Fuel cell system and method for starting the fuel cell system

A fuel cell system and start-up method technology, which is applied in the direction of fuel cells, fuel cell additives, solid electrolyte fuel cells, etc., can solve the problems of necessary heat source and high reaction temperature, and achieve the effect of preventing oxidation and deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

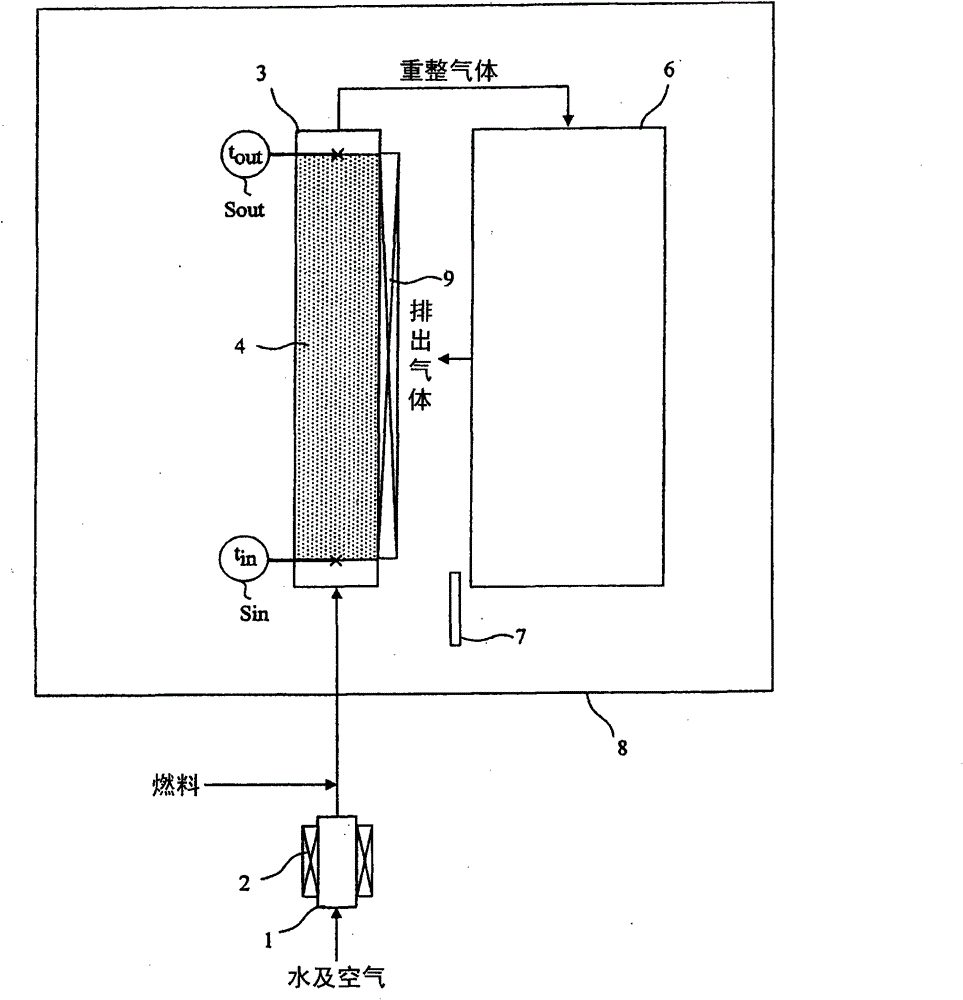

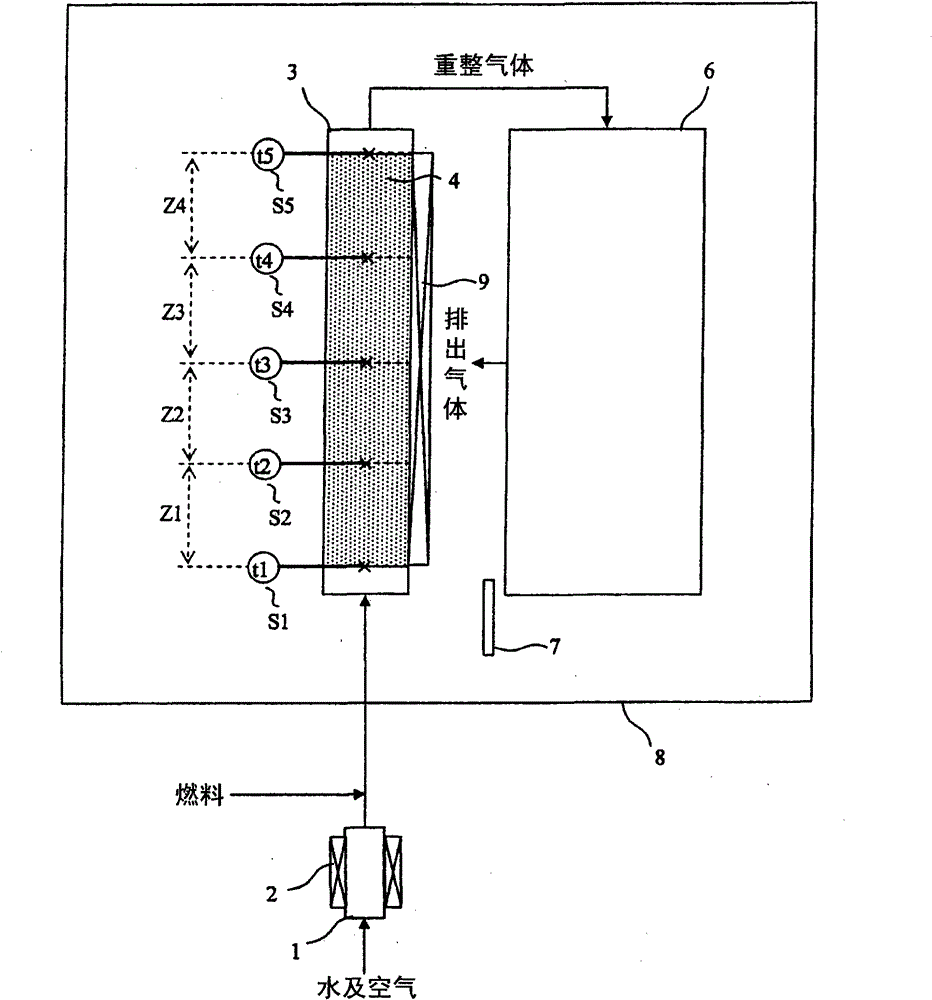

[0048] The fuel cell system used in the present invention has a reformer for reforming hydrocarbon-based fuel to produce hydrogen-containing gas and a high-temperature fuel cell. The reformer has a reforming catalyst layer. High-temperature fuel cells use the hydrogen-containing gas obtained from the reformer to generate electricity. The reforming catalyst layer is composed of a reforming catalyst that promotes a reforming reaction. The hydrogen-containing gas obtained from the reformer is called reformed gas.

[0049] (Process a)

[0050] When the fuel cell system is actually started, step a is performed. That is, the temperature of the reforming catalyst layer is raised while measuring the temperature of the reforming catalyst layer. The temperature measurement and temperature rise in step a are continued until the start-up is completed.

[0051] As a heat source for this temperature increase, for example, an electric heater provided in a reformer can be used.

[0052]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com