Polygonal plastic bag swing cell reactor and method for culturing animal cells

A technology of cell reactors and animal cells, applied in tissue cell/virus culture devices, biochemical equipment and methods, biochemical instruments, etc., can solve the limitations of the versatility and convenience of the reactor, the inability of the reactor to move, and the damage to animals Cells and other problems, to achieve the effect of solving mechanical damage, easy quality assurance, and not easy to be polluted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

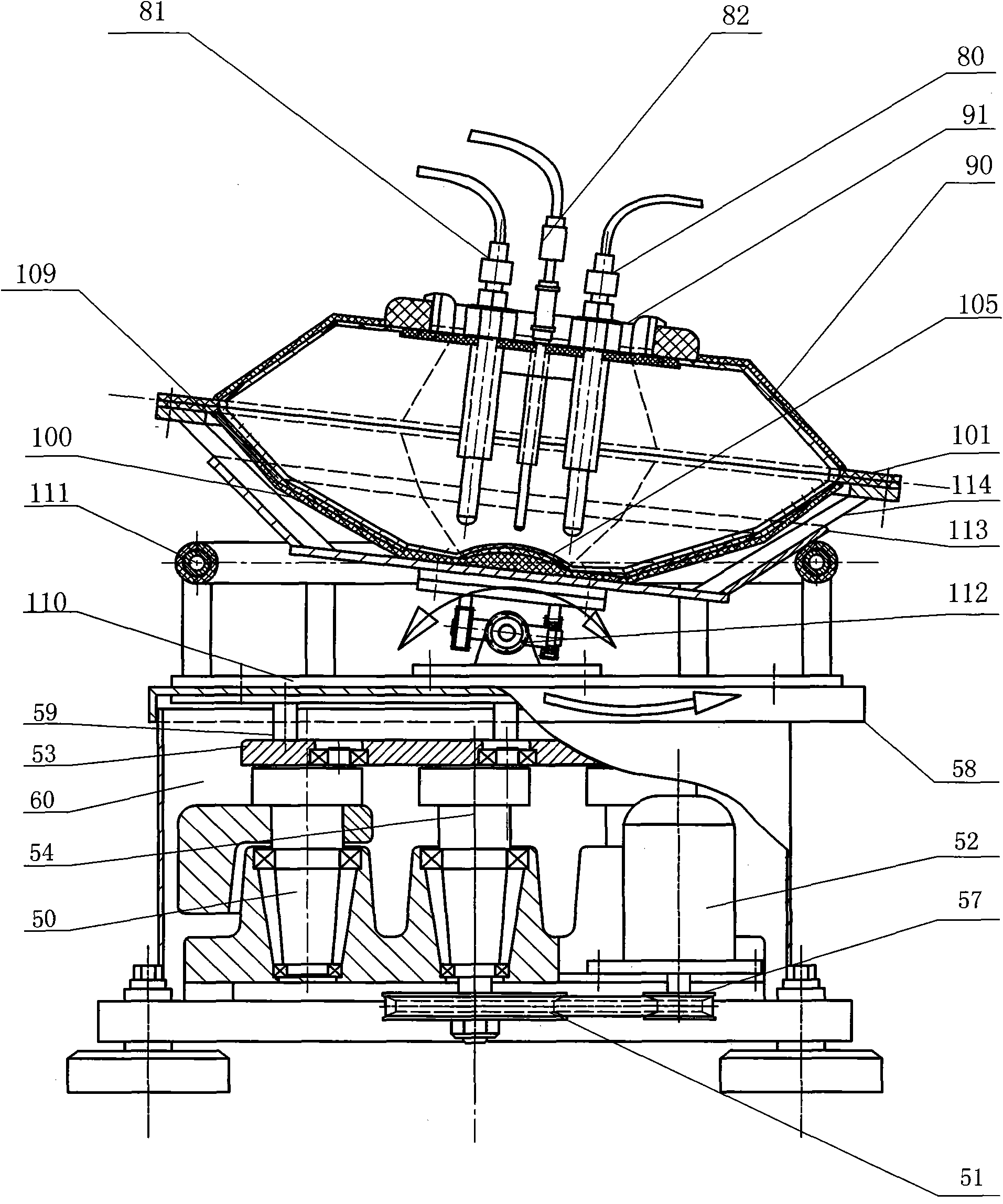

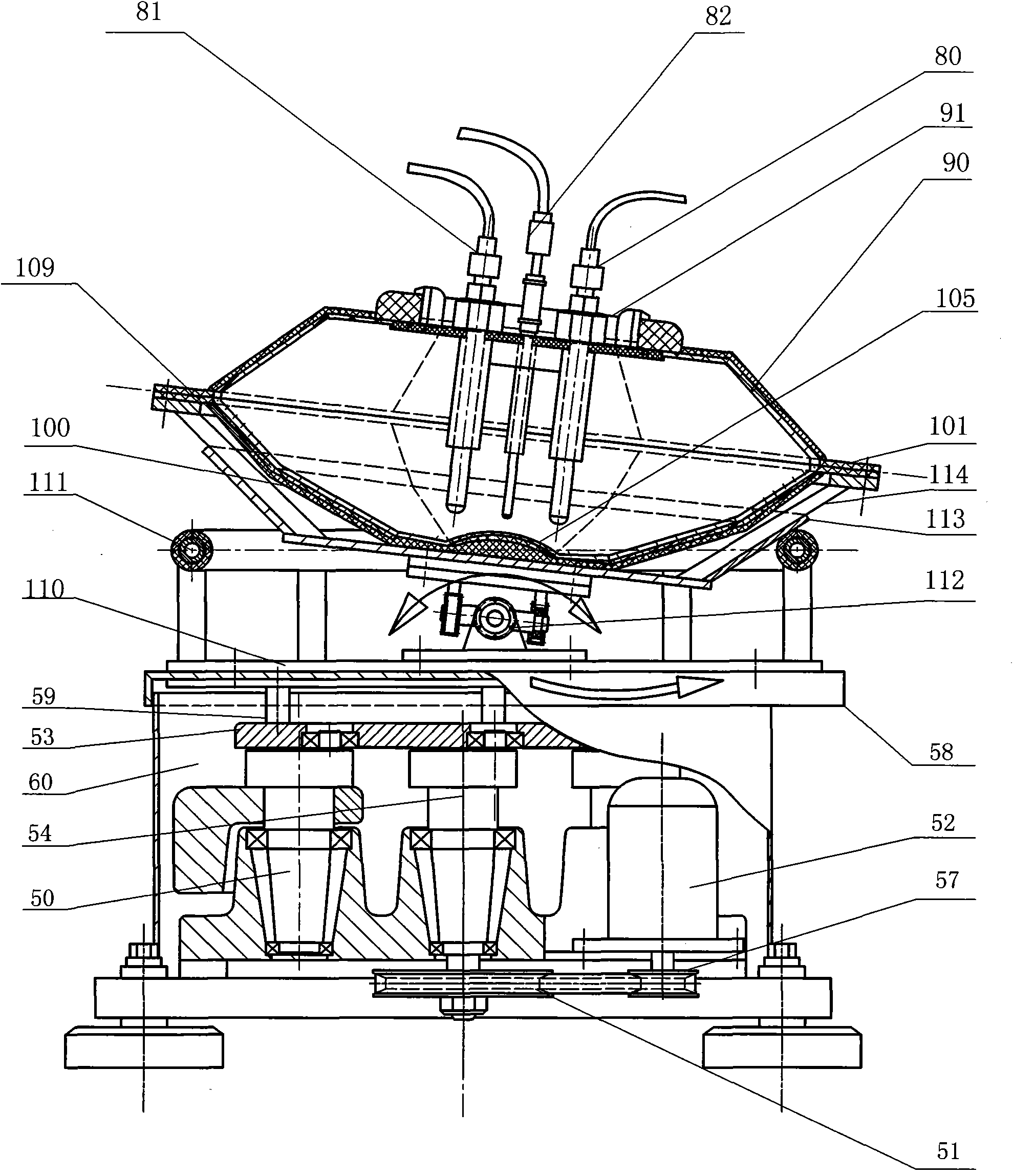

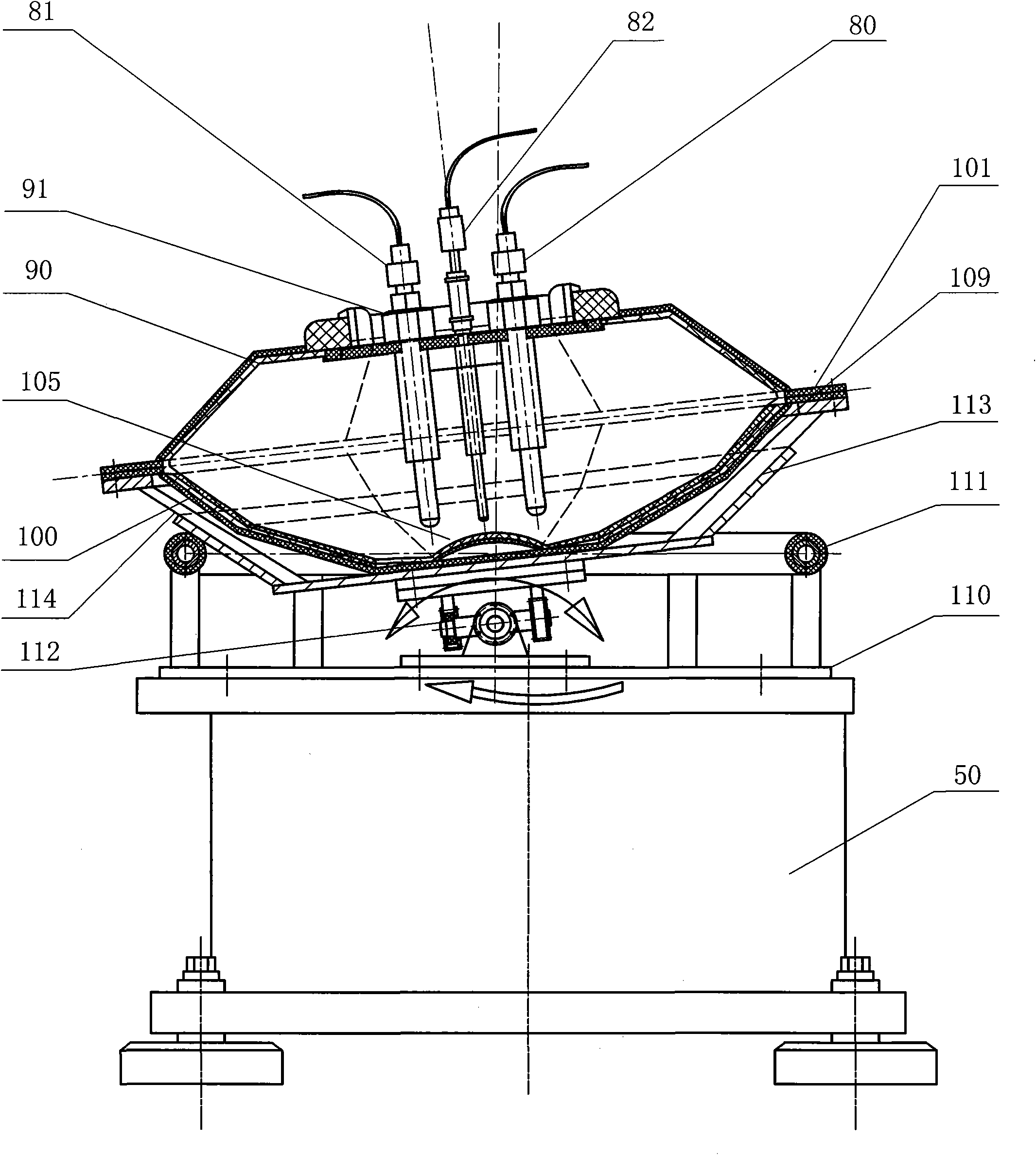

[0027] Polygonal plastic bag rocking cell reactor, its composition comprises: shaker 60, described rocker is connected with rocking mechanism, and polygonal reaction tank 100 is installed inside described rocking mechanism, and polygonal plastic culture bag is housed in described polygonal reaction tank 90, the polygonal plastic culture bag has a plastic multi-function disc 91 on it, the temperature probe 82, the pH probe 81 and the dissolved oxygen probe 80 are respectively installed on the multi-function disc and penetrated into the polygonal plastic culture bag Inside, the multifunctional tray has an air inlet 86 , an air outlet 83 and a feed inlet 88 , and the bottom of the polygonal reaction tank has a distribution cone 105 . The distribution cone is used to prevent cell death caused by the accumulation of cells on the bottom of the reaction tank during rocking.

Embodiment 2

[0029] In the polygonal plastic bag swinging cell reactor described above, the polygonal reaction tank includes a lower tank body and an upper cover 101, and the lower tank body and the upper cover are connected by a connection method 106 blue, and the lower tank body There is a rubber heating plate 109 on the inner wall, and the upper cover has an upper cover opening 108, and the polygonal plastic culture bag is connected with the upper cover opening through a disc clamp 96 on its multi-functional tray.

Embodiment 3

[0031] In the polygonal plastic bag swing cell reactor described above, the swing mechanism includes a base 110, the base is connected with a cross shaft mechanism 112, and the cross shaft mechanism is connected with a swing basket 114, and the swing basket has an outer cone The plate 113 is connected with the buffer retaining ring 111 on the base. During the rocking process, the outer cone plate is supported by the buffer retaining ring, which has the function of shock absorption, reduces shock and vibration, and makes the rocking motion stable and reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com