High-temperature sodium heat-convection test loop

A test circuit and high-temperature test technology, which is applied in the field of material corrosion, can solve problems such as damage, impossibility of gas phase test, and high impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The technical solution of the present invention will be further elaborated below in conjunction with the accompanying drawings.

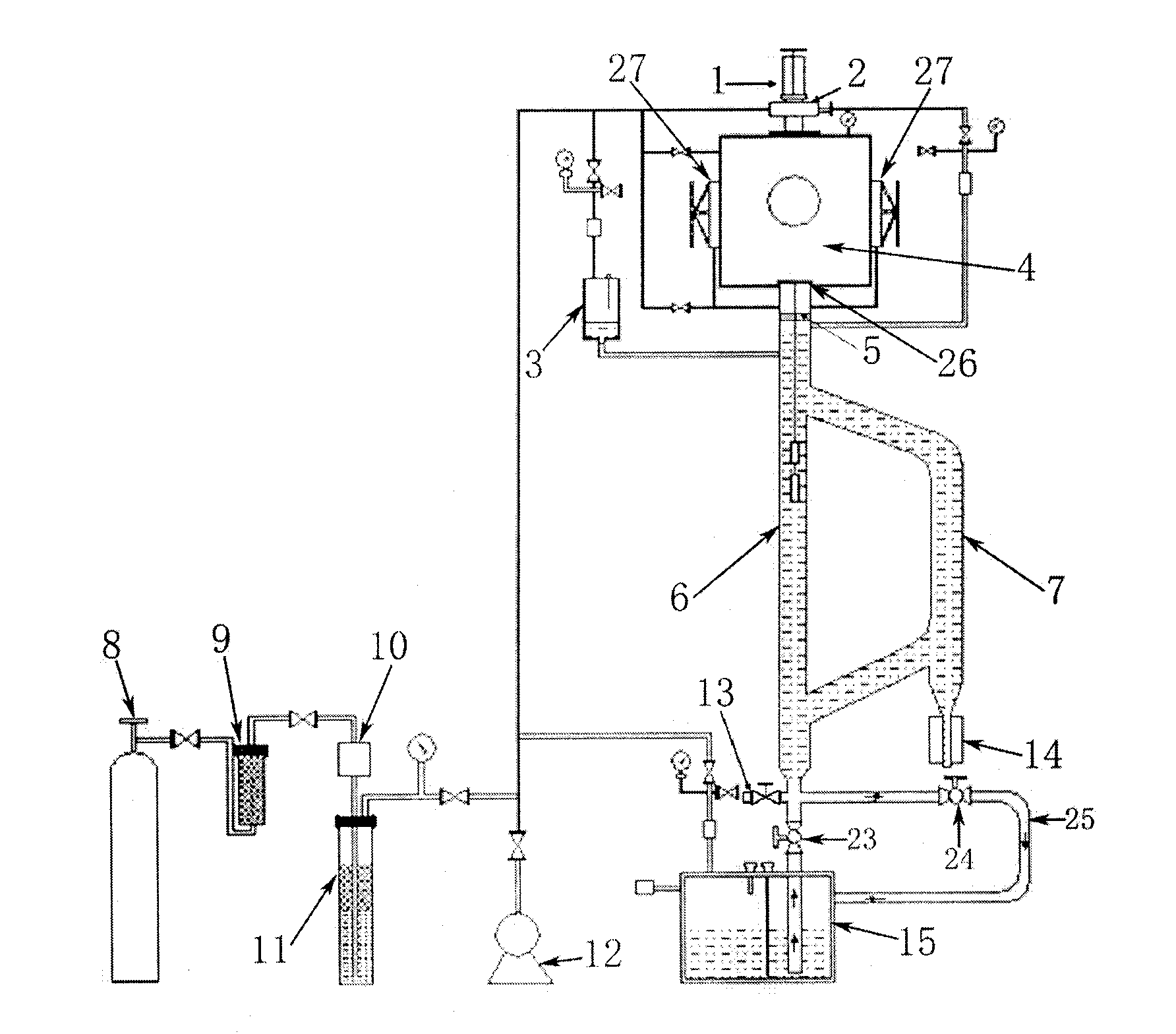

[0020] Such as figure 1 As shown, the high-temperature sodium heat convection test circuit provided by the present invention includes a main circuit system, a sodium storage tank 15, a sodium intake and discharge system, a covering gas purification and vacuum system, a sampling box 4 and a temperature control system, wherein the main circuit system It is composed of the circuit body, expansion tank 3 and cold trap 14. The circuit body adopts a vertical quadrilateral structure, and the circulation circuit is composed of the high temperature test section 6, the low temperature section 7 and the upper and lower horizontal pipes. The expansion tank 3 is at the highest point of the main circuit system. The expansion tank 3 is provided with a liquid level gauge and an alarm device, and a finger-shaped diffusion cold trap 14 is provided at the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com