Semiconductor device manufacturing method and bonding assembly device

A manufacturing method and a technology for assembling devices, which are applied in semiconductor/solid-state device manufacturing, semiconductor devices, manufacturing tools, etc., can solve problems such as reduced heat dissipation characteristics, damage to semiconductor devices, and hindrance to heat dissipation, so as to reduce environmental loads, eliminate deviations, and prevent The effect of bad joint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

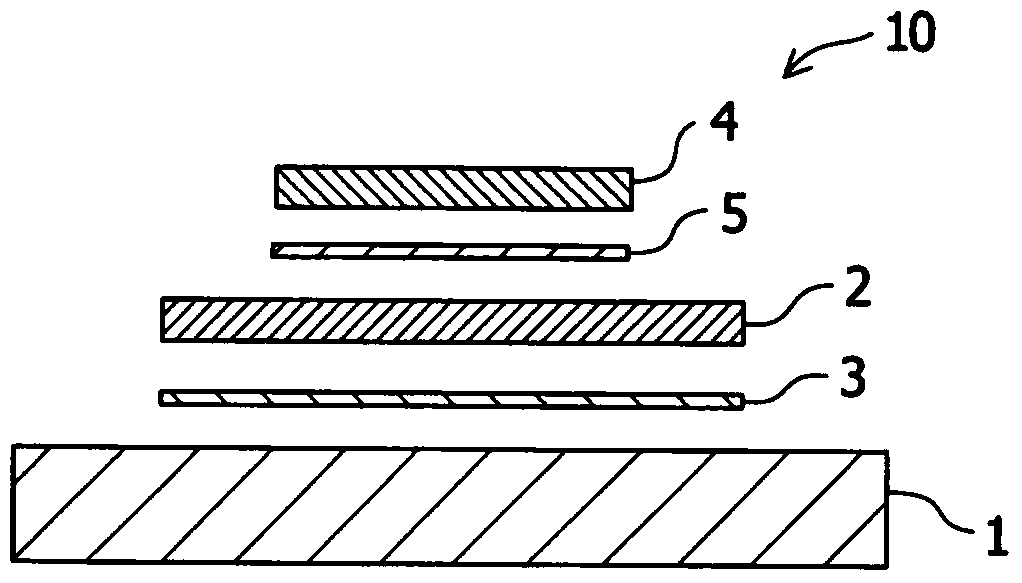

[0041] Hereinafter, embodiments of the present invention will be described with reference to the drawings. However, the present invention is not limited by the embodiments described below.

