Production method of superfine polypropylene composite fully-drawn wallpaper fiber

A production method, polypropylene technology, applied in fiber processing, stretch spinning, fiber cutting, etc., can solve the problems of not being able to meet the requirements of wall covering materials, easy to expose the wall surface, and cannot be bonded, and achieve excellent softness and elasticity Recoverability, excellent air conduction performance, and the effect of overcoming rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

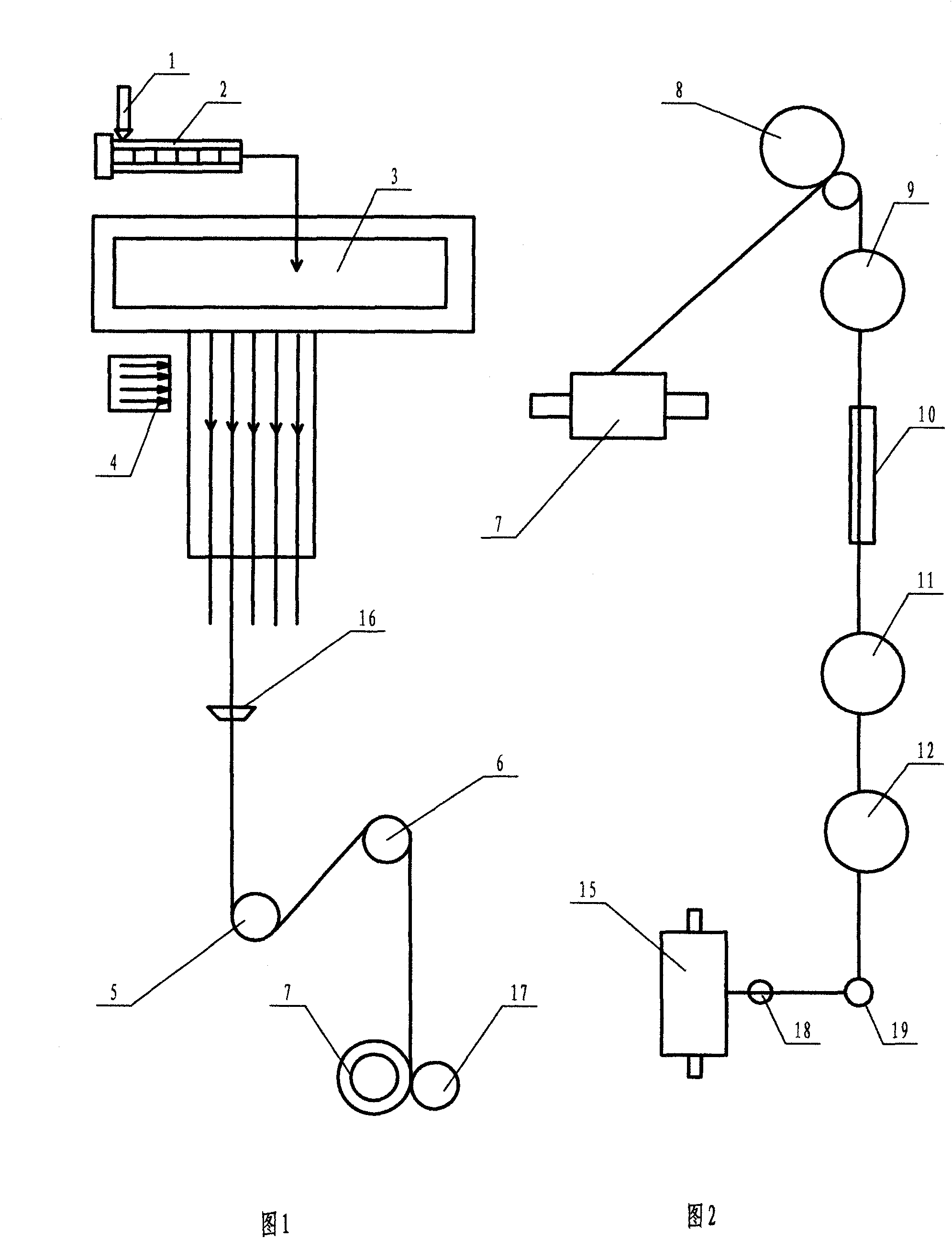

[0018] An embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

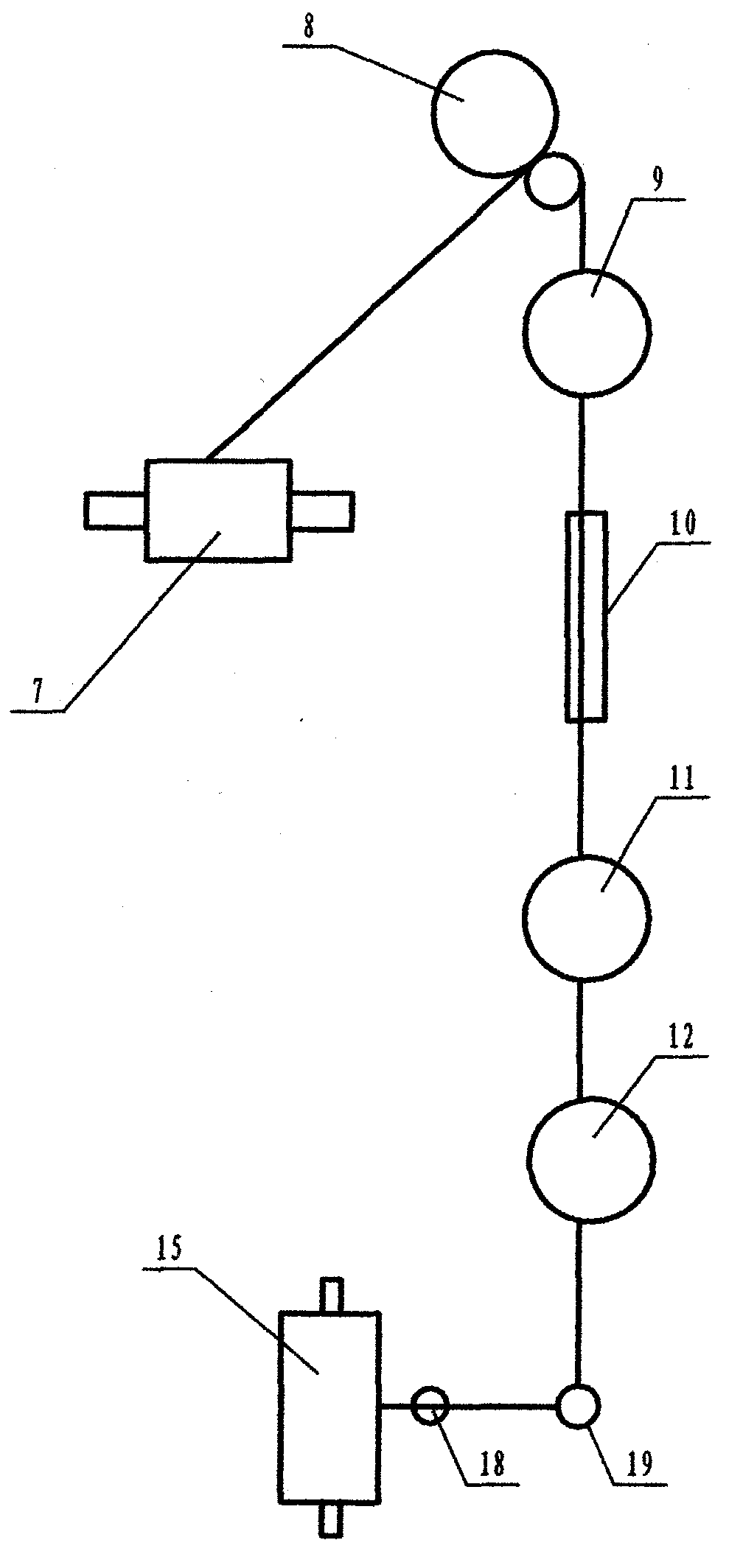

[0019] Adopt the spinning process flow shown in Figure 1, the first step of spinning: the polypropylene particles with a melt index of 2-4g / 10min enter the feed port 1 on the screw extruder 2 by their own weight from the feed hopper, Screw pressure is 80kgf / cm 2 , due to the rotation of the screw, the polypropylene particles move forward along the screw groove, and a heating element is installed on the outer periphery of the screw sleeve; the heating temperature of the screw extruder 2 where the polypropylene particles are located from the feeding section to the discharging section is: 1 Zone (feed section) 240°C, Zone 2 280°C, Zone 3 280°C, Zone 4 280°C, Zone 5 285°C, Zone 6 285°C, Elbow 280°C, Flange 280°C; heat transfer through the sleeve For polypropylene particles, the polypropylene particles are heated and melted and then compressed and extruded by the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com