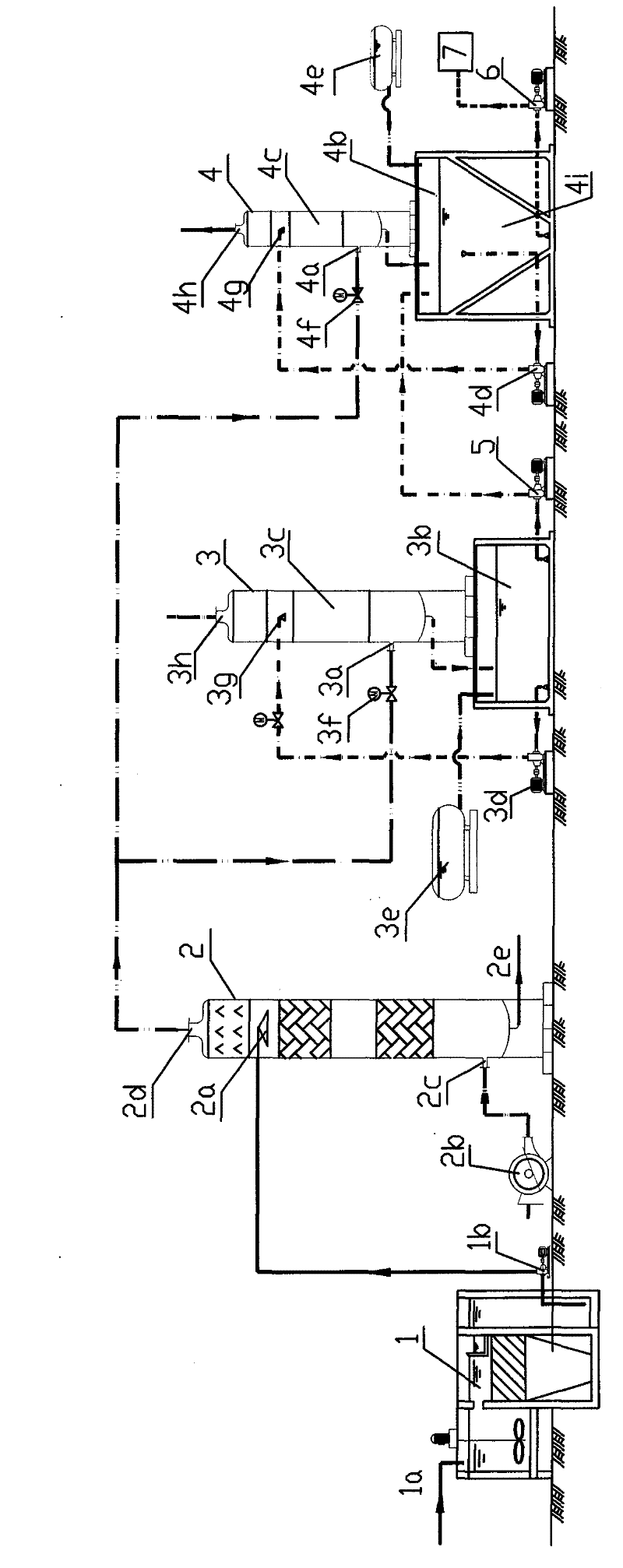

Recovery process and equipment for ammonia leachate in sanitary landfill of domestic waste

A technology for landfill leachate and domestic waste, which is applied in the recovery process and equipment field of waste leachate ammonia in sanitary landfills of domestic waste. It can solve the problems of high equipment cost, frequent equipment maintenance, and pipeline blockage, so as to reduce emissions. The effect of improving the water quality, improving the quality of water environment, and improving the living conditions of residents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

