Environment friendly light-weight composite keel plate

An environmentally friendly, keel plate technology, applied in the field of building decoration materials, can solve the problems of flammability, poor stability and easy deformation of steel keels, and achieve the effects of good anti-vibration performance, low cost and low shrinkage rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

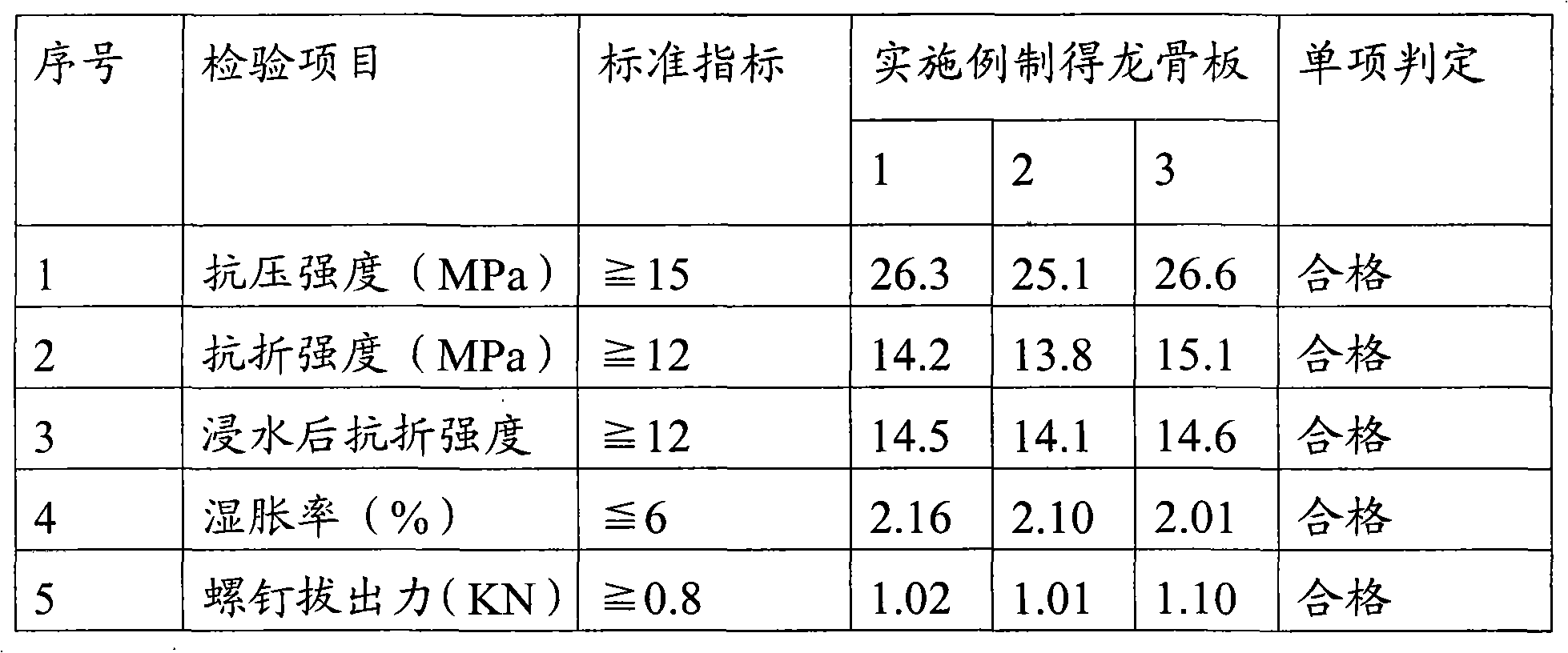

Embodiment 1

[0022] The environment-friendly light-body composite keel board described in this embodiment includes an intermediate base layer and a surface composite layer bonded on both sides of the intermediate base layer. The surface composite layer is composed of several surface material layers and glass fiber cloth layers alternately Composite, wherein the innermost glass fiber cloth layer of the surface composite layer is bonded to the intermediate base layer, and the outermost layer of the surface composite layer is a surface material layer; wherein

[0023] Surface material preparation: Including the following raw materials: 8kg of magnesium oxide, 0.5kg of wood chips or straw powder and 0.5kg of HHD agent. After mixing the above raw materials, dry stirring for 5-10min, then adding 5kg of FHL solution, and stirring again for 15-25min. The uniformity of the fine material reaches saturation; at this time, the sawdust absorbs the FHL solution to a saturated and stable state, and it will n...

Embodiment 2

[0035] The environment-friendly light-body composite keel board described in this embodiment includes an intermediate base layer and a surface composite layer bonded on both sides of the intermediate base layer. The surface composite layer is composed of several surface material layers and glass fiber cloth layers alternately Composite, wherein the innermost glass fiber cloth layer of the surface composite layer is bonded to the intermediate base layer, and the outermost layer of the surface composite layer is a surface material layer; wherein

[0036] The preparation of the surface material layer: including the following raw materials: 6kg of magnesium oxide, 2.5kg of wood chips or straw powder and 2.5kg of HHD agent. After mixing the above raw materials, dry stirring for 5-10min, then adding 8kg of FHL solution and stirring again for 15-25min. The uniformity of the fine material reaches saturation; at this time, the sawdust absorbs the FHL solution to a saturated and stable stat...

Embodiment 3

[0039] The environment-friendly light-body composite keel board described in this embodiment includes an intermediate base layer and a surface composite layer bonded on both sides of the intermediate base layer. The surface composite layer is composed of several surface material layers and glass fiber cloth layers alternately Composite, wherein the innermost glass fiber cloth layer of the surface composite layer is bonded to the intermediate base layer, and the outermost layer of the surface composite layer is a surface material layer; wherein

[0040] Surface material preparation: Including the following raw materials: 10kg of magnesium oxide, 5kg of wood chips or straw powder, and 5kg of HHD agent. After mixing the above raw materials, dry stirring for 5-10min, then adding 12kg of FHL solution and stirring again for 15-25min. The uniformity of the fine material reaches saturation; at this time, the sawdust absorbs the FHL solution to a saturated and stable state, and it will no ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com