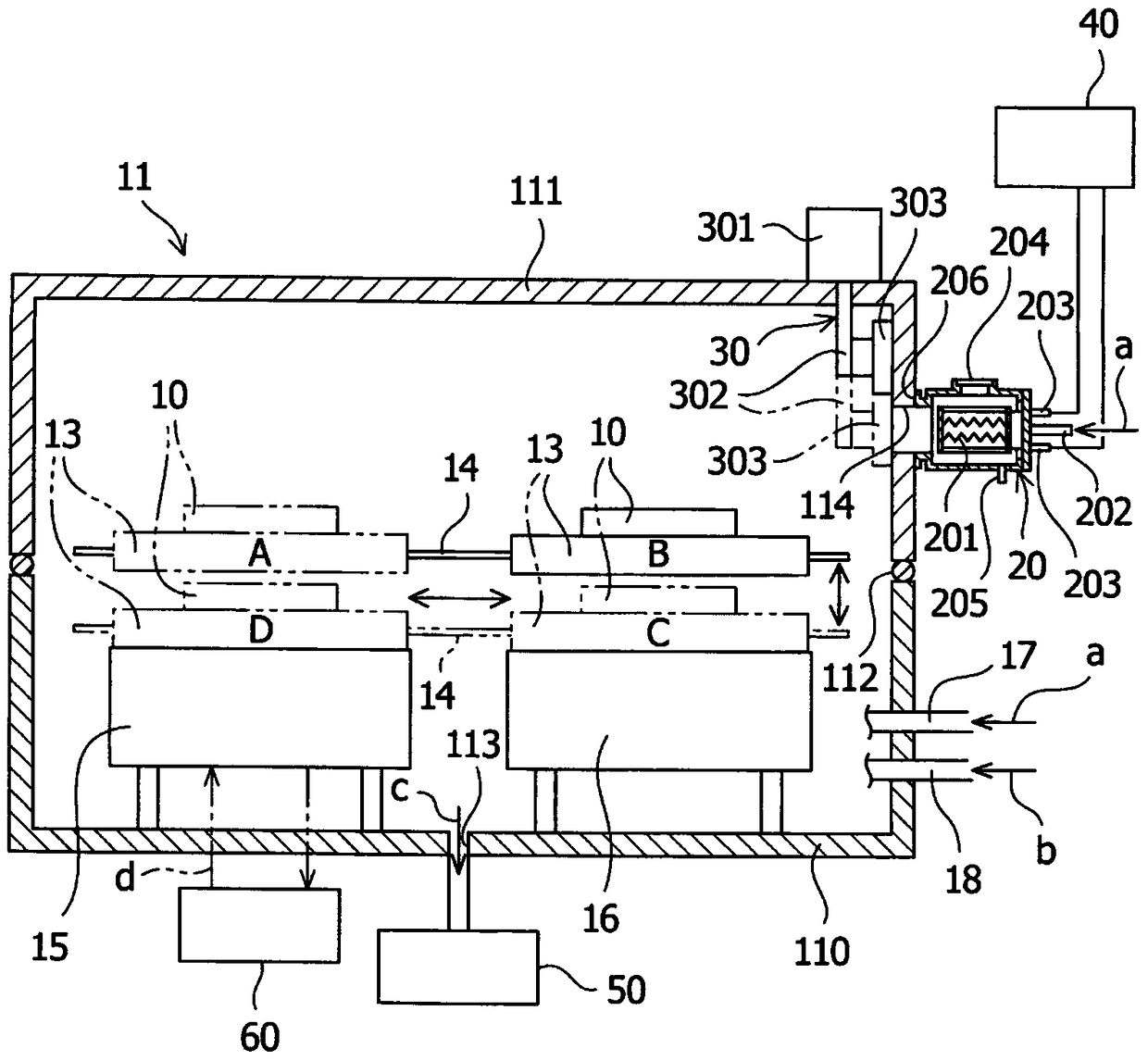

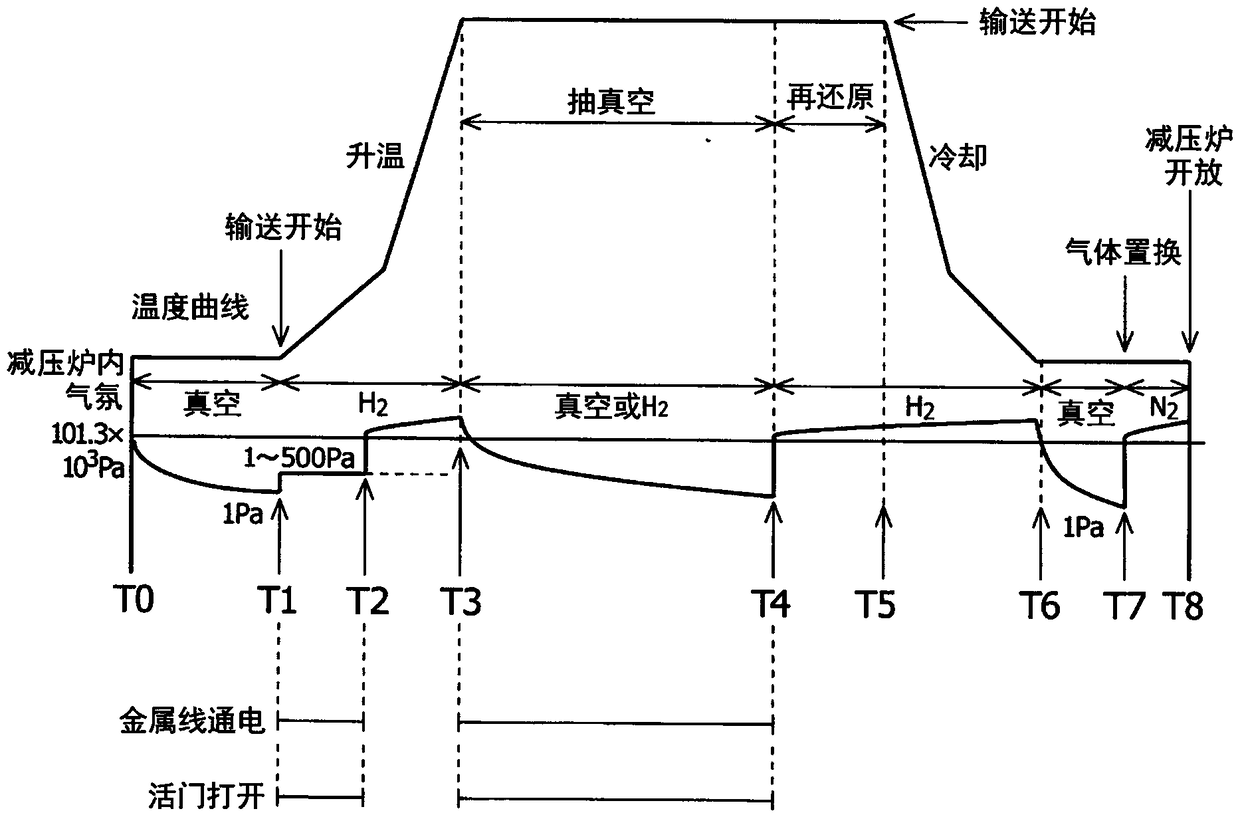

[0042] As a first embodiment of the present invention, a bonding and assembling apparatus suitably used in a method of manufacturing a semiconductor device including at least a heat ray heating step that can be opened and closed is described with reference to the drawings. The process of heating the metal wire outside the decompression furnace or in the decompression furnace with the partition wall.

[0043] figure 1 A schematic diagram of a joint assembly device according to an embodiment of the present invention is shown in . The bonding and assembling device mainly includes a conveying platform 13, a cooling plate 15, a hot plate 16, a reducing gas introduction pipe 17, and an inert gas introduction pipe 18 in the decompression furnace 11, and also has a The opening and closing part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com