Method for processing wafer

A processing method and technology for wafers, which are applied in metal processing equipment, manufacturing tools, machine tools suitable for grinding workpiece planes, etc., can solve problems such as easy breakage of wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

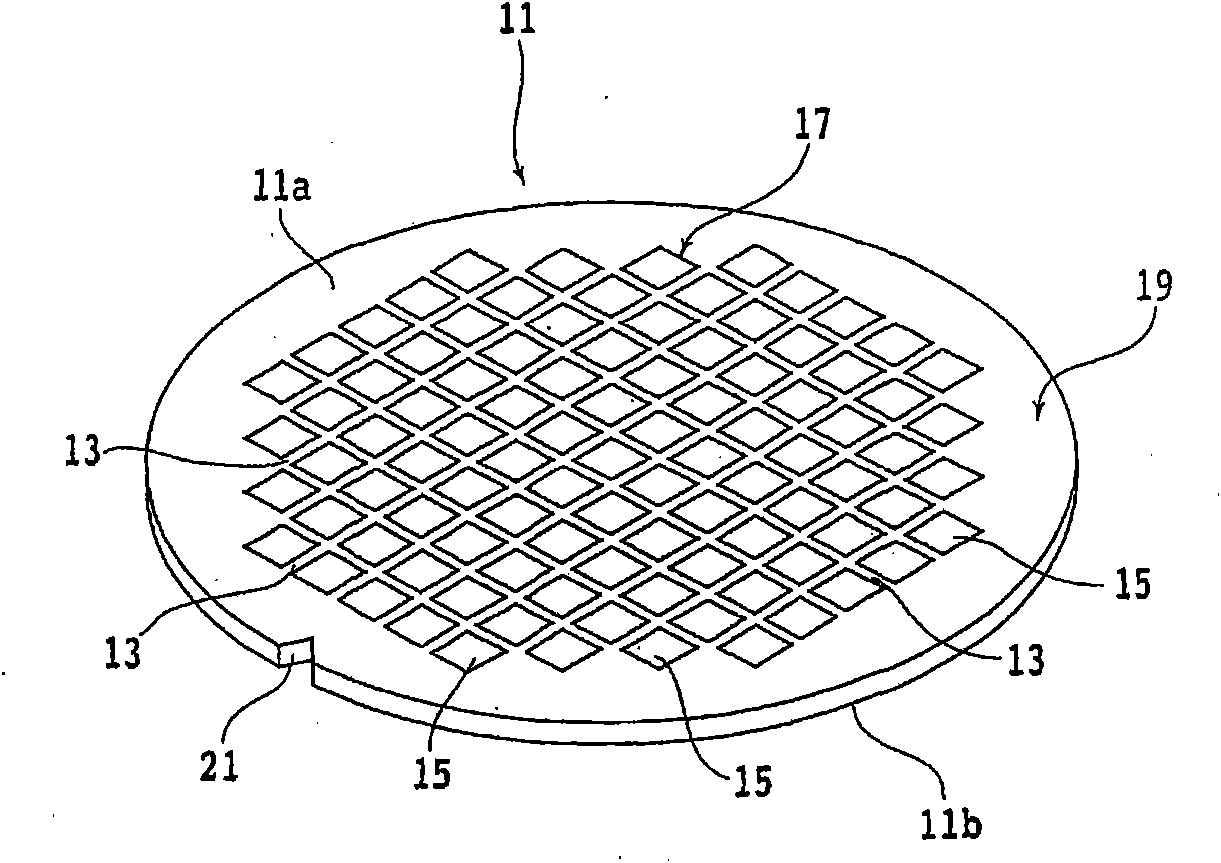

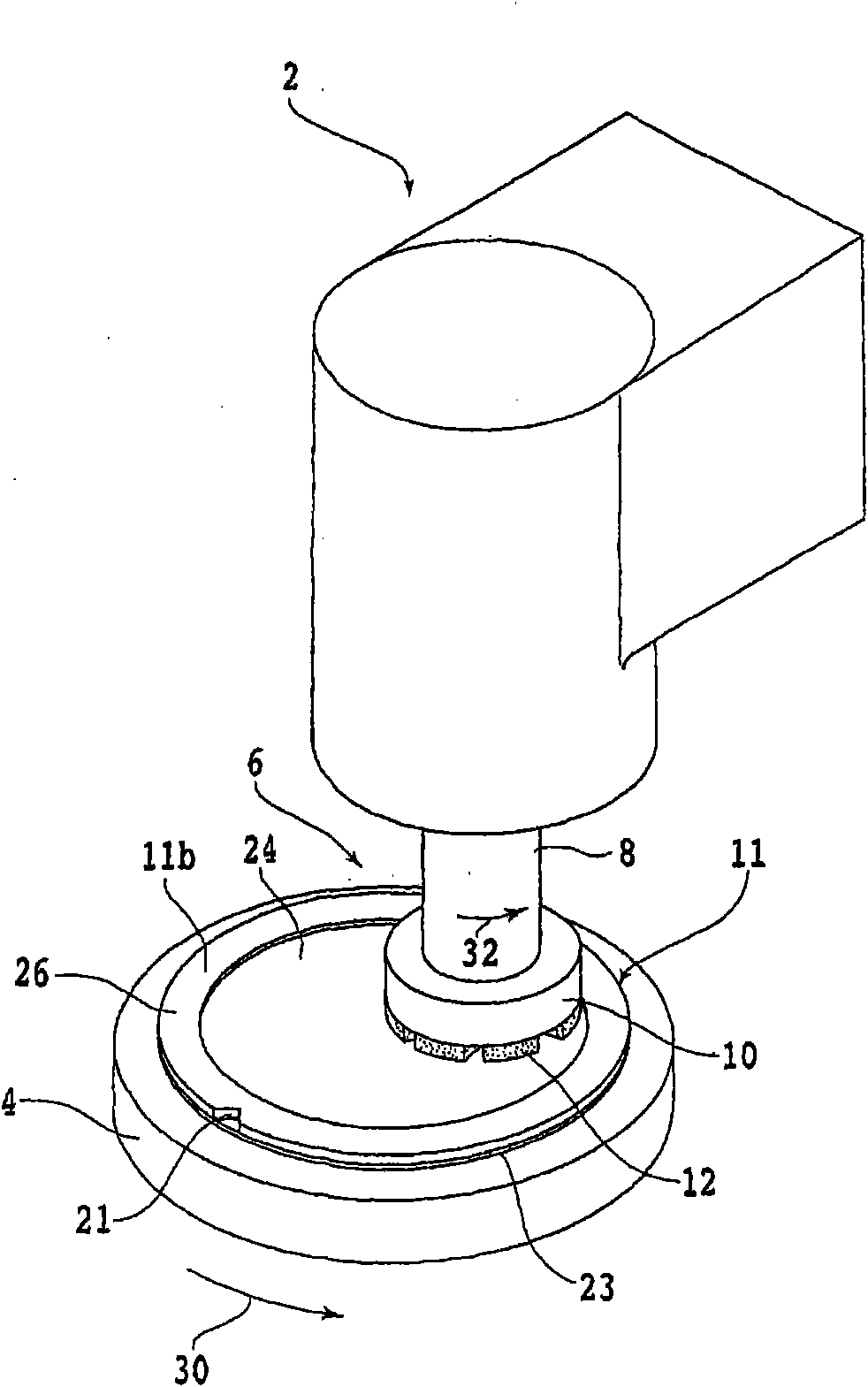

[0026] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. figure 1 It is a perspective view of a semiconductor wafer before processing to a predetermined thickness. figure 1 The shown semiconductor wafer 11 is made of, for example, a silicon wafer with a thickness of 700 μm, and a plurality of partitions 13 are