Wire-tube refrigerating evaporator

A refrigerated evaporator and silk tube technology, which is applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems that the product cannot meet the needs of customers and consumers, increase energy consumption, and low cooling capacity, etc. Achieve the effects of improving cooling effect, reducing running time, increasing cooling surface and cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

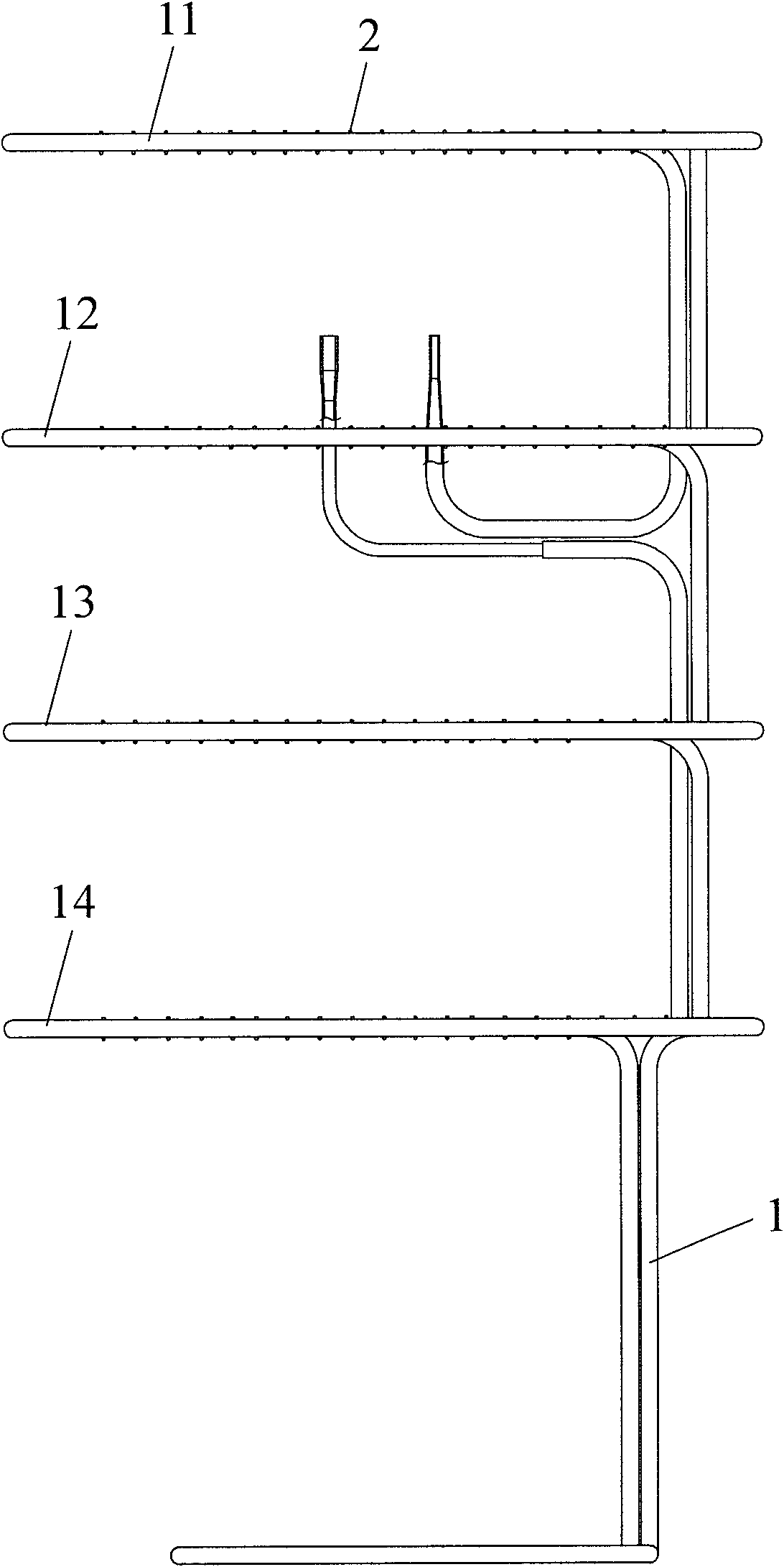

