Vertical continuous microwave heating low-temperature cracking furnace for garbage

A low-temperature cracking and microwave heating technology, used in coke ovens, special forms of dry distillation, petroleum industry, etc., can solve the problems of unrealizable cracking environment, insignificant recovery benefits, and high reducing atmosphere conditions, and achieve continuous and reliable oxygen replacement. , Guarantee stability and reliability, and ensure the effect of system air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

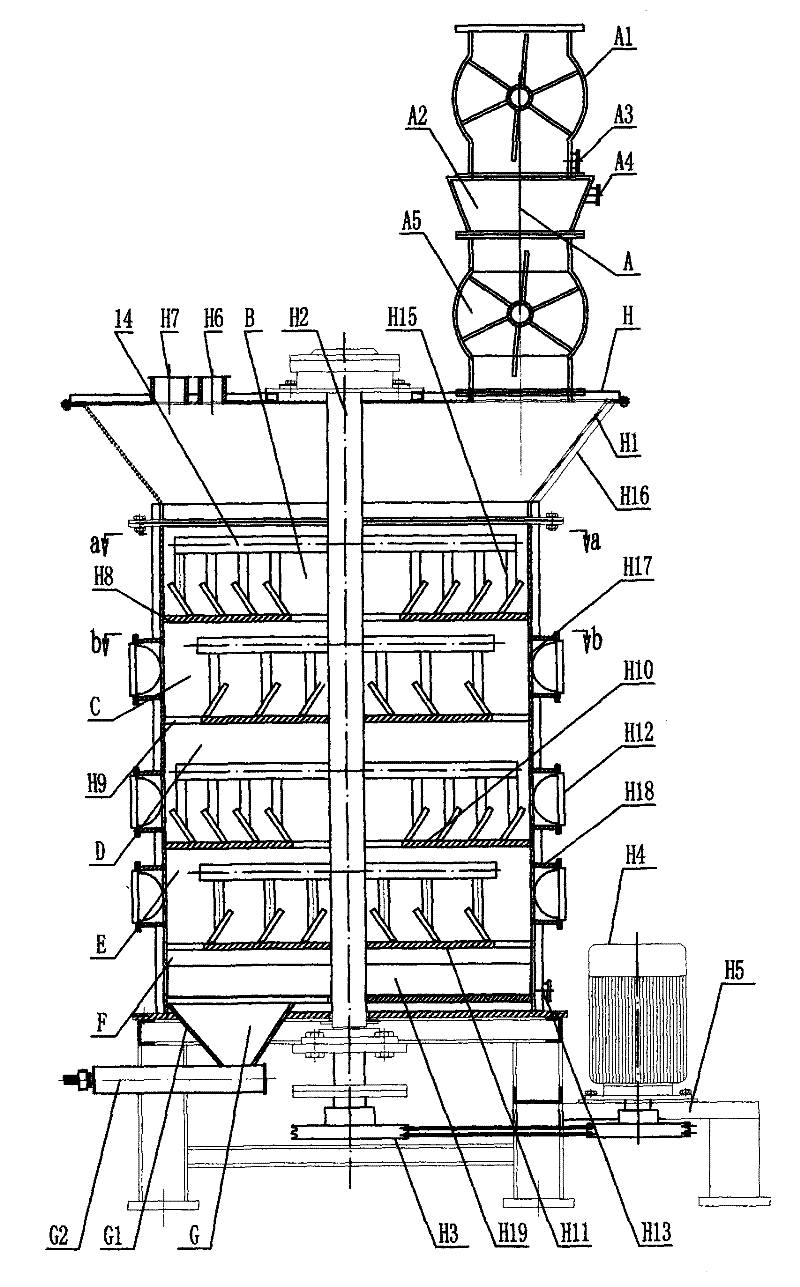

[0050]Referring to the accompanying drawings, a vertical continuous microwave heating low-temperature pyrolysis furnace is composed of: feeding and waste gas replacement mechanism A, waste preheating and pyrolysis steam output bin B, waste moisture evaporation and heating bin C, waste main The pyrolysis bin D, the cracking material carbonization bin E, the carbonized material collection bin F, the carbonized material collection mechanism G and the host body part H are composed.

