Vibration-adsorption structure of carving knife of digital wide-width electronic carving machine

A technology of electronic engraving and vibration damping structure, applied in vibration suppression adjustment, non-rotation vibration suppression, printing and other directions, can solve the problem of difficult damping coefficient of shock absorbers, and achieve the effect of stable engraving process, high quality and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the drawings and implementation process.

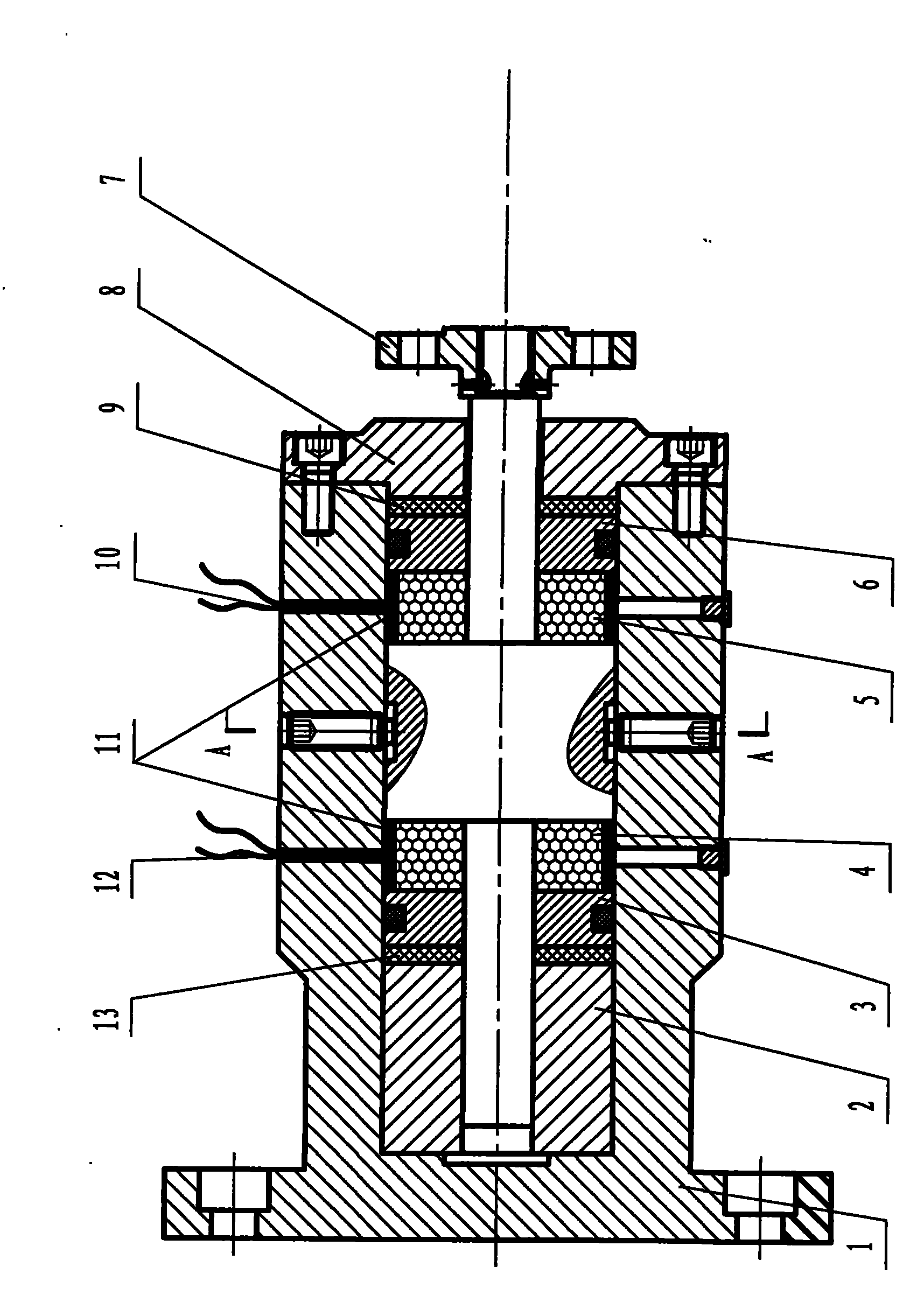

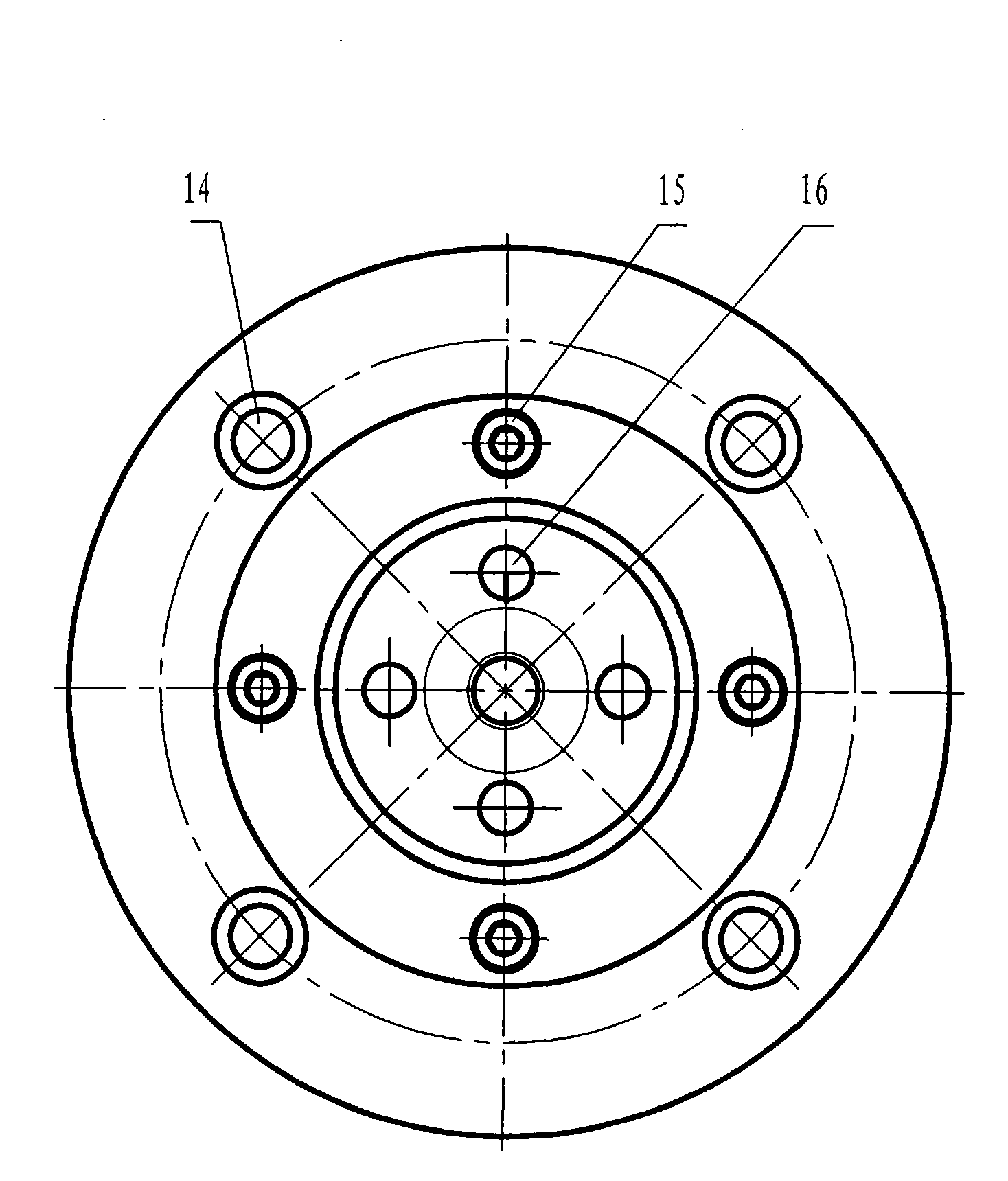

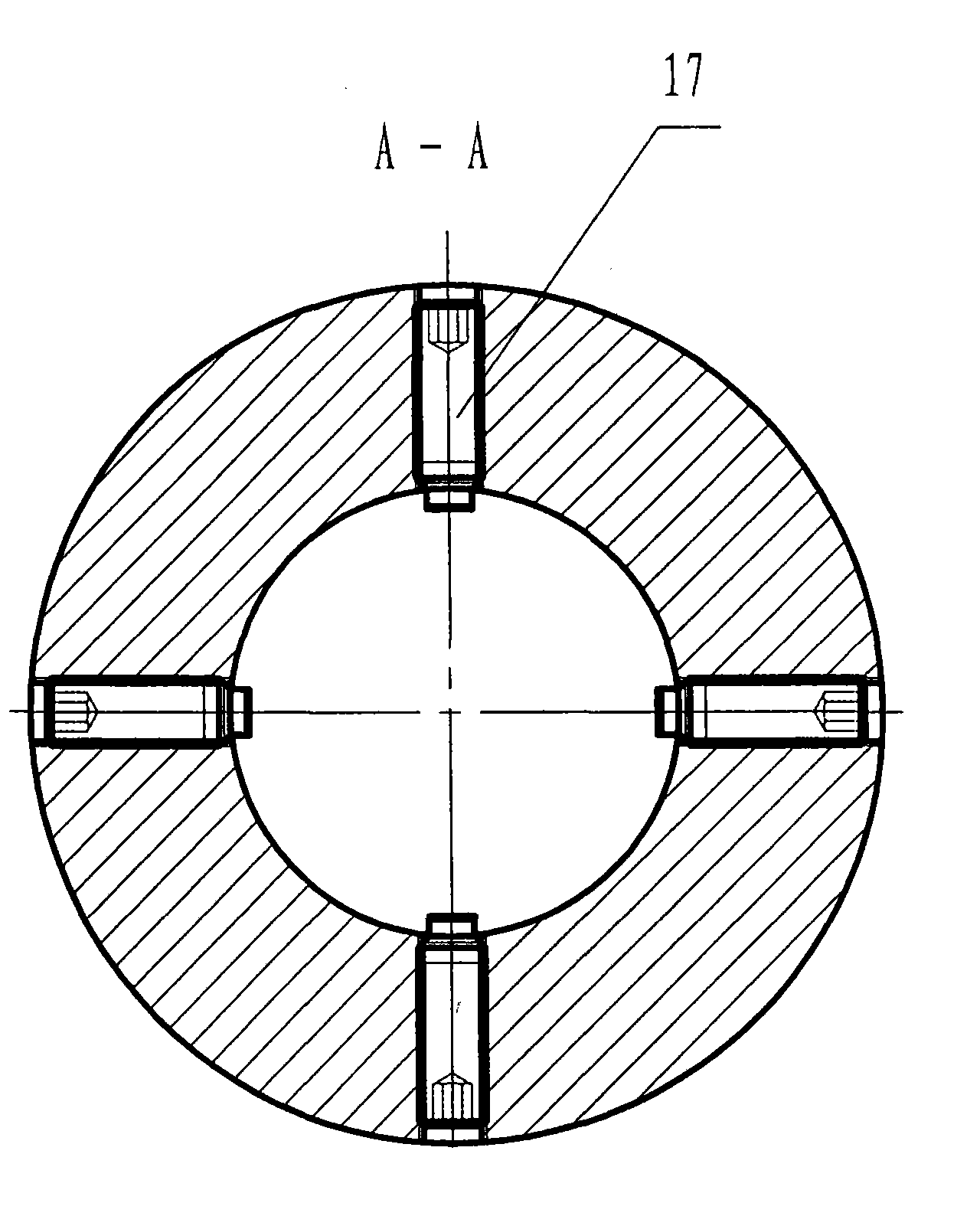

[0015] refer to figure 1 , figure 2 , image 3 , Figure 4 In the present invention, a cylindrical cantilever 18 with small ends and a large center is installed in the center hole of the support sleeve 1, and the large cylindrical cantilever 18 in the middle is sequentially equipped with the first exciting coil 4 and the first small cylinder on the inner side of the support sleeve 1. The spacer 3, the first buffer pad 13, the magnetic isolation sleeve 2, the first excitation coil 4 and the support sleeve 1 are filled with magnetorheological fluid 11; The second excitation coil 5, the second spacer ring 6 and the second buffer pad 9 are installed, and the magneto-rheological fluid 11 is filled between the second excitation coil 5 and the support sleeve 1; the opening of the support sleeve 1 passes through the end cover fixing hole 15 End cap 8 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com