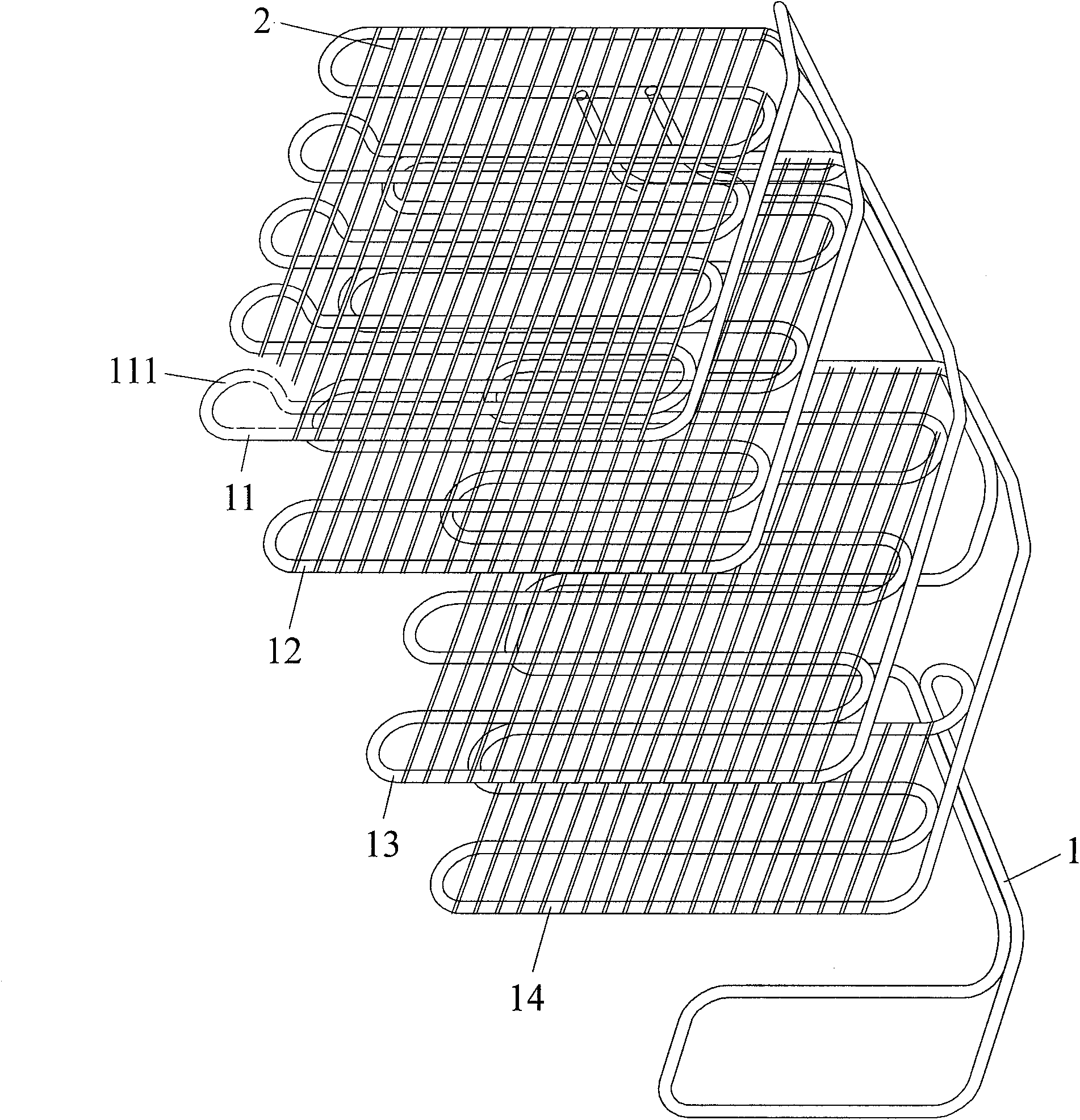

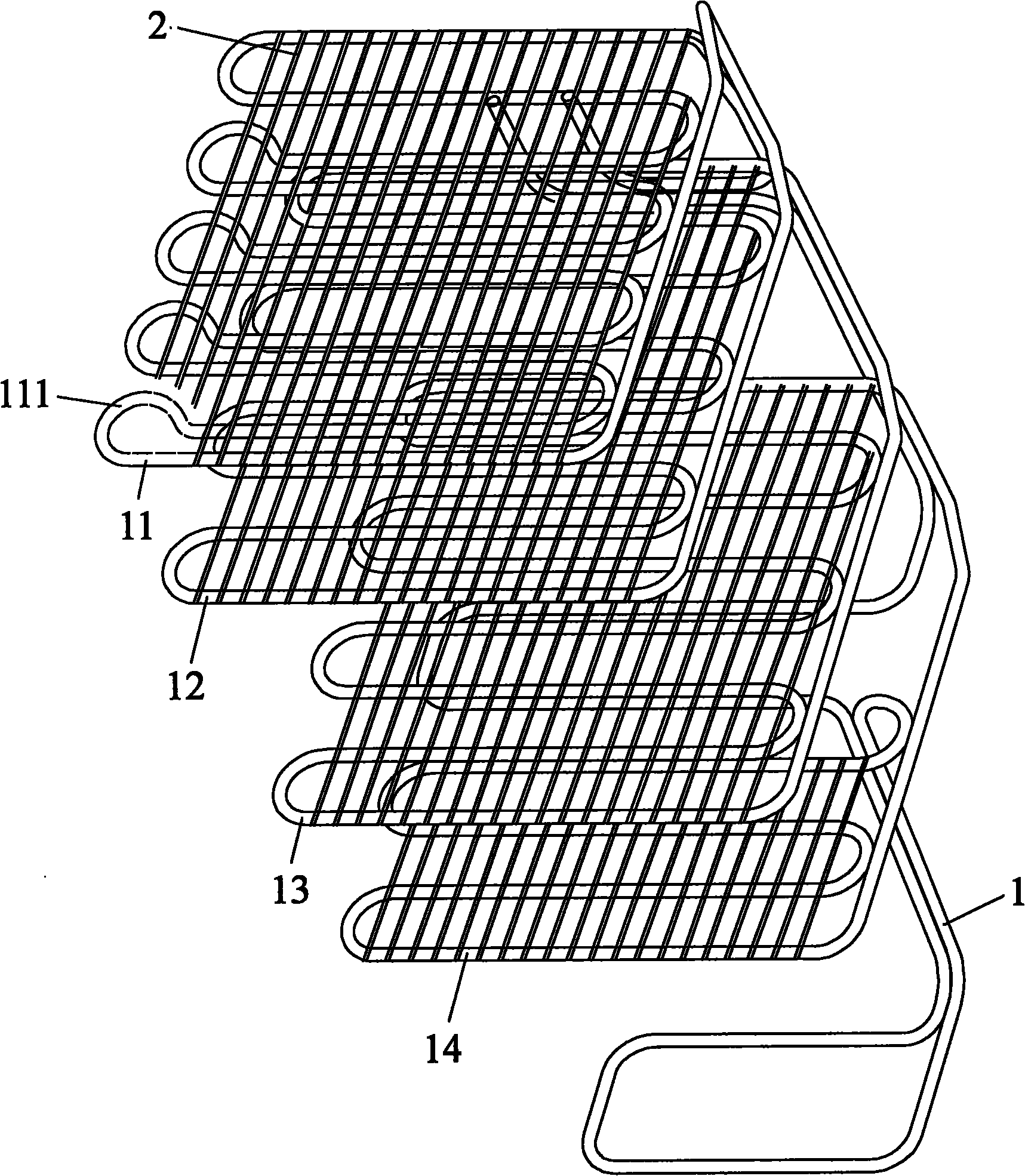

[0012] See figure 1 , 2 As shown: the silk tube type refrigeration evaporator, which is composed of an evaporation tube 1 and an evaporation wire 2. The evaporation tube 1 is fixedly connected to the evaporation wire 2. It is characterized in that: the evaporation tube 1 is wound into no less than two parallel layers of evaporation tubes 11, 12, 13, 14.

[0013] Some of the upper bending parts of the evaporating tubes 11, 12, 13, 14 of each layer are in the shape of "9".

[0014] The evaporating tube 1 is wound into four parallel layers, that is, the first layer of evaporating tubes 11 , the second layer of evaporating tubes 12 , the third layer of evaporating tubes 13 and the fourth layer of evaporating tubes 14 .

[0015] Working principle: when the width of the evaporator is relatively fixed, the present in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap