Vinyl alcohol polymer-containing coating agent for paper and paper and thermal paper coated with the coating agent

A technology of coating agent and vinyl alcohol, which is applied in the field of paper and thermal paper to achieve the effect of less yellowing and excellent water resistance

Active Publication Date: 2010-08-18

KURARAY CO LTD

View PDF4 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the combination of ethylene-modified PVA and a crosslinking agent disclosed in JP-A-9-66666 and JP-A-11-208115 does not necessarily provide sufficient water resistance.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Synthetic example 1

Synthetic example 2

Synthetic example 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

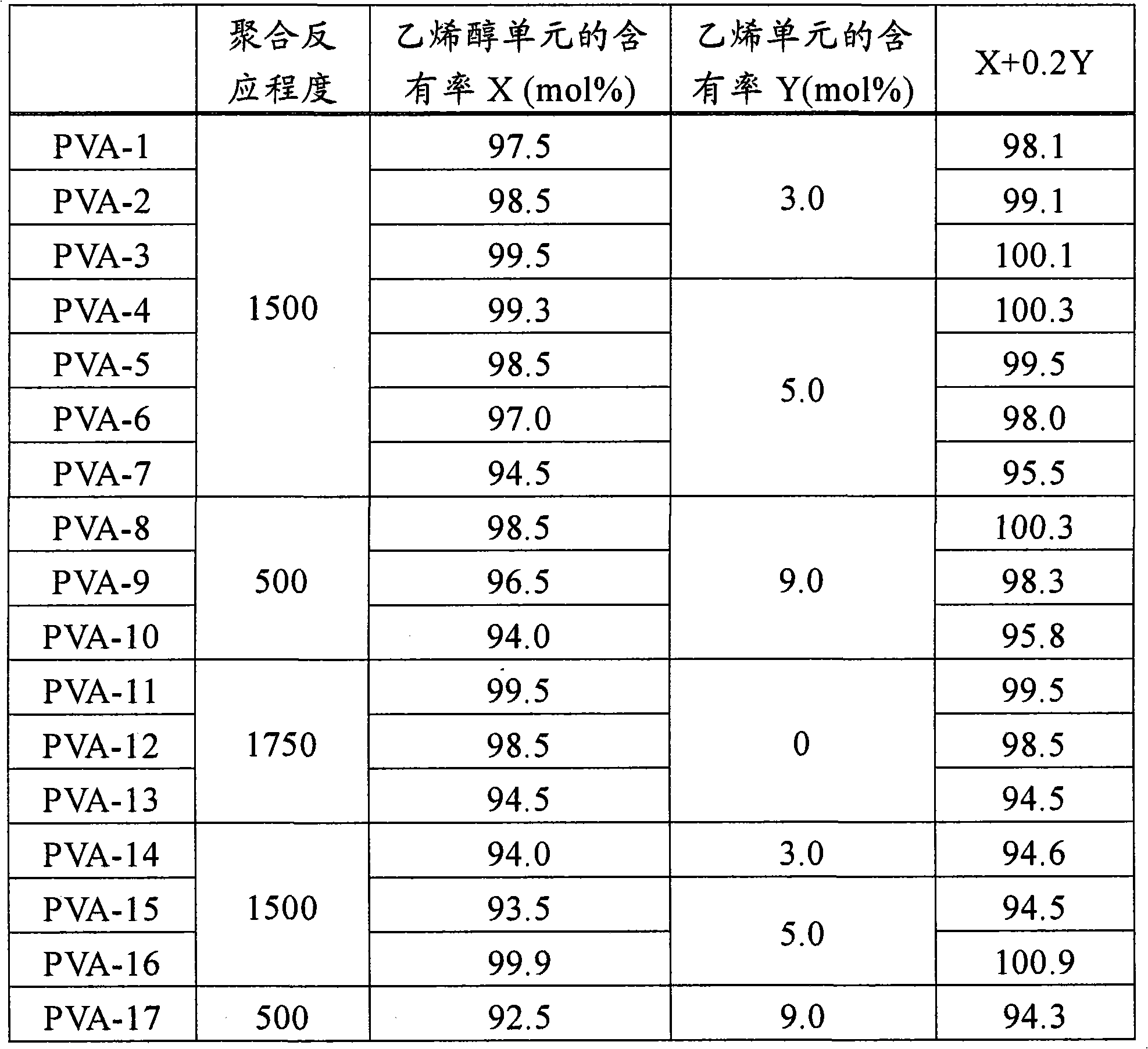

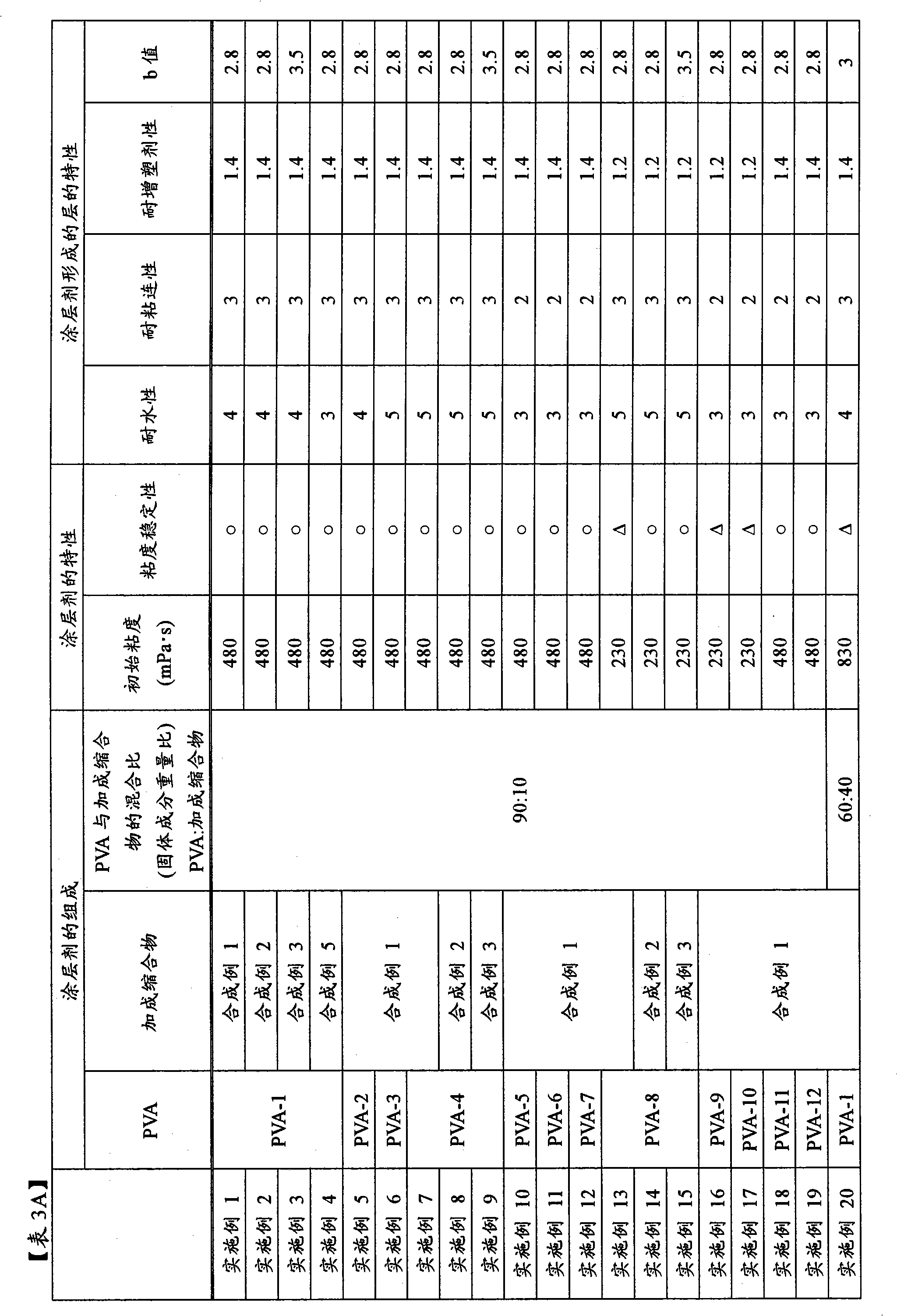

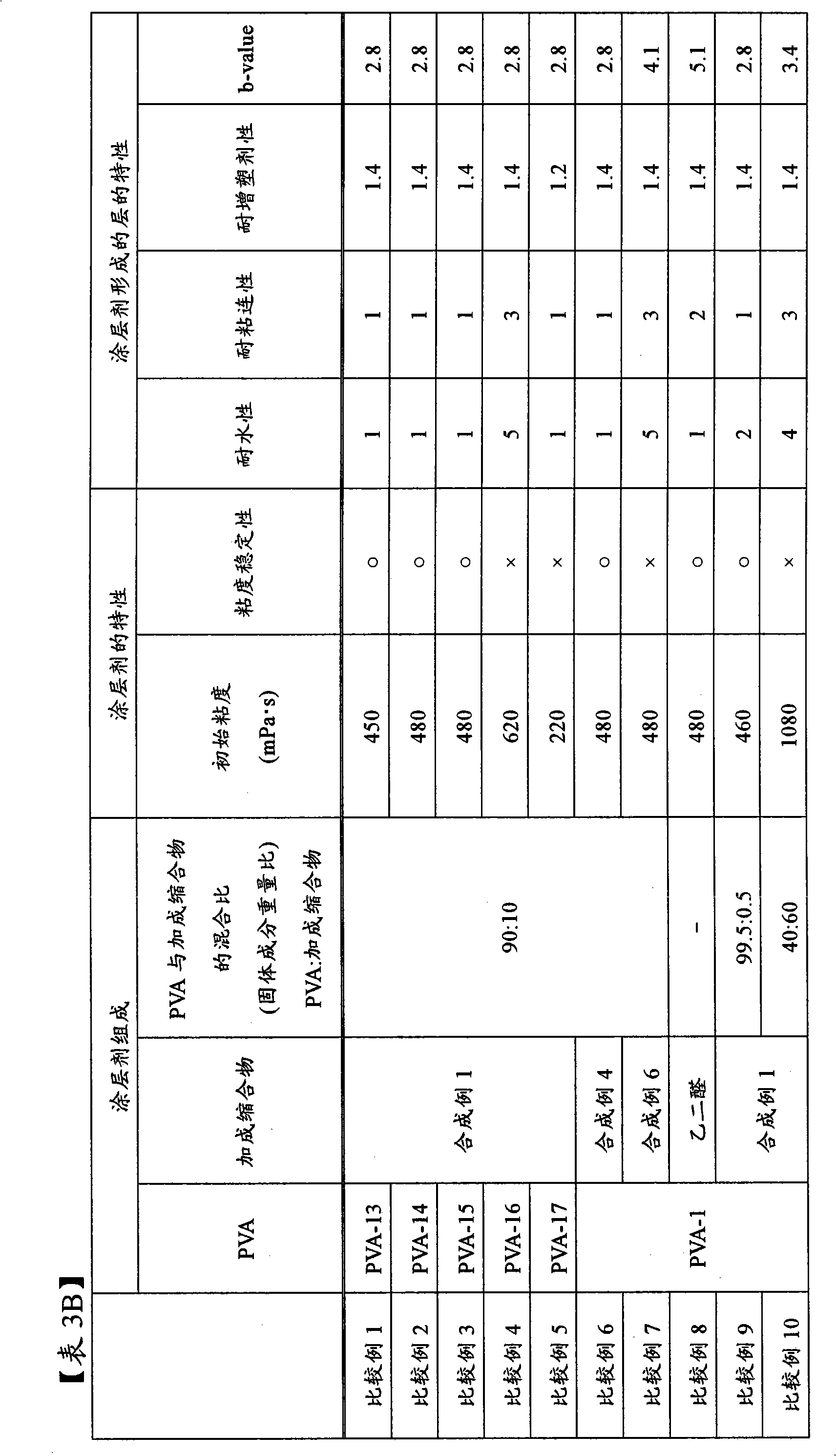

This invention provides a vinyl alcohol polymer-containing coating agent for paper, which, despite the fact that a curing step after coating the coating agent onto a paper surface can be omitted, can form a layer (for example, a coating layer or a color developing layer) having excellent water resistance and having no significant susceptibility to yellowing with the elapse of time. The coating agent is an aqueous composition comprising a vinyl alcohol polymer (A) satisfying a formula 'X + 0.2Y > 95', wherein X represents the content of vinyl alcohol units, % by mole; and Y represents the content of ethylene units, % by mole, and an addition condensation product (B) between ethylene urea and glyoxal. In the addition condensation product (B), the content of the terminal aldehyde group per g of the solid is 1.2 to 3.0 (mmol). The weight ratio on a solid basis between the vinyl alcohol polymer (A) and the addition condensation product (B) is in the range of (A) : (B) = 99 : 1 to 50 : 50. In the above formula, X < 99.9 and 0 <= Y < 10.

Description

technical field The present invention relates to a coating agent for paper containing a vinyl alcohol polymer, paper coated with the coating agent, and heat-sensitive paper. Background technique Vinyl alcohol polymers (hereinafter also simply referred to as "PVA") have unparalleled properties of other water-soluble resins in terms of film formation and adhesiveness (such as bond strength), so they are widely used as various adhesives, adhesives, etc. Bonding agent or surface treatment agent, etc. One of the uses of PVA is a coating agent for paper for the purpose of improving the surface strength of paper, and the paper coated with PVA on the paper surface can be used, for example, as printing paper. In addition, PVA includes modified polyvinyl alcohol having constituent units other than vinyl alcohol units, such as ethylene units. There are various types of paper printing methods, but offset printing is currently the mainstream. Offset printing is to form a non-image pa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D21H19/20B41M5/337C08G12/36D21H19/24

CPCB41M5/3372D21H19/20B41M5/5254D21H19/24B41M5/44Y10T428/31895

Inventor 直原敦仲前昌人中川和城堀公二渡边美纱

Owner KURARAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com