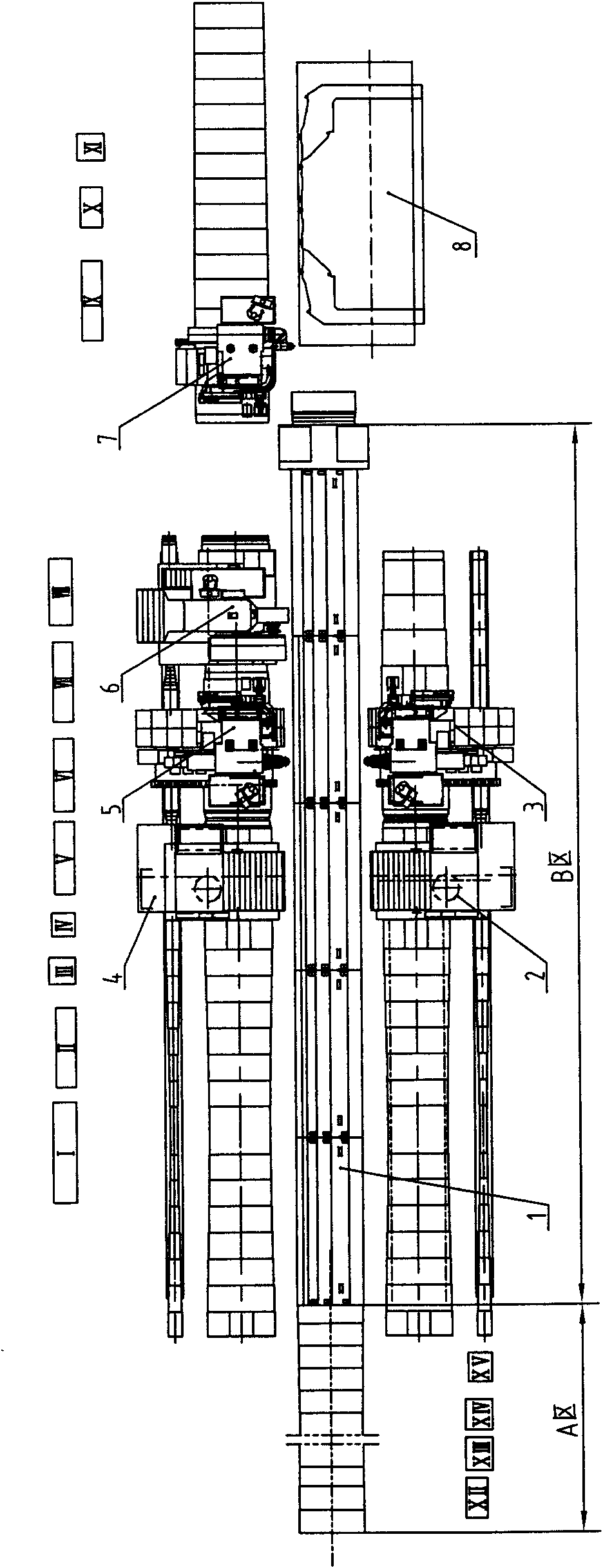

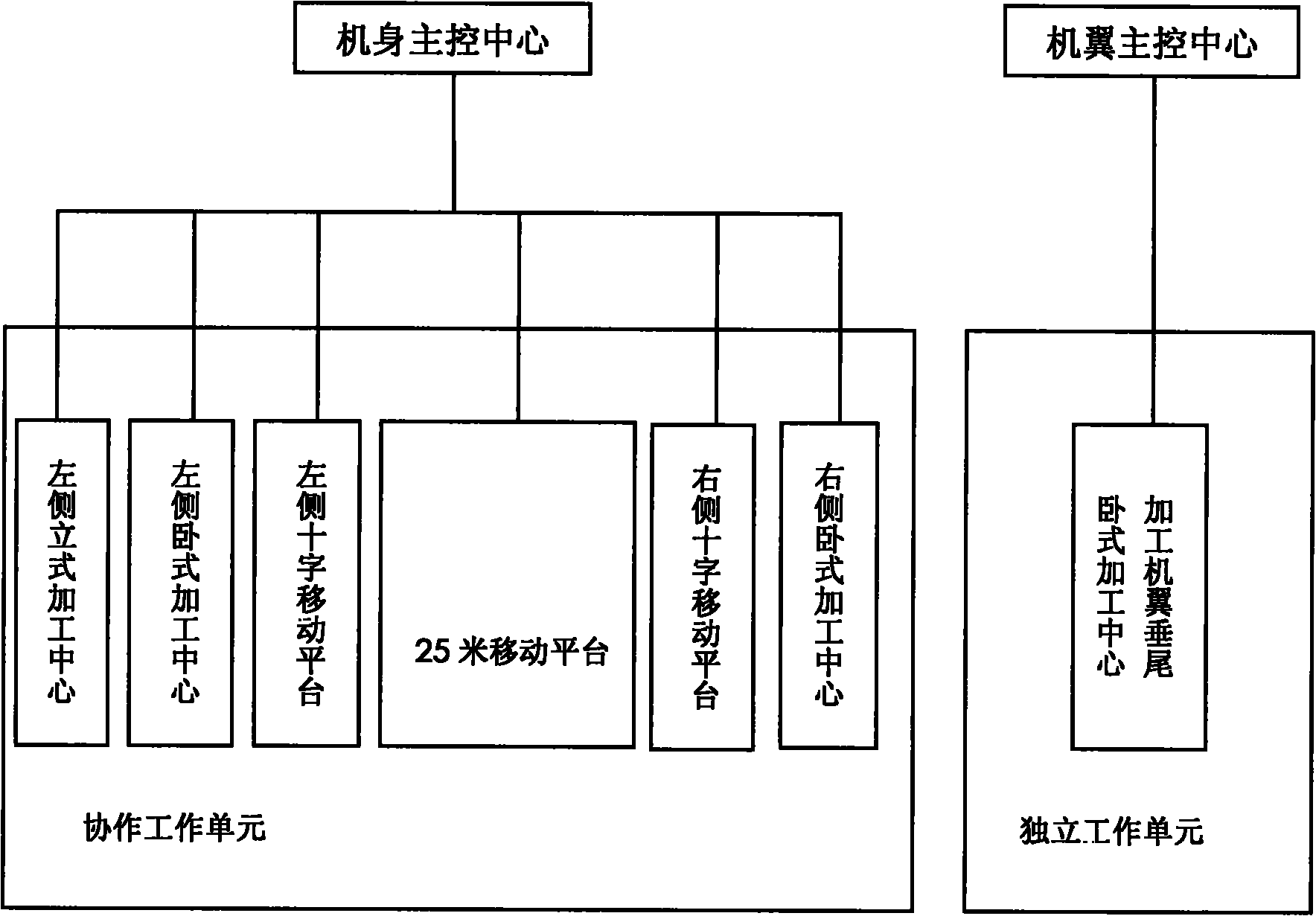

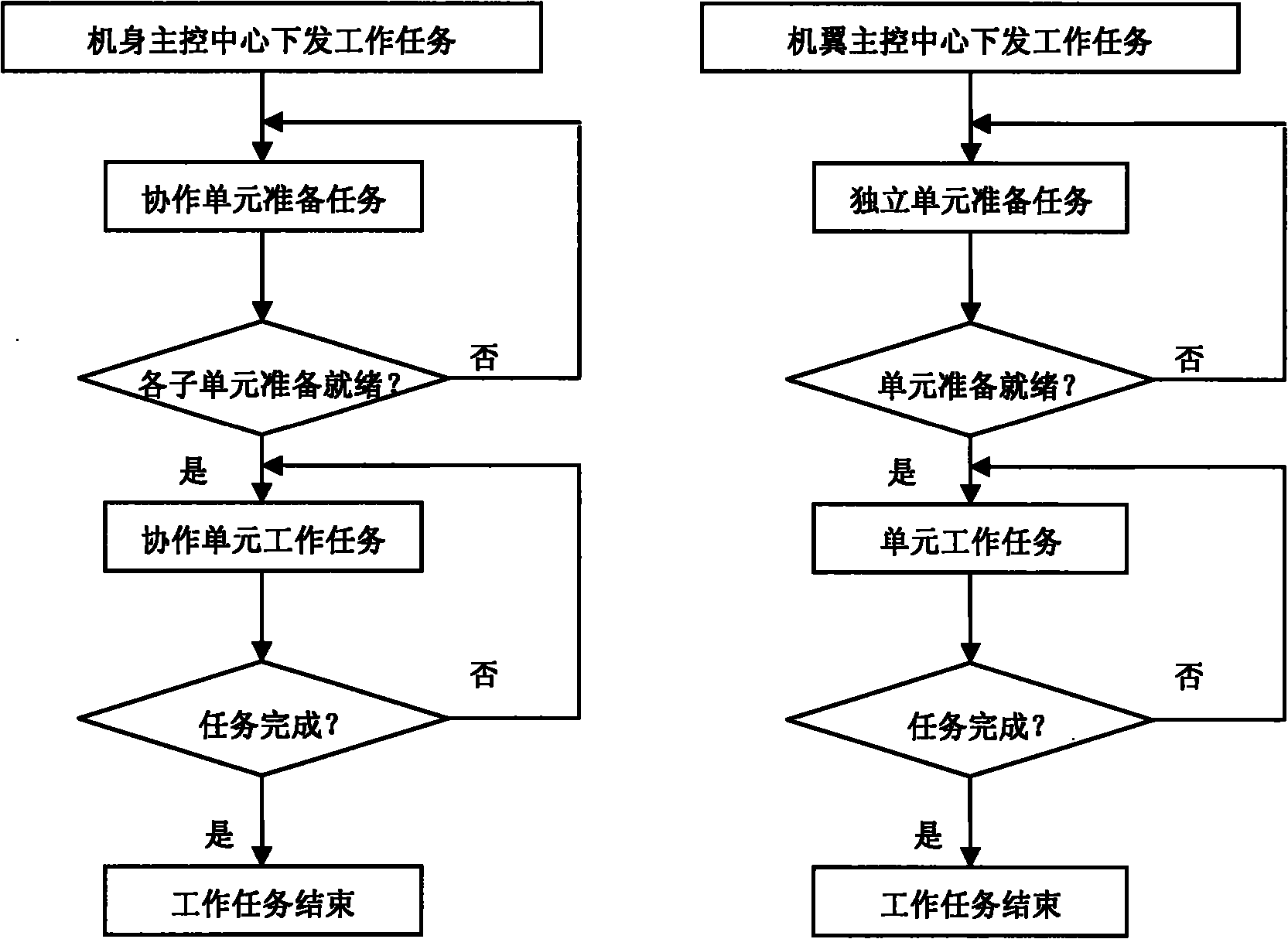

[0014] The production line used for the finishing and assembly of aircraft complete machines, including horizontal machining centers 3 and 5, vertical machining centers 6 and mobile platforms 1, 2 and 4, is divided into two work areas, see figure 1 , which is characterized in that the same mobile platform track is set in the two working areas, and six small moving platforms with clamps will be installed on the 25-meter mobile platform 1 driven by rack and pinion. Assembly (the small moving platform with fixtures will not be described in detail here), the stroke of the 25-meter mobile platform 1 is 17 meters, and the direction of movement is parallel to the aircraft, which can move the assembled aircraft from the assembly work area A to the processing work area and robot operation area B, in the processing work area and robot operation area B, symmetrically arranged along the two sides of the 25-meter mobile platform for the installation of robots, accompanying lifting operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com