One-step method for producing high-nitrogen austenitic stainless steel

A nitrogen austenitic and stainless steel technology, applied in the field of one-step production of high-nitrogen austenitic stainless steel, can solve the problems of complex smelting methods of high-nitrogen austenitic stainless steel, high-nitrogen stainless steel casting products cannot be popularized and applied, and meet the technological conditions Easy-to-control, simple-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

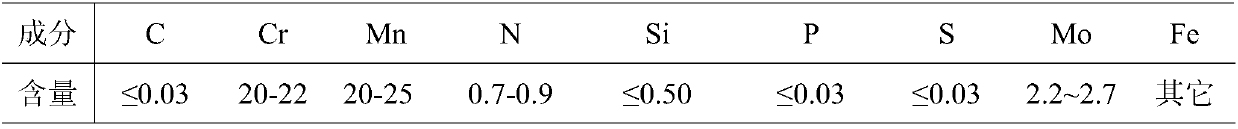

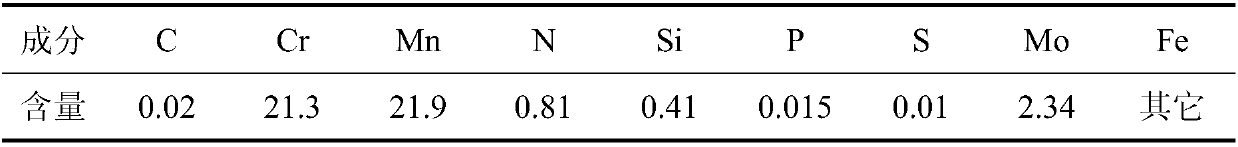

[0016] Take smelting 100kg Cr21Mn22Mo2.5N0.8 high-nitrogen austenitic stainless steel as an example, the chemical composition of high-nitrogen steel is as follows (%, percent by weight):

[0017]

[0018] The method for producing high-nitrogen austenitic stainless steel by one-step method specifically includes the following steps:

[0019] (1), chromium-containing scrap (Cr13 scrap) and manganese-containing scrap (20Mn23Al scrap) are added to the electric furnace for smelting, the manganese content is controlled to be 10-20%, and the chromium content is 15%-24%; then the molten steel is transferred to nitrogen Oxygen refining furnace refining station for refining, control the temperature of molten steel at 1470-1520°C, feed nitrogen throughout the refining process, and control the flow of nitrogen at 1800-2000Nm 3 / h;

[0020] (2) Fix the position of the top lance at 2.8 meters, control the temperature of the top lance at 1650-1680°C, and carry out the oxygen blowing decar...

Embodiment 2

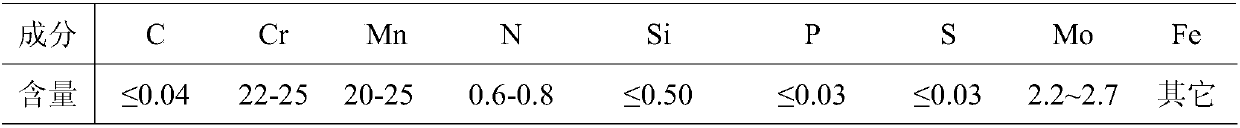

[0025] Take smelting 100kg Cr23Mn21Mo2.5N0.7 high-nitrogen austenitic stainless steel as an example, the chemical composition of high-nitrogen steel is as follows (%, weight percentage):

[0026]

[0027] The method for producing high-nitrogen austenitic stainless steel by one-step method specifically includes the following steps:

[0028] (1), chromium-containing scrap steel (high carbon ferrochrome) and manganese-containing scrap steel (20Mn23Al scrap steel) are added to the electric furnace for smelting, and the manganese content is controlled to be 16-20%, and the chromium content is 20%-24%; then the molten steel is transferred to Go to the refining station of nitrogen and oxygen refining furnace for refining, control the temperature of molten steel at 1490-1520°C, feed nitrogen throughout the refining process, and control the flow rate of nitrogen at 1920-2000Nm 3 / h;

[0029] (2) Fix the position of the top lance at 2.8 meters, control the temperature of the top lan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com