Reactive dye for dyeing nylon and preparation method thereof

A dye, nylon technology, applied in the field of reactive navy blue dye and its preparation, can solve the problems of human skin damage, poor fastness, not bright color and light, etc., and achieve the effect of eliminating pollution, reducing usage, and bright color.

Active Publication Date: 2010-08-25

TIANJIN DEK CHEM

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Because the fabrics dyed by weak acid dyes have poor fastness and not bright shade, especially the pollution of heavy metals in the manufacturing process of metal complex dyes and the pollution during dyeing, and the damage of dyed nylon fabrics to human skin

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

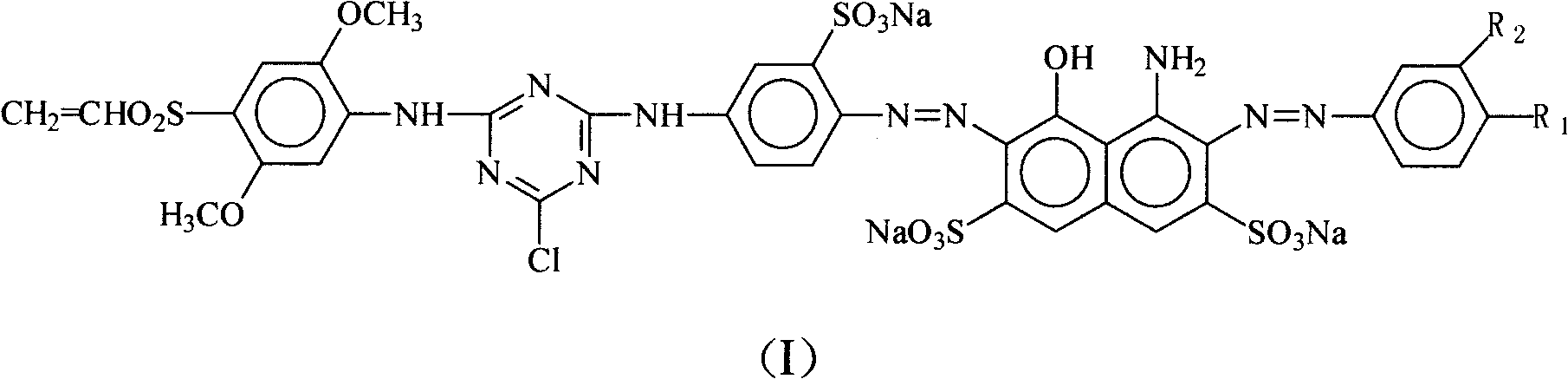

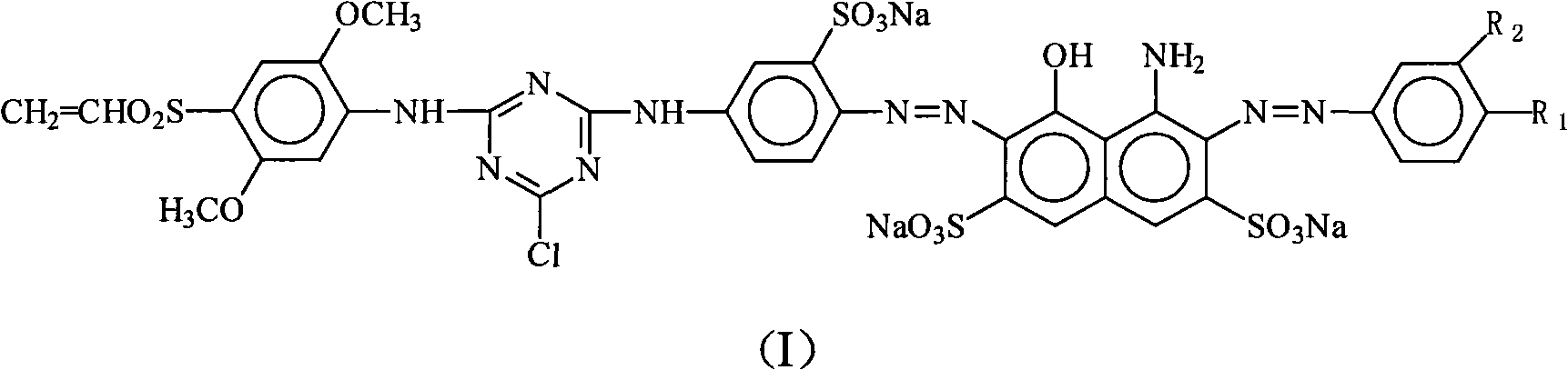

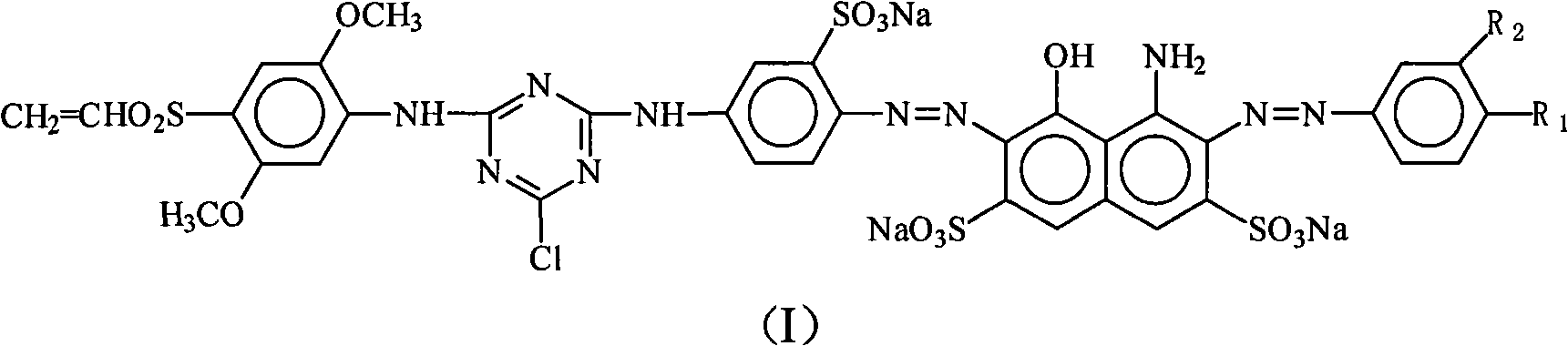

The invention relates to a reactive dye for dyeing nylon and a preparation method thereof. The dye has the following structural formula (I). The preparation method for the dye comprises the following steps: (a) adding hydrochloric acid solution and sodium nitrite solution into meta-nitroaniline or p-nitroaniline; (b) dripping H acid into the solution of the step (a); (c) dissolving 2,5-dimethoxy meta-ester into water; (d) adding the solution obtained in the step (c) into cyanuric chloride suspension to perform reaction, and adding 2,5-diaminophenylsulfonic acid into the solution after the reaction is finished; (e) adding the hydrochloric acid solution into the solution of the step (d), and then adding sodium nitrite solution into the solution; (f) dripping the solution of the step (e) into the solution of the step (b); and (g) converting beta-ethyl sulfone sulfate of the coupling solution of the step (f) into vinyl sulfone under the alkali condition so as to form a compound of the structural formula (I).

Description

technical field The invention relates to a dye and a preparation method thereof, in particular to a reactive navy blue dye and a preparation method thereof. Background technique The dyes generally used in the dyeing of nylon fabrics are weak acid dyes and metal complex dyes. The fabrics dyed by weak acid dyes have poor fastness and not bright shade, especially the pollution of heavy metals in the manufacturing process of metal complex dyes and the pollution during dyeing, as well as the damage of dyed nylon fabrics to human skin. Due to environmental and ecological constraints, the requirements for dyeing rate, color fixing rate and dyeing wastewater are getting higher and higher. The development of navy blue reactive nylon dyes has always been a hot spot in the dye industry, because navy blue is the most used in all shades and is the main component of black spelling. The invention provides a reactive navy blue dye suitable for nylon dyeing, which solves the technical prob...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09B62/513C07D251/50D06P3/28

Inventor 张兴华李荣才

Owner TIANJIN DEK CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com