Polyester composition and polyester film

A composition and polyester technology, applied in the field of oriented polyester film, can solve the problems of long polymerization time, reduced catalyst activity, black appearance of polyester, etc., and achieve the effect of superior optical properties and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0121] (1) Preparation of polycondensation catalyst solution

[0122] (Preparation of aqueous solution of aluminum compound)

[0123] At normal temperature and normal pressure, 5.0 liters of pure water was added to a beaker equipped with a cooling tube, and then, while stirring at 200 rpm, 200 g of basic aluminum acetate was added as a slurry with pure water. Furthermore, pure water was added so that it might become 10.0 liters as a whole, and it stirred for 12 hours at normal temperature and normal pressure. Then, the jacket temperature was changed to 100.5° C. to raise the temperature, and the mixture was stirred under reflux for 3 hours from the time when the internal temperature became 95° C. or higher. Stirring was stopped and cooled to room temperature to obtain an aqueous solution.

[0124] (Preparation of ethylene glycol mixed solution of aluminum compound)

[0125] Add an equal volume of ethylene glycol to the aluminum compound aqueous solution obtained by the abov...

Embodiment 2

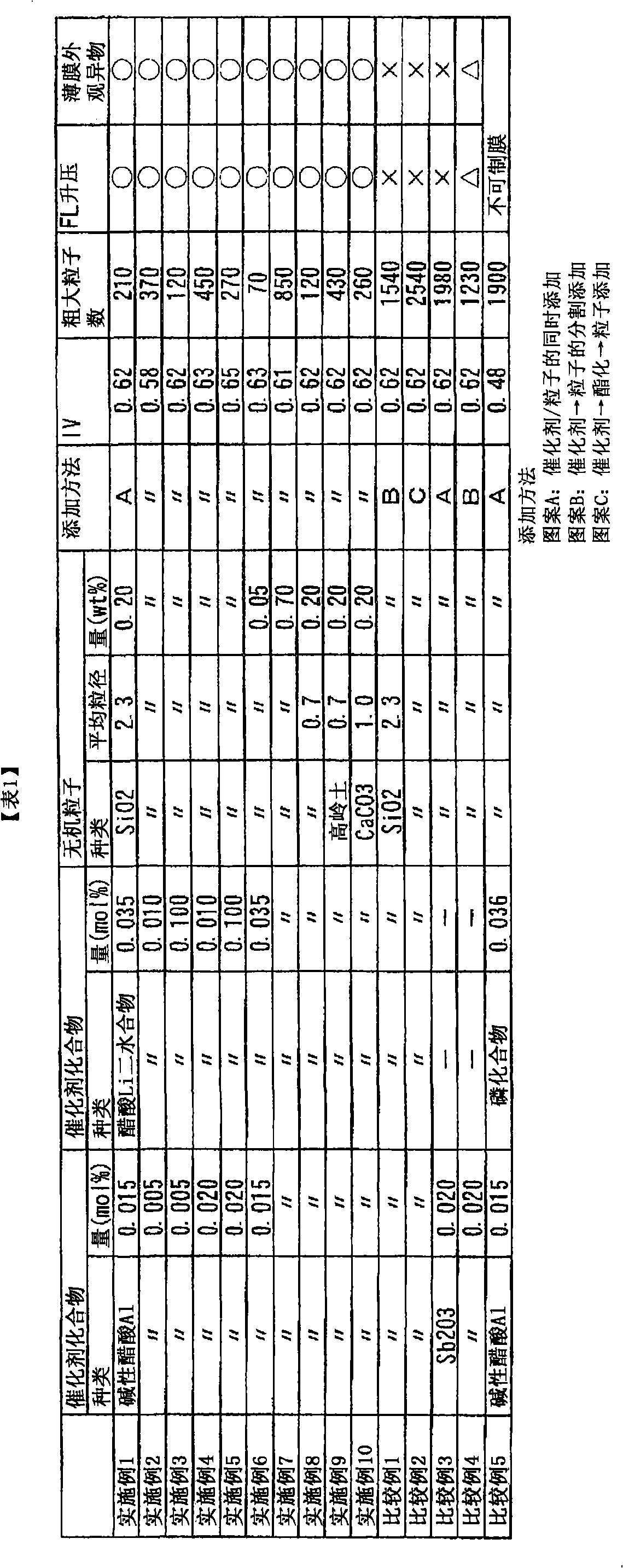

[0136] In the polymerization method of Example 1, the addition amount of the aluminum compound and the lithium compound is set to 0.005 mol% and 0.010 mol% of the aluminum atom and the lithium atom relative to the acid component in the polyester. The same method of example 1, obtained the polyester of IV0.58. The characteristic values of the obtained polyesters are shown in Table 1. The content of silica particles in the obtained polyester was 0.20% by weight, and the number of coarse particles of 10 μm or more was 370 / mm 2 . The obtained polyester sheet was formed into a film by the same method as in Example 1 to obtain a polyester film. The properties of the obtained films are shown in Table 1.

Embodiment 3

[0138] In the polymerization method of Example 1, the addition amount of the aluminum compound and the lithium compound is set to 0.005 mol% and 0.100 mol% of the aluminum atom and the lithium atom relative to the acid component in the polyester. The same method of example 1, obtained the polyester of IV0.62. The characteristic values of the obtained polyesters are shown in Table 1. The content of silica particles in the obtained polyester was 0.20% by weight, and the number of coarse particles of 10 μm or more was 120 / mm 2 . The obtained polyester sheet was formed into a film by the same method as in Example 1 to obtain a polyester film. The properties of the obtained films are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com