Technology and device for recovering ammonia from garbage leachate in domestic garbage sanitary landfill site

A technology for landfill leachate and domestic waste, which is applied in the recovery process and equipment field of waste leachate ammonia in sanitary landfills of domestic waste. It can solve the problems of high equipment cost, frequent equipment maintenance, pipeline blockage, etc., and achieve cost reduction. , Improve water environment quality and reduce discharge

Active Publication Date: 2010-08-25

武汉循环经济研究院 +3

View PDF0 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In particular, it solves the equipment problem of reaction between ammonia-containing gas and sulfuric acid after deamination, overcomes the problems of high cost of ammonium sulfate saturator process equipment, easy blockage of pipelines by ammonium sulfate crystals, frequent equipment maintenance and other problems, high absorption efficiency, and simple operation and management.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

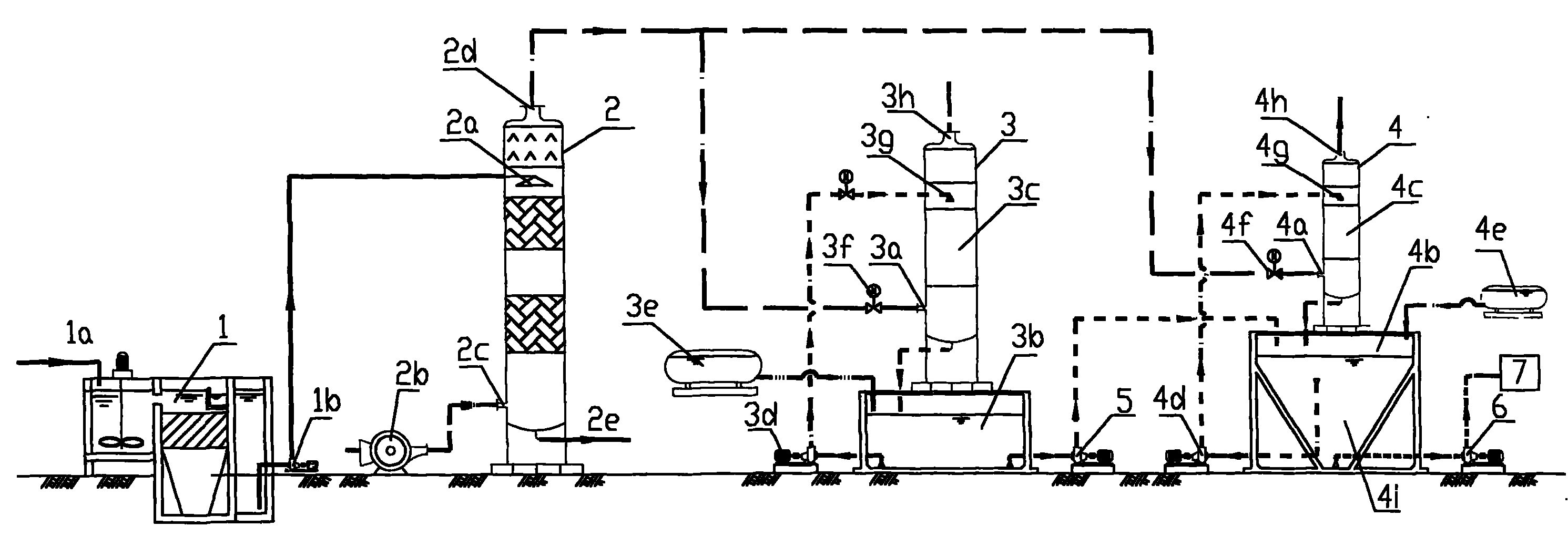

The invention provides a technology and device for recovering ammonia from garbage leachate in a domestic garbage sanitary landfill site. The method comprises the following steps: (1) removal of ammonia in garbage leachate: adding alkaline chemicals into the leachate to regulate the pH value of the garbage leachate to 9-11, and removing ammonia in the garbage leachate in an ammonia removal tower by using an air stripping method; (2) ammonia recovery: recovering ammonia sulfate from gas containing ammonia by using a sulfuric acid solution absorption method, wherein the absorption is realized by two absorption reactors: in the first absorption reactor, 85-95% of gas containing ammonia is processed, and the concentration of ammonia sulfate in the circulating mother liquor in the first absorption reactor is lower than the saturation concentration of ammonia sulfate, thereby preventing ammonia sulfate from crystallizing; and the unsaturated circulating mother liquor in the first absorption reactor is sent into a second absorption reactor to continuously react with 5-15% of gas containing ammonia, so that the concentration of ammonia sulfate in the circulating mother liquor in the second absorption reactor is higher than the saturation concentration of ammonia sulfate, thereby promoting the ammonia sulfate to crystallize; and (3) separating ammonia sulfate crystals.

Description

Recovery process and equipment for ammonia leachate in sanitary landfill of domestic waste technical field The invention relates to a recovery process and equipment for ammonia leachate in domestic waste sanitary landfills, and in particular to the technical field of domestic waste treatment and utilization. Background technique Sanitary landfill is a method of disposing solid waste widely used in my country in recent years. For an anaerobic landfill, its mechanism is to use anaerobic fermentation method to convert organic matter in garbage into gaseous products such as carbon dioxide and methane through the degradation of anaerobic and facultative microorganisms. Since municipal solid waste itself contains a lot of water, it will leach out in the form of leachate during the bioconversion process. At the same time, affected by factors such as rainfall and runoff, landfills will also pass through percolation to form landfill leachate. The composition of landfill leachate...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F1/20C01C1/10

Inventor 李武梁顺文黄凯兴李育杰徐殿广陈石孟了王克虹冯向明李智勤顾飞孙志军

Owner 武汉循环经济研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com