Preparation method of solid polymer aluminum electrolytic capacitor resistant to high temperature of 150 DEG C

A technology of aluminum electrolytic capacitors and solid polymers, applied in the field of capacitors, can solve the problems of long-term operation of capacitors and poor high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

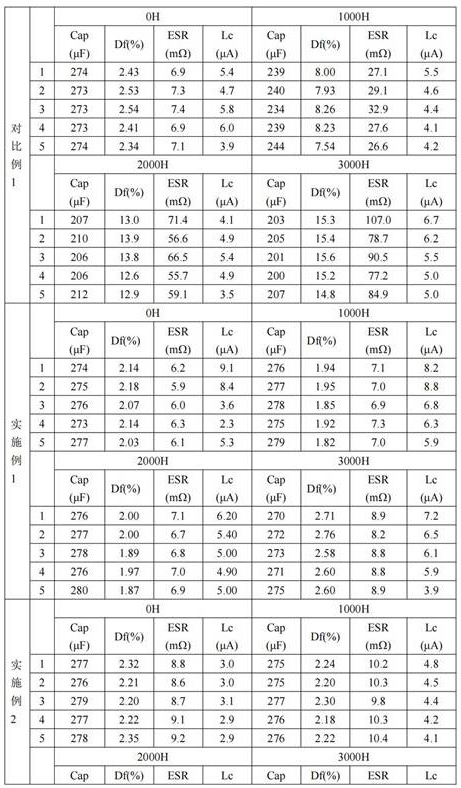

Embodiment 1

[0028] A preparation method of a solid polymer aluminum electrolytic capacitor resistant to high temperatures of 150°C:

[0029] Immersing the capacitor element with aluminum and the dielectric layer formed by the aluminum oxide film in the aqueous dispersion of conductive high molecular polymer, then taking it out, drying it, and operating it at least once, and then obtaining the capacitor element with the conductive high molecular layer; and then Immerse the capacitor element with the conductive polymer layer in the plant polyphenol aqueous solution, take it out, dry it, and operate it at least once to obtain a capacitor element with a self-polymerized protective film of plant polyphenol outside the conductive polymer layer; after assembly Prepared solid polymer aluminum electrolytic capacitor;

[0030] The specific preparation method of the 150°C high temperature resistant solid polymer aluminum electrolytic capacitor of this embodiment is as follows:

[0031] (1) Cut the ...

Embodiment 2

[0037] A preparation method of a solid polymer aluminum electrolytic capacitor resistant to high temperatures of 150°C:

[0038]Immersing the capacitor element with aluminum and the dielectric layer formed by the aluminum oxide film in the aqueous dispersion of conductive high molecular polymer, then taking it out, drying it, and operating it at least once, and then obtaining the capacitor element with the conductive high molecular layer; and then Immerse the capacitor element with the conductive polymer layer in the plant polyphenol aqueous solution, take it out, dry it, and operate it at least once to obtain a capacitor element with a self-polymerized protective film of plant polyphenol outside the conductive polymer layer; after assembly Prepared solid polymer aluminum electrolytic capacitor;

[0039] The specific preparation method of the 150°C high temperature resistant solid polymer aluminum electrolytic capacitor of this embodiment is as follows:

[0040] (1) Cut the p...

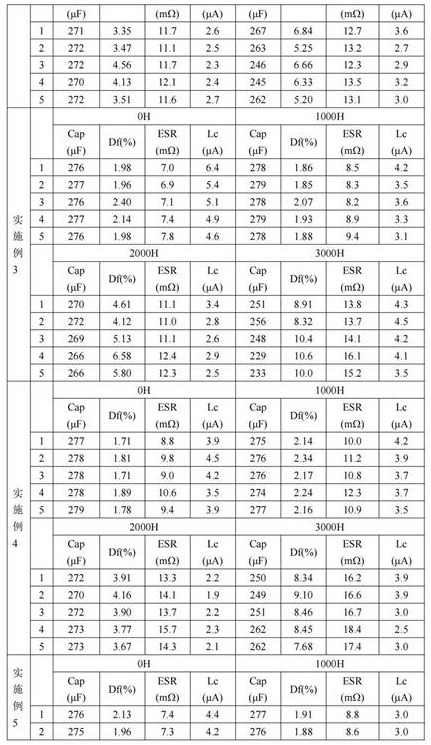

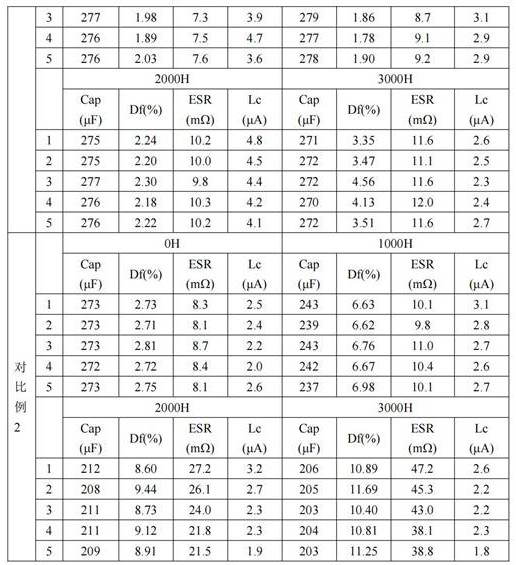

Embodiment 3

[0046] A preparation method of a solid polymer aluminum electrolytic capacitor resistant to high temperatures of 150°C:

[0047] Immersing the capacitor element with aluminum and the dielectric layer formed by the aluminum oxide film in the aqueous dispersion of conductive high molecular polymer, then taking it out, drying it, and operating it at least once, and then obtaining the capacitor element with the conductive high molecular layer; and then Immerse the capacitor element with the conductive polymer layer in the plant polyphenol aqueous solution, take it out, dry it, and operate it at least once to obtain a capacitor element with a self-polymerized protective film of plant polyphenol outside the conductive polymer layer; after assembly Prepared solid polymer aluminum electrolytic capacitor;

[0048] The specific preparation method of the 150°C high temperature resistant solid polymer aluminum electrolytic capacitor of this embodiment is as follows:

[0049] (1) Cut the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com