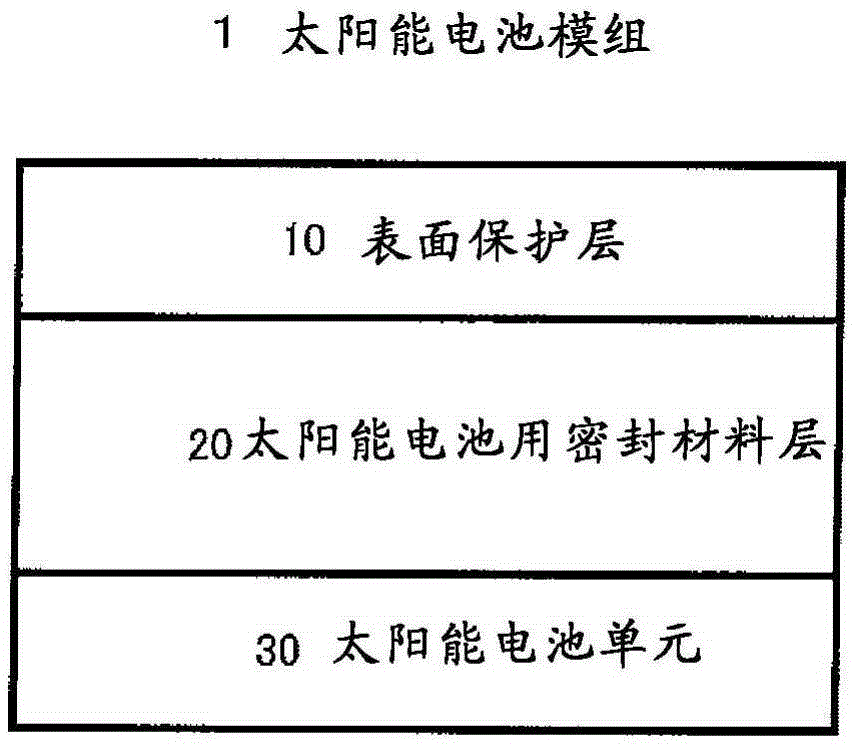

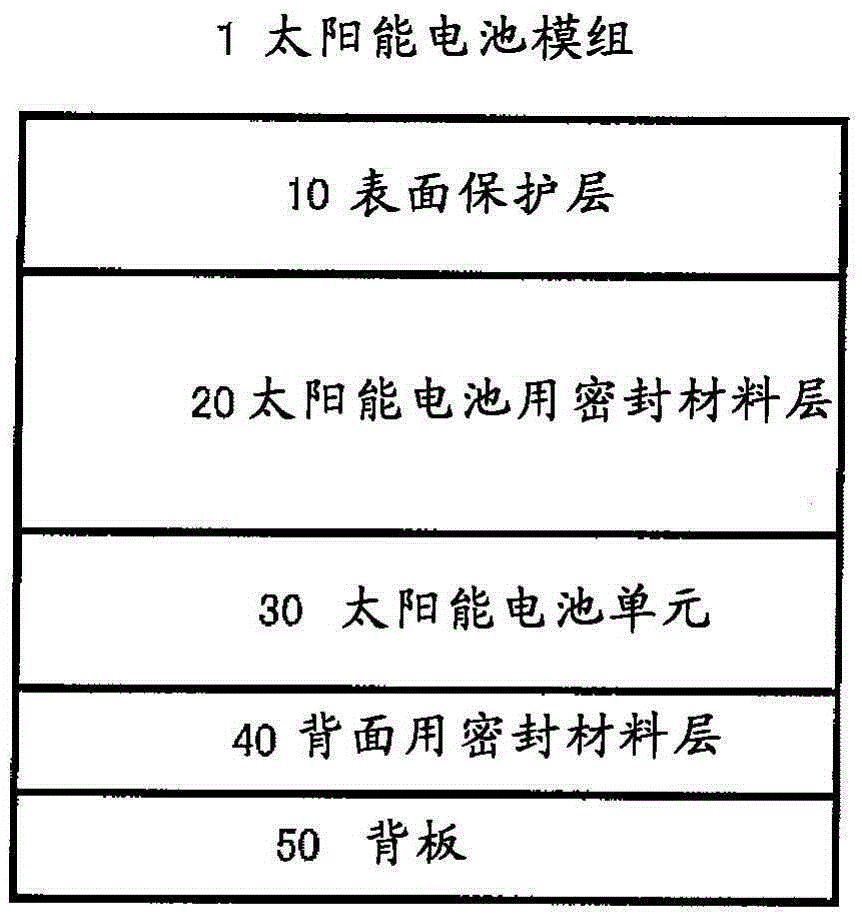

Sealing material composition for solar cells, sealing material layer for solar cells, and solar cell module using same

A technology for solar cells and sealing materials, which is applied in the field of sealing material layer compositions, can solve problems such as loss of sealing material layer properties, reduction of cross-linkability, degradation of matrix resin, etc., achieve sufficient cross-linking and curing, prevent oxidation degradation, and inhibit oxidation The effect of deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

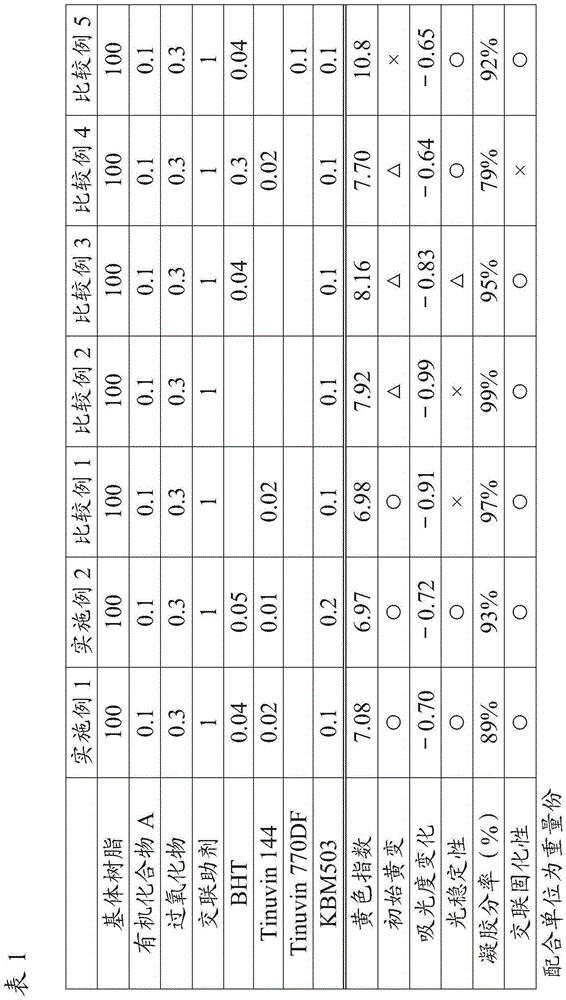

[0093] Hereinafter, Examples etc. which specifically show the structure and effect of this invention are demonstrated.

[0094] (compounds in the table)

[0095] In Examples and Comparative Examples, the following compounds were used.

[0096] ・Base resin: SUMITATEKA-30, ethylene vinyl acetate resin (manufactured by Sumitomo Chemical Co., Ltd.)

[0097] Organic compound A: 4,7-bis(4-isobutyloxyphenyl)-2-isobutyl-2H-benzotriazole

[0098] · Peroxide: peroxy-2-ethylhexyl monocarbonate tert-butyl (manufactured by NOF Corporation, Perbutyl E)

[0099] ・Crosslinking aid: triallyl isocyanurate (manufactured by Nippon Kasei Co., Ltd., TAIC)

[0100] ・BHT: Dibutylhydroxytoluene (manufactured by Tokyo Chemical Industry Co., Ltd.)

[0101] Tinuvin144: [[3,5-bis(1,1-dimethylethyl)-4-hydroxyphenyl]methyl]butylmalonate bis(1,2,2,6,6-pentamethyl Cyl-4-piperidinyl) ester (manufactured by BASF, molecular weight 685)

[0102] · Tinuvin770DF: bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com