Preparation method of low-arsenicred iron oxide pigment

A technology of iron oxide red and pigments, which is applied in the field of preparation of low-arsenic iron oxide red pigments, can solve the problems that the content cannot be effectively controlled, the product performance is not ideal, the consumption of iron non-renewable resources, etc., and achieve good color covering power, particle size Exquisite and delicate, the effect of saving iron resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

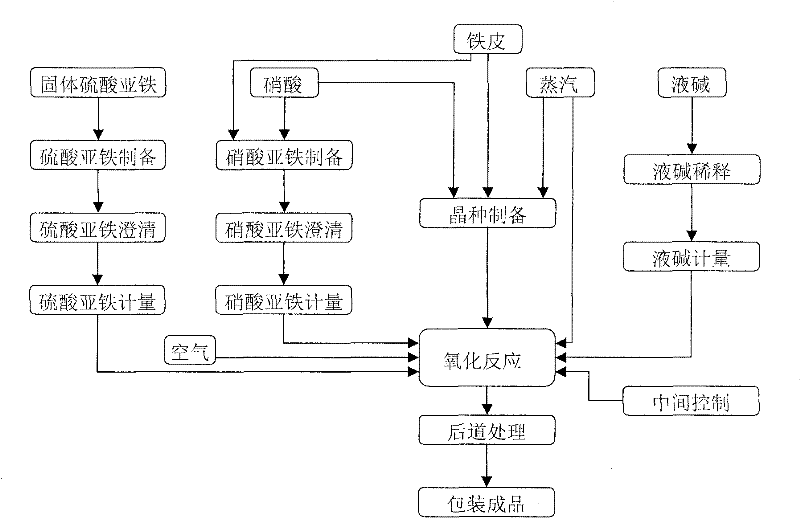

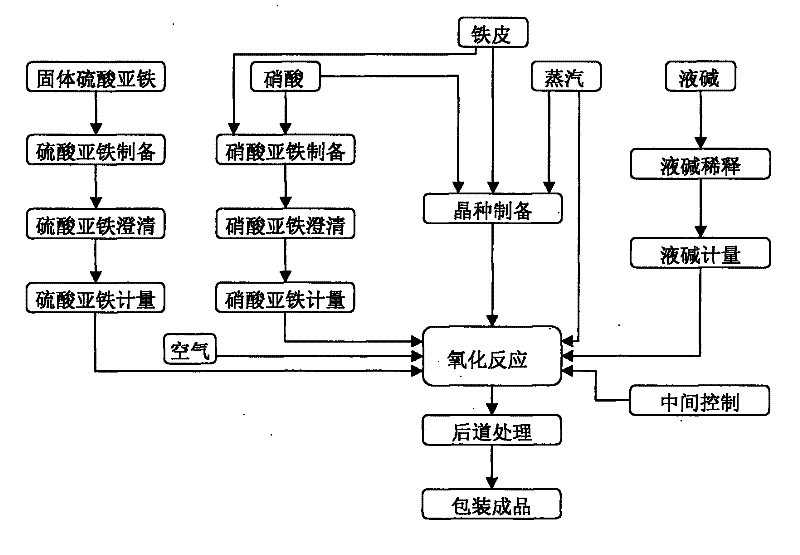

[0033] like figure 1 The production method of described iron oxide red pigment as shown comprises seed crystal preparation and two-step oxidation, and process step is as follows:

[0034] i) seed crystal preparation,

[0035] a) Put 650Kg low-arsenic iron sheet into the high-pressure barrel, and add appropriate amount of water;

[0036] b) warming up to 70°C and injecting 1000kg parts by weight of dilute nitric acid with a content of 40%;

[0037] c) React at a pressure of 0.35Mpa, keep the pressure for 15min, open the vent valve, drop to a pressure of 0.1-0.2Mpa, and transport it to the seed storage tank.

[0038] ii) Ferrous nitrate preparation part

[0039] d) Put the iron sheet in a long reaction tank, and react with dilute nitric acid at a long temperature (≤60° C.) to generate ferrous nitrate and ammonium nitrate. The concentration after the reaction is 10.8%, and the pH value is 3.0.

[0040] iv) ferrous sulfate preparation part

[0041] e) dissolving the solid fer...

Embodiment 2

[0047] like figure 1 As shown, the production method of the iron oxide red pigment includes seed crystal preparation and two-step oxidation, and the process steps are as follows:

[0048] i) Seed crystal preparation

[0049]a) Put 680Kg low-arsenic iron sheet into the high-pressure barrel, and add appropriate amount of water;

[0050] b) warming to 70°C and injecting 1250kg parts by weight of dilute nitric acid with a content of 40%;

[0051] c) React at a pressure of 0.40Mpa, keep the pressure for 15min, open the vent valve, drop to a pressure of 0.1-0.2Mpa, and transport to the seed storage tank.

[0052] ii) Ferrous nitrate preparation part

[0053] d) Put the iron sheet in a long reaction tank, and react with dilute nitric acid at a long temperature (≤60° C.) to generate ferrous nitrate and ammonium nitrate. The concentration after the reaction is 11.7%, and the pH value is 3.2.

[0054] iv) ferrous sulfate preparation part

[0055] E) be that the solid ferrous sulfat...

Embodiment 3

[0062] like figure 1 As shown, the production method of the iron oxide red pigment includes seed crystal preparation and two-step oxidation, and the process steps are as follows:

[0063] i) seed crystal preparation,

[0064] a) Put 750Kg low-arsenic iron sheet into the high-pressure barrel, and add appropriate amount of water;

[0065] b) flushing temperature to 70 ℃ and injecting 1380kg parts by weight of dilute nitric acid with a content of 40%'

[0066] c) React at a pressure of 0.45Mpa, keep the pressure for 15min, open the vent valve, drop to a pressure of 0.1-0.2Mpa, and transport to the seed storage tank.

[0067] ii) Ferrous nitrate preparation part

[0068] d) Put the iron sheet in a long reaction tank, and react with dilute nitric acid at a long temperature (≤60° C.) to generate ferrous nitrate and ammonium nitrate. The concentration after the reaction is 13.5%, and the pH value is 3.6.

[0069] iv) ferrous sulfate preparation part

[0070] e) dissolving the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com