High-performance epoxy zinc-rich antirust primer and preparation method thereof

An epoxy zinc-rich, anti-rust primer technology, applied in the field of coatings, can solve problems such as environmental protection and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

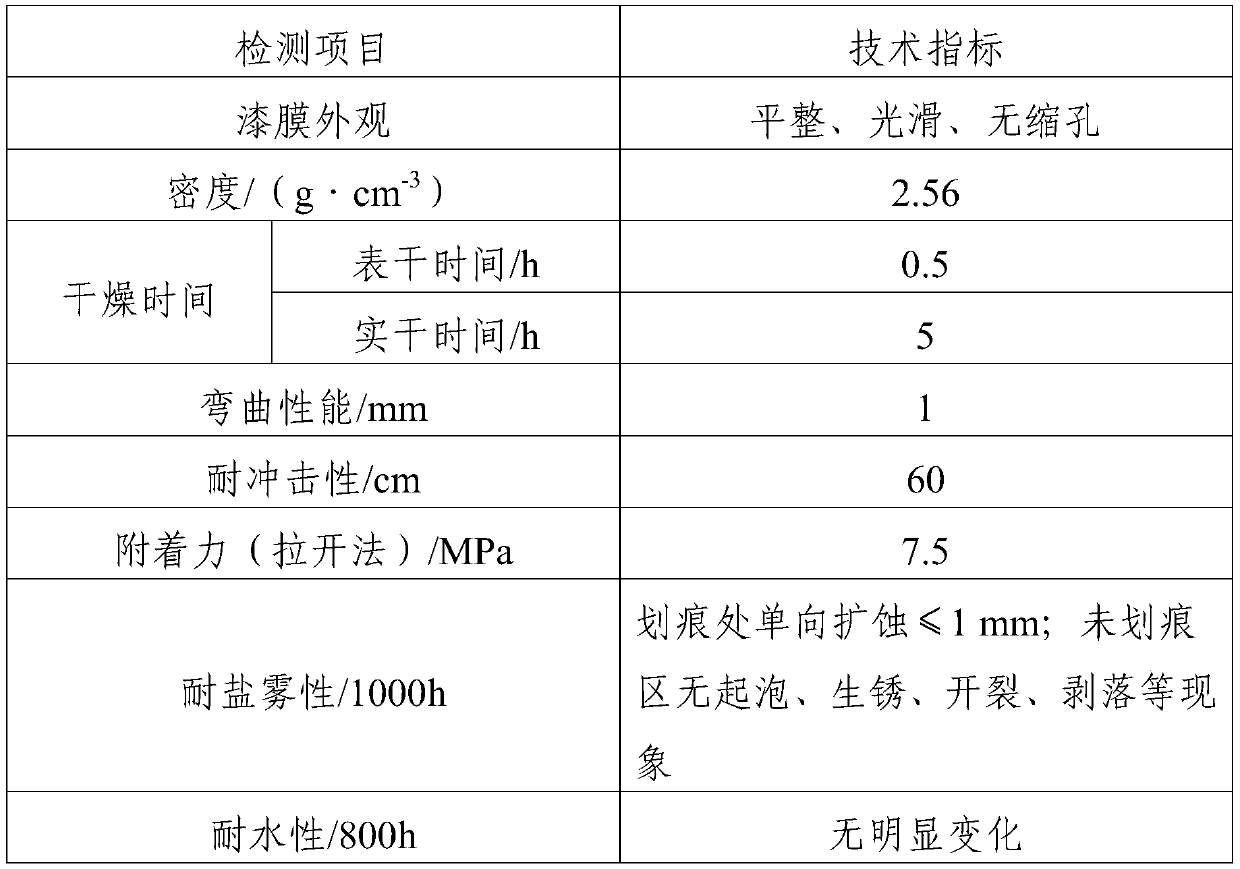

Image

Examples

Embodiment 1

[0038] A high-performance epoxy zinc-rich antirust primer, including A component and B component, the weight ratio of A component and B component is 12:1, wherein, A component includes the following components in parts by weight :

[0039] 12 parts of water-based epoxy resin, 6 parts of organic bentonite, 2 parts of polyamide wax paste, 52 parts of zinc powder, 8 parts of rare earth praseodymium powder, 3 parts of polymerized iron phosphorus powder, 11 parts of fumed silica, TEGO-KL245 high-efficiency substrate 0.5 parts of wetting agent, 1.2 parts of R-760F water-based anti-flash rust agent, 1 part of polyol type nonionic surfactant dispersant, 0.4 parts of castor oil derivative anti-settling agent, 3 parts of cellulose derivative, n-butanol 5 parts, 105 parts of water;

[0040]Component B includes the following ingredients in parts by weight:

[0041] 45 parts of cashew nut shell oil modified polyamide curing agent, 7 parts of CMP-410 epoxy resin active toughening agent, 2...

Embodiment 2

[0045] A high-performance epoxy zinc-rich antirust primer, including A component and B component, the weight ratio of A component and B component is 10:1, wherein, A component includes the following components in parts by weight :

[0046] 15 parts of water-based epoxy resin, 7 parts of organic bentonite, 1 part of polyamide wax paste, 50 parts of zinc powder, 5 parts of rare earth praseodymium powder, 3 parts of polymerized iron phosphorus powder, 12 parts of fumed silica, TEGO-KL245 high-efficiency substrate 0.3 parts of wetting agent, 1.5 parts of R-760F water-based anti-flash rust agent, 1.5 parts of polyol type nonionic surfactant dispersant, 0.5 parts of castor oil derivative anti-settling agent, 1 part of cellulose derivative, n-butanol 5 parts, 100 parts of water;

[0047] Component B includes the following ingredients in parts by weight:

[0048] 45 parts of cashew nut shell oil modified polyamide curing agent, 5 parts of CMP-410 epoxy resin active toughening agent,...

Embodiment 3

[0052] A high-performance epoxy zinc-rich antirust primer, including A component and B component, the weight ratio of A component and B component is 8:1, wherein, A component includes the following components in parts by weight :

[0053] 10 parts of water-based epoxy resin, 5 parts of organic bentonite, 1 part of polyamide wax paste, 50 parts of zinc powder, 5 parts of rare earth praseodymium powder, 3 parts of polymerized ferrophosphorus powder, 10 parts of fumed silica, TEGO-KL245 high-efficiency substrate 0.5 parts of wetting agent, 1.2 parts of R-760F water-based anti-flash rust agent, 0.8 parts of polyol type nonionic surfactant dispersant, 0.5 parts of castor oil derivative anti-settling agent, 1 part of cellulose derivative, n-butanol 5 parts, 100 parts of water;

[0054] Component B includes the following ingredients in parts by weight:

[0055] Cashew nut shell oil modified polyamide curing agent 55 parts, CMP-410 epoxy resin active toughening agent 6 parts, methyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com