formed in a grid pattern on the surface 11 a, and ICs are formed in a plurality of regions divided by the plurality of partitions 13 . , LSI and other devices 15.

[0027] The semiconductor wafer 11 thus constituted has a device region 17 in which the device 15 is formed, and a peripheral remaining region 19 surrounding the device region 17 . Further, on the outer periphery of the semiconductor wafer 11, a notch 21 is formed as a mark indicating the crystal orientation of the silicon wafer.

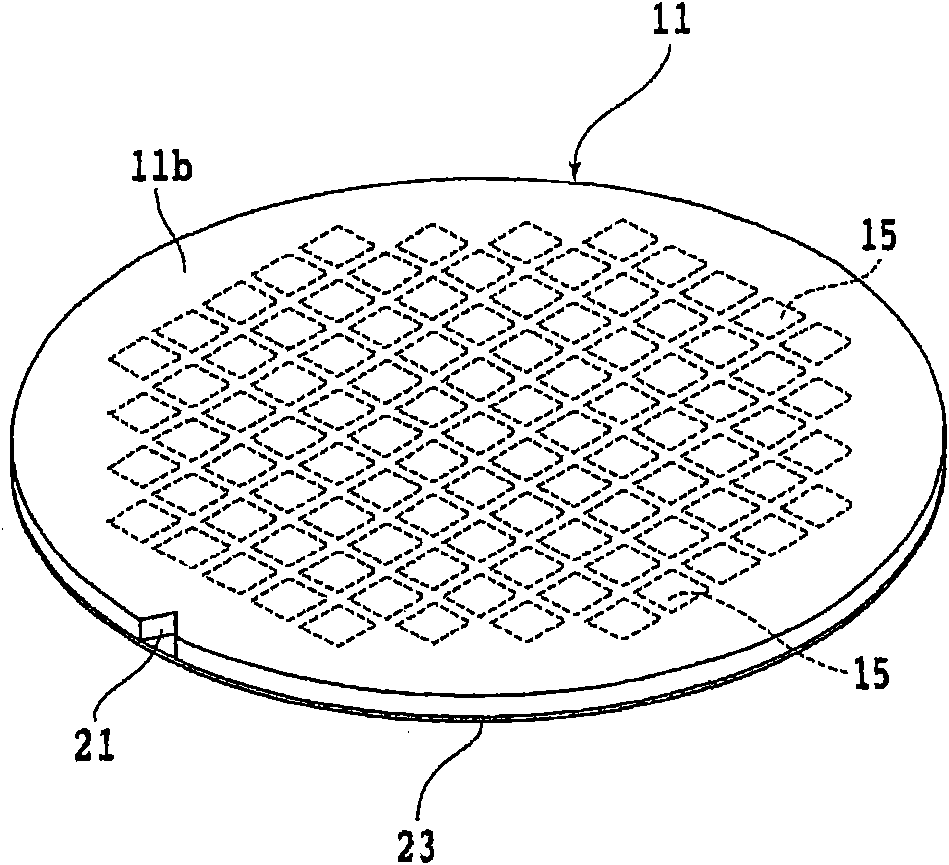

[0028] On the surface 11a of the semiconductor wafer 11, the protective tape 23 is pasted in a protective tape pasting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com