Emulsified starch with high degree of substitution and preparation method thereof

A technology of emulsified starch and high degree of substitution, which is applied in the direction of fermentation, etc., can solve the problems of low reaction efficiency, insufficient surface active physical and chemical properties of products, and low degree of substitution of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

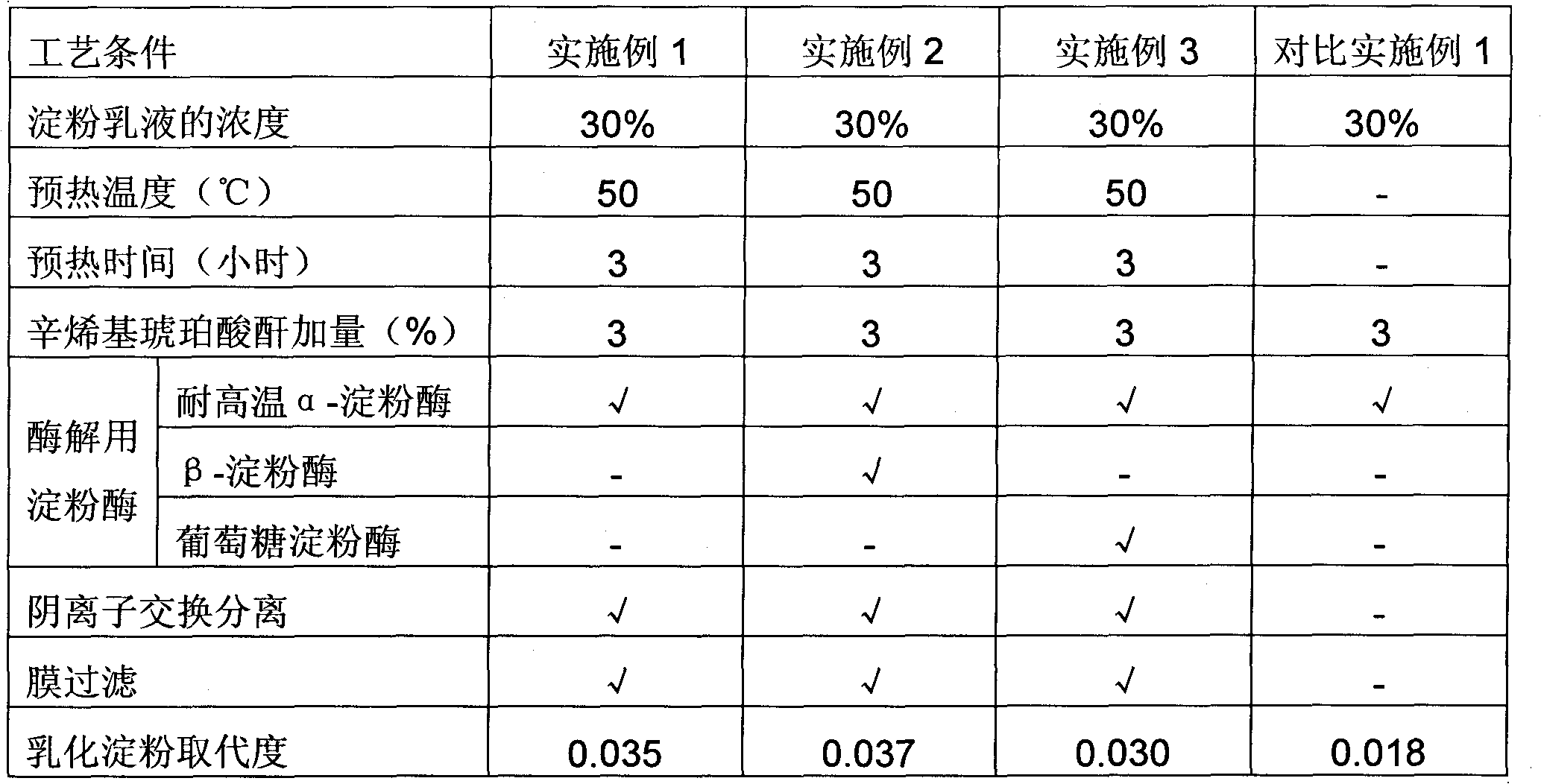

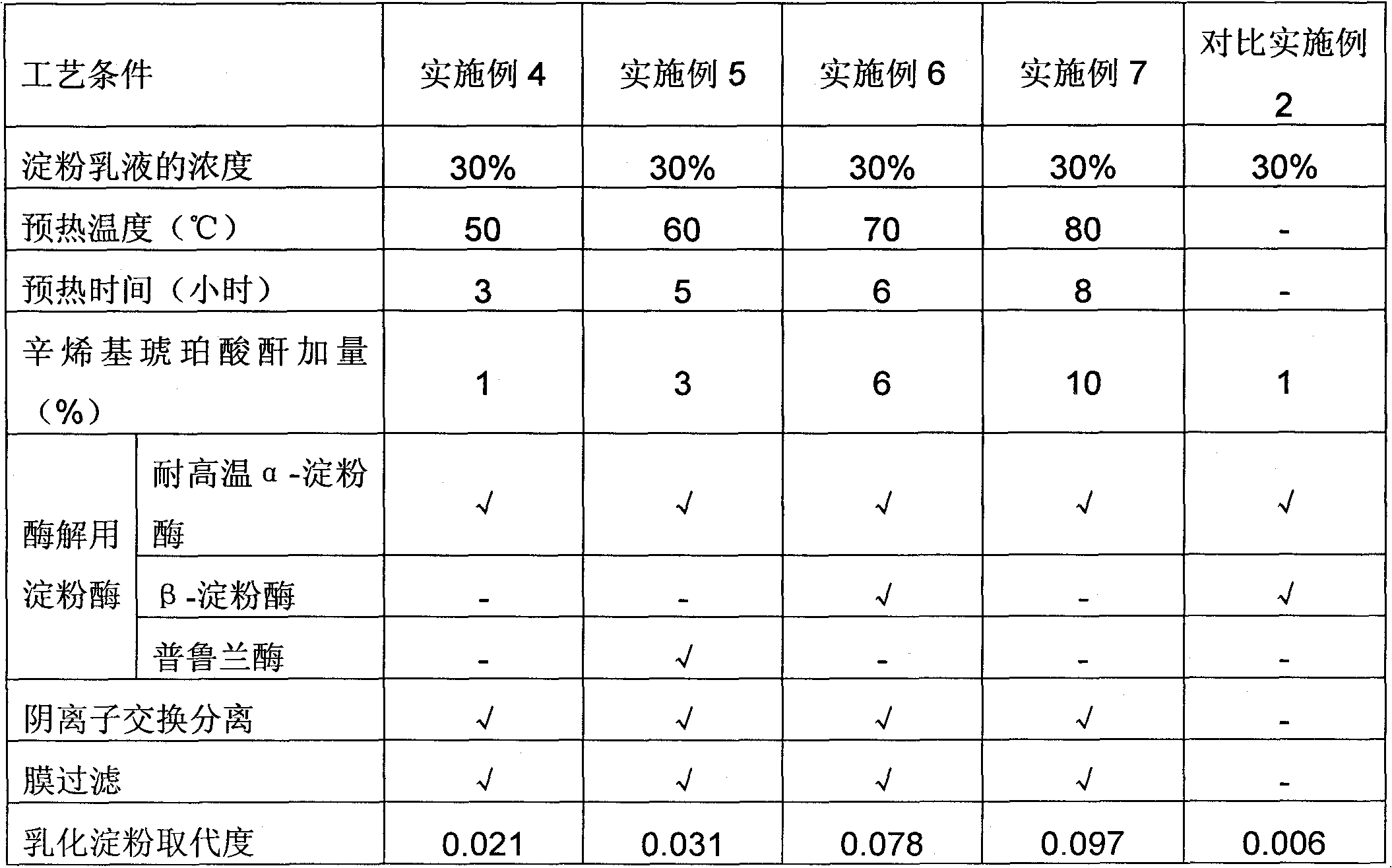

Examples

Embodiment 1

[0042] First, waxy cornstarch is added with water to adjust the milk, the concentration of the starch emulsion is 30% by mass, and preheated in a water bath at 50°C for 3 hours; the temperature of the starch milk is reduced to 35°C, and the sodium hydroxide solution with a mass percentage of 3% is used Adjust the pH value to 8.5, then add octenyl succinic anhydride accounting for 3% of the dry weight of the starch for reaction, and when the pH value does not change for half an hour, the reaction ends, and neutralize to pH 5.5 with 3% hydrochloric acid , centrifuged at a speed of 4000 rpm for 20 minutes, took the filter cake, washed the filter cake with water three times; added water to adjust the starch emulsion concentration to 25% by mass, added high-temperature-resistant α-amylase, and the amount of high-temperature-resistant α-amylase Be 10 activity units / g starch, heat to 100 ℃ and liquefy for 10 minutes, obtain the liquefaction liquid that the average polymerization degre...

Embodiment 2