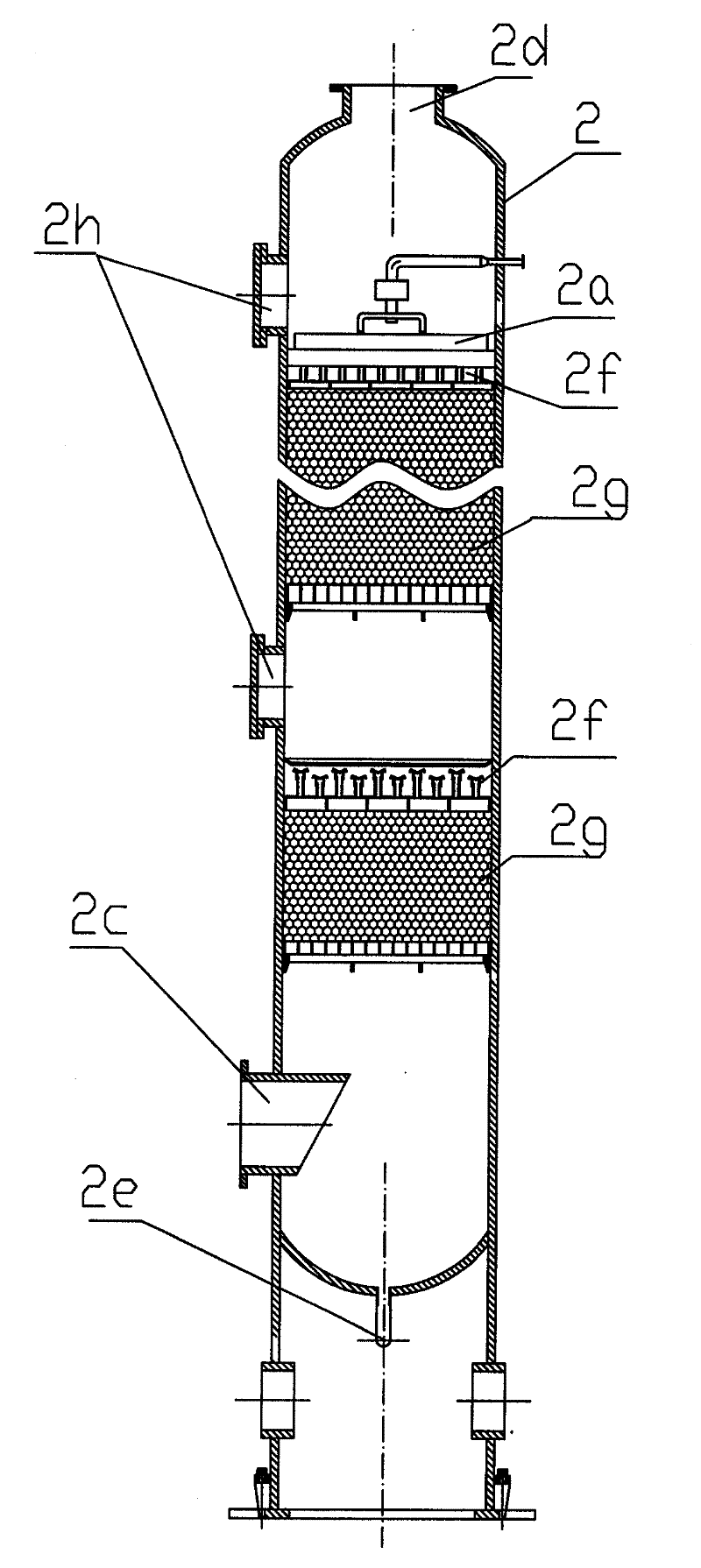

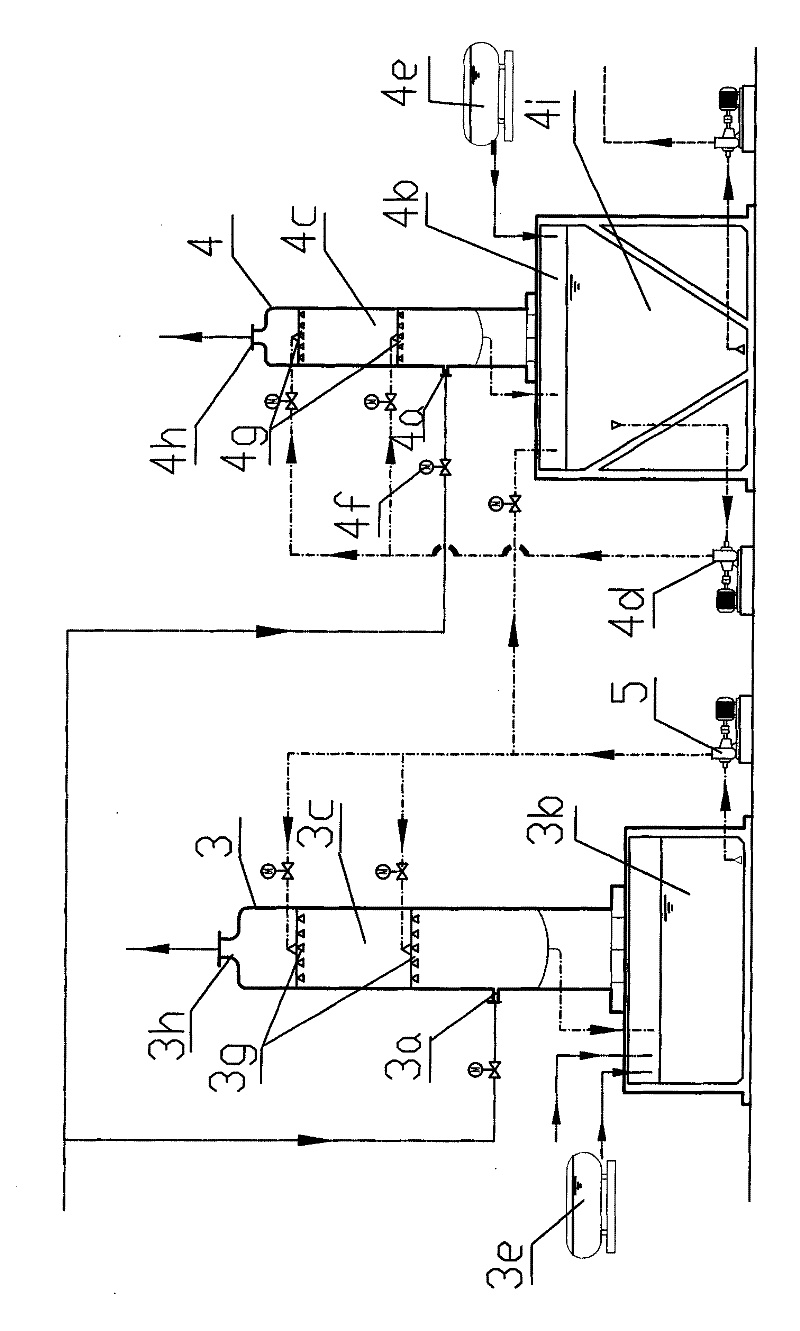

Method used

Image

Examples

Embodiment Construction

[0042] The removal principle of ammonia in the leachate of domestic garbage sanitary landfill:

[0043] Ammonia in landfill leachate is generally expressed as ammonium ion (NH 4 + ) and free ammonia (NH 3 ) form, and maintain the following ionization balance in water:

[0044] (1)

[0045] This balance is affected by pH. When the pH value increases, the balance shifts to the right and free ammonia increases; when the pH value decreases, the balance shifts to the left and the ammonium ions increase. When the pH of the water rises to about 11, the ammonia in the water is almost all in the form of NH 3 Exists in the form of ammonia, if it is stirred, aerated, etc., it can promote the transfer of ammonia from the water to the atmosphere.

[0046] Absorption principle of ammonia-containing gas in leachate of sanitary landfill of domestic waste:

[0047] Sulfuric acid absorbs ammonia in ammonia-containing gas to obtain ammonium sulfate, and its chemical reaction formula is:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com