Fruit and vegetable shelf small package bag film and manufacture method

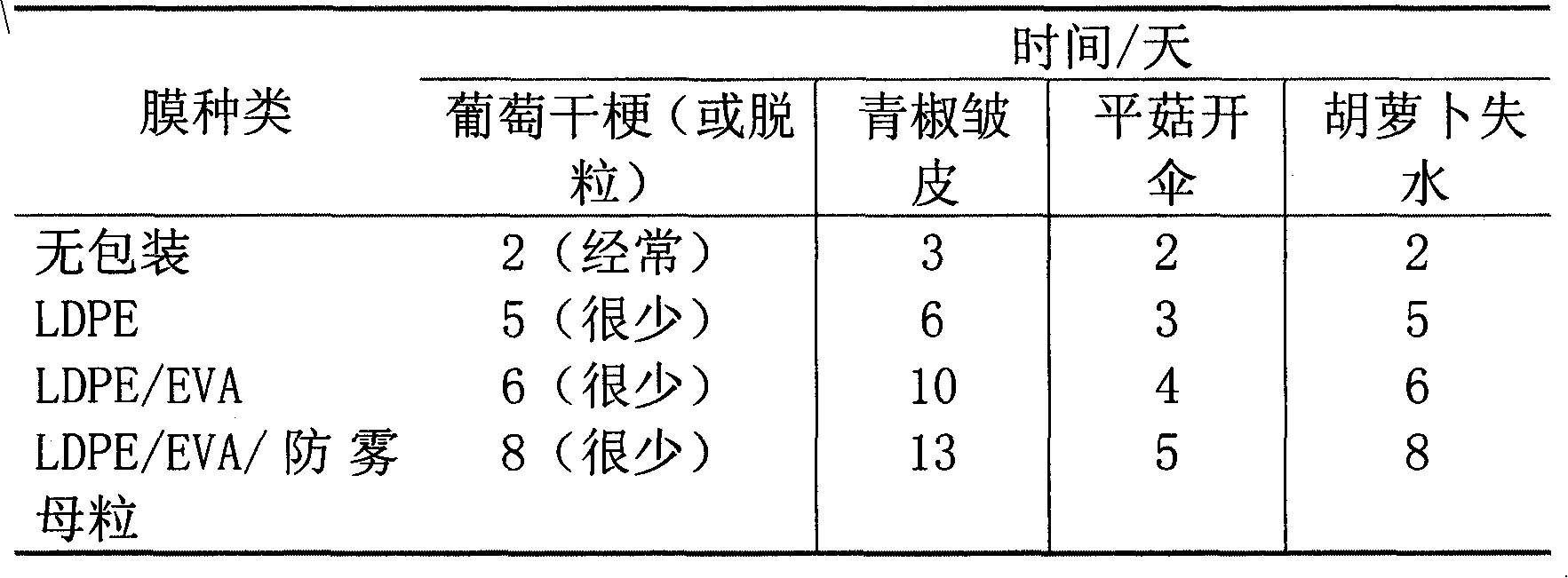

A packaging bag and shelf technology, applied in the field of small packaging bag film and production of fruit and vegetable shelves, can solve problems such as breakage, loss of water in fruit and vegetable products, and failure to achieve packaging of fruit and vegetable products, so as to reduce pollution, improve commodity value, and reduce wilting. The effect of dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0034] Make functional masterbatch first:

[0035] 10% short-term anti-fog functional masterbatch (10kg anti-fog material + 90kg polyethylene resin)

[0036] 20% antibacterial functional masterbatch (20kg antibacterial material + 80kg polyethylene resin)

[0037] It is completed by co-rotating parallel twin-screw extruder unit, and the operation process is as follows:

[0038] Masterbatch material

[0039] + Weighing → mixing → metering feeder → twin-screw extruder → strand cutting → masterbatch products

[0040] Base resin

[0041] Then carry out film and bag forming, using Φ50mm single-screw clip chain self-sealing bag film blowing machine and automatic bag making machine to complete, the operation process:

[0042] Base resin

[0043] + Weighing → plastic particle mixer → automatic feeding device → zipper ziplock bag film blowing machine → blowing

[0044] Auxiliary filler

[0045] Plastic film → printing → automatic bag making machine → (punching) → fin...

example 2

[0054] The formula can take

[0055] Linear polyethylene resin (LLDPE) 40-50 kg

[0056] Low-density polyethylene resin (LDPE) 20-25 kg

[0057] Ethylene-vinyl acetate resin (EVA) 16-20 kg

[0058] 10% short-acting anti-fog functional masterbatch 5-10 kg

[0059] 20% antibacterial functional masterbatch 4-8 kg

example 3

[0061] The best formulations are:

[0062] By weight,:

[0063] Linear polyethylene resin (LLDPE) 48 kg

[0064] Low-density polyethylene resin (LDPE) 24 kg

[0065] Ethylene-vinyl acetate resin (EVA) 15 kg

[0066] 10% short-acting anti-fog functional masterbatch 8kg

[0067] 20% antibacterial functional masterbatch 5 kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com