[0044] First, waxy cornstarch is added with water to adjust the milk, the concentration of the starch emulsion is 30% by mass, and preheated in a water bath at 50°C for 3 hours; the temperature of the starch milk is reduced to 35°C, and the sodium hydroxide solution with a mass percentage of 3% is used Adjust the pH value to 8.5, then add octenyl succinic anhydride accounting for 3% of the dry weight of the starch for reaction, and when the pH value does not change for half an hour, the reaction ends, and neutralize with 3% hydrochloric acid to a pH value of 6.5, centrifuge at a speed of 3000 rpm for 30 minutes, take the filter cake, wash the filter cake with water three times; add water to adjust the starch emulsion concentration to 25% by mass, add high temperature resistant α-amylase, and add high temperature resistant α-amylase The amount is 10 activity units / g starch, heated to 100°C to liquefy for 10 minutes, cooled to 60°C after liquefaction, and then adding β-amylase, t...

Embodiment 8

[0051] First, waxy cornstarch is added with water to adjust the milk, the concentration of the starch emulsion is 30% by mass, and preheated in a water bath at 50°C for 3 hours; the temperature of the starch milk is reduced to 35°C, and the sodium hydroxide solution with a mass percentage of 3% is used Adjust the pH value to 8.5, and then add dodecenyl succinic anhydride accounting for 3% of the dry weight of the starch for reaction. When the pH value does not change for half an hour, the reaction ends, and neutralize to the pH value with 3% hydrochloric acid by mass percentage 6.5, centrifuged for 30 minutes at a speed of 3000 rpm, took the filter cake, washed the filter cake with water three times; added water to adjust the starch emulsion concentration to 25% by mass, added high temperature resistant α-amylase, high temperature resistant α-amylase Add 10 activity units / g starch, heat to 100°C to liquefy for 10 minutes, cool down to 60°C after liquefaction, then add β-amylase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com