Quickly-propelled low-power and energy-saving hydraulic servo-actuator

A hydraulic servo and energy-saving technology, which is applied in the direction of mechanical equipment, can solve the problems of large throttling and heating, increased operating costs, increased volume and complexity, etc., and achieves fast response, improved reliability and high control precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

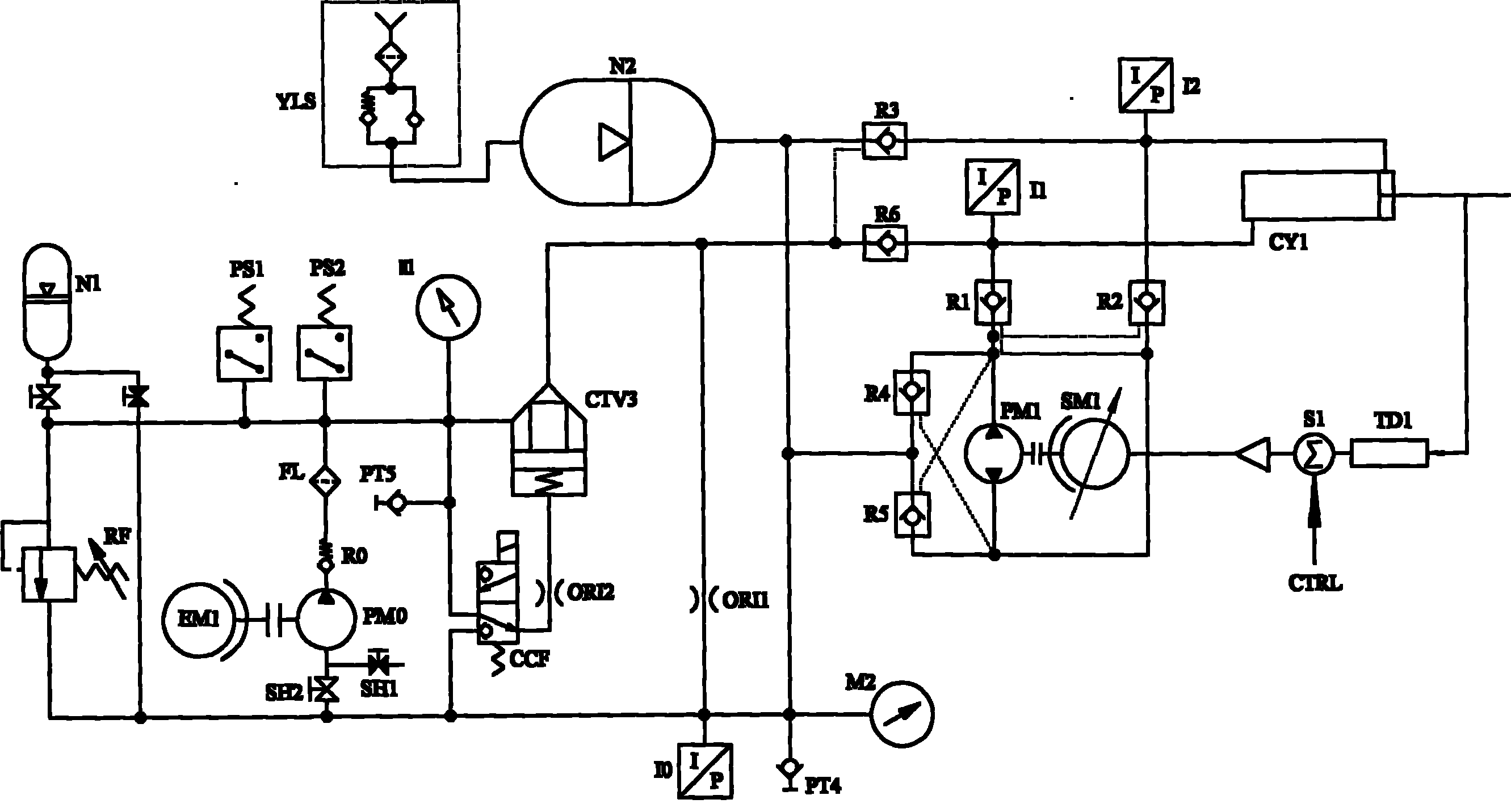

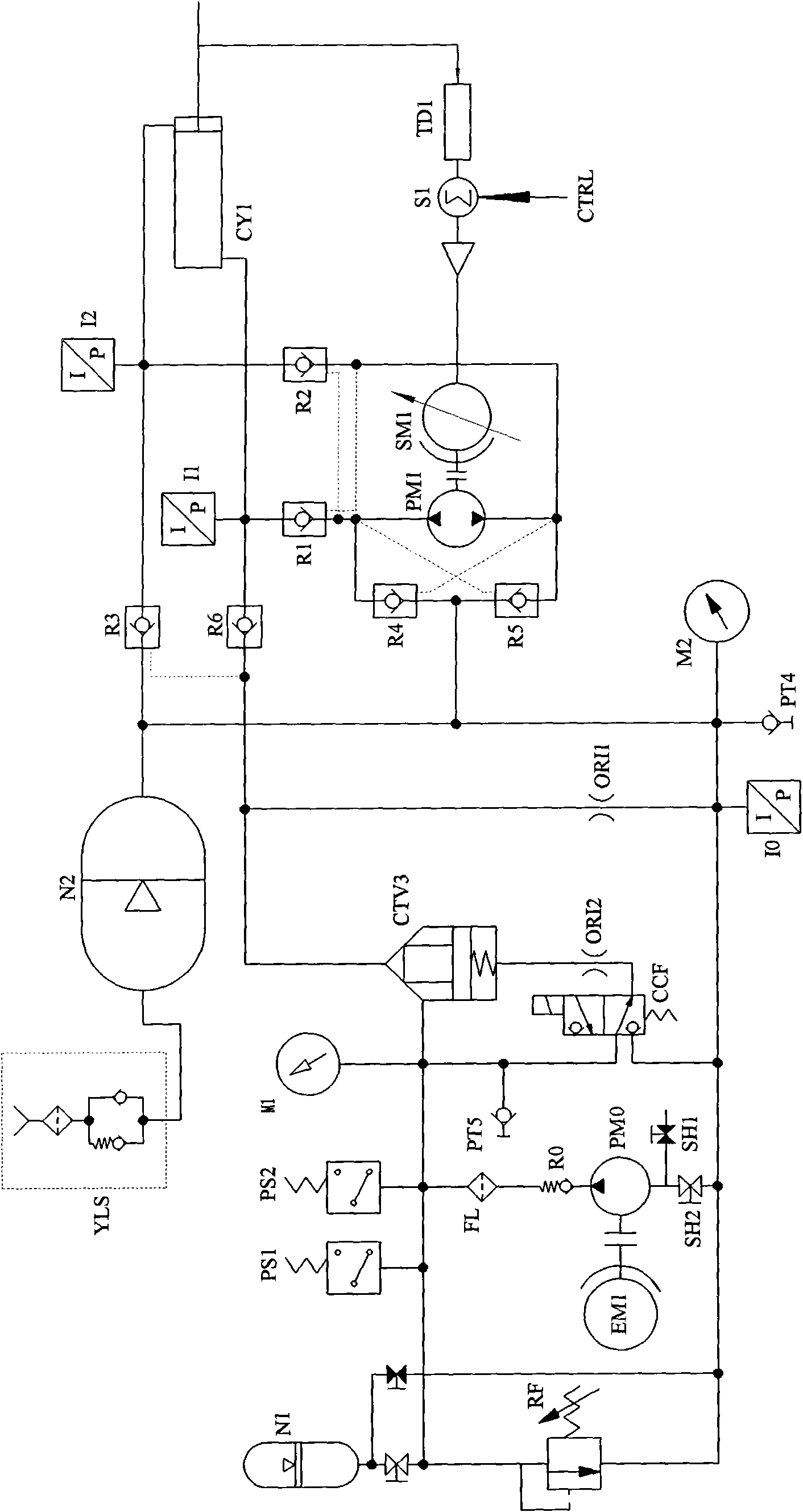