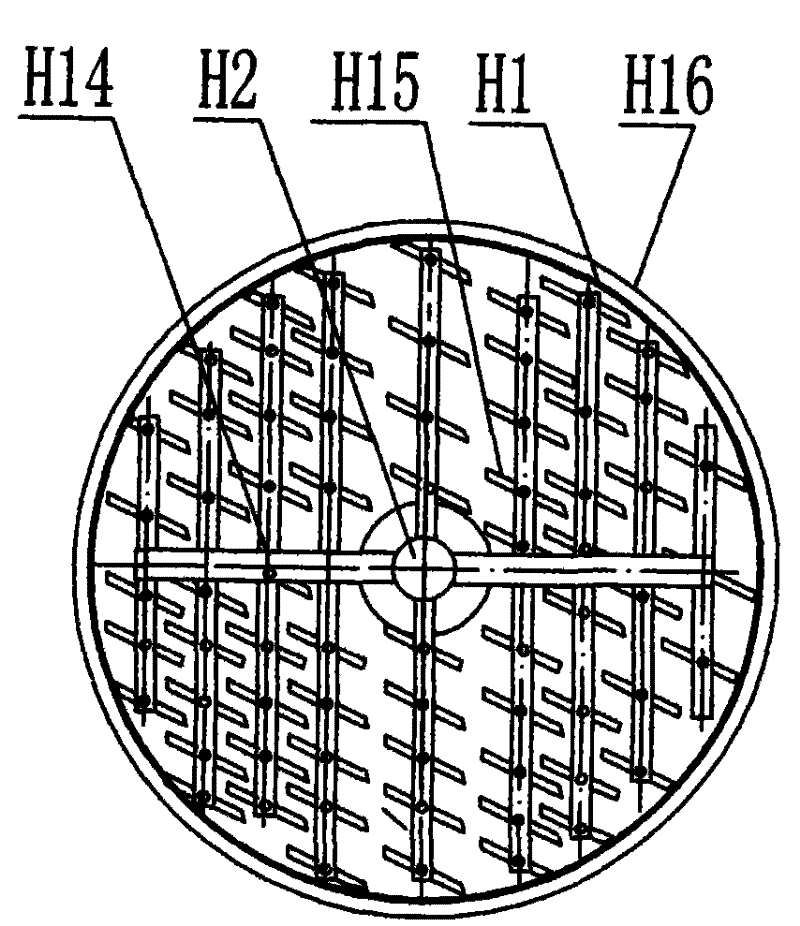

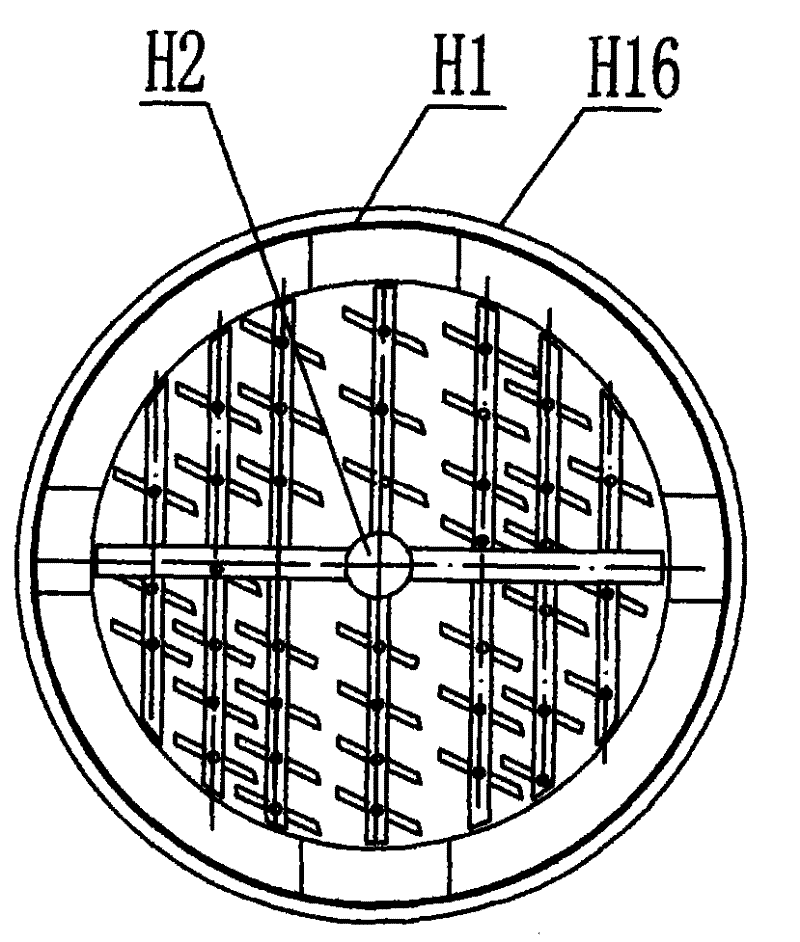

[0051] The host body part H includes: a host cylinder H1, a power spindle H2, a spindle power wheel H3, a spindle power motor H4 and a frame H5, and the upper end of the host cylinder H1 is a circular cylinder with a tapered feeding port The upper and lower ends of the main cylinder H1 are sealed structures. The power spindle H2 is supported by bearings and set in the center of the main cylinder H1. The power spindle H2 forms a transmission connection with the main shaft power motor H4 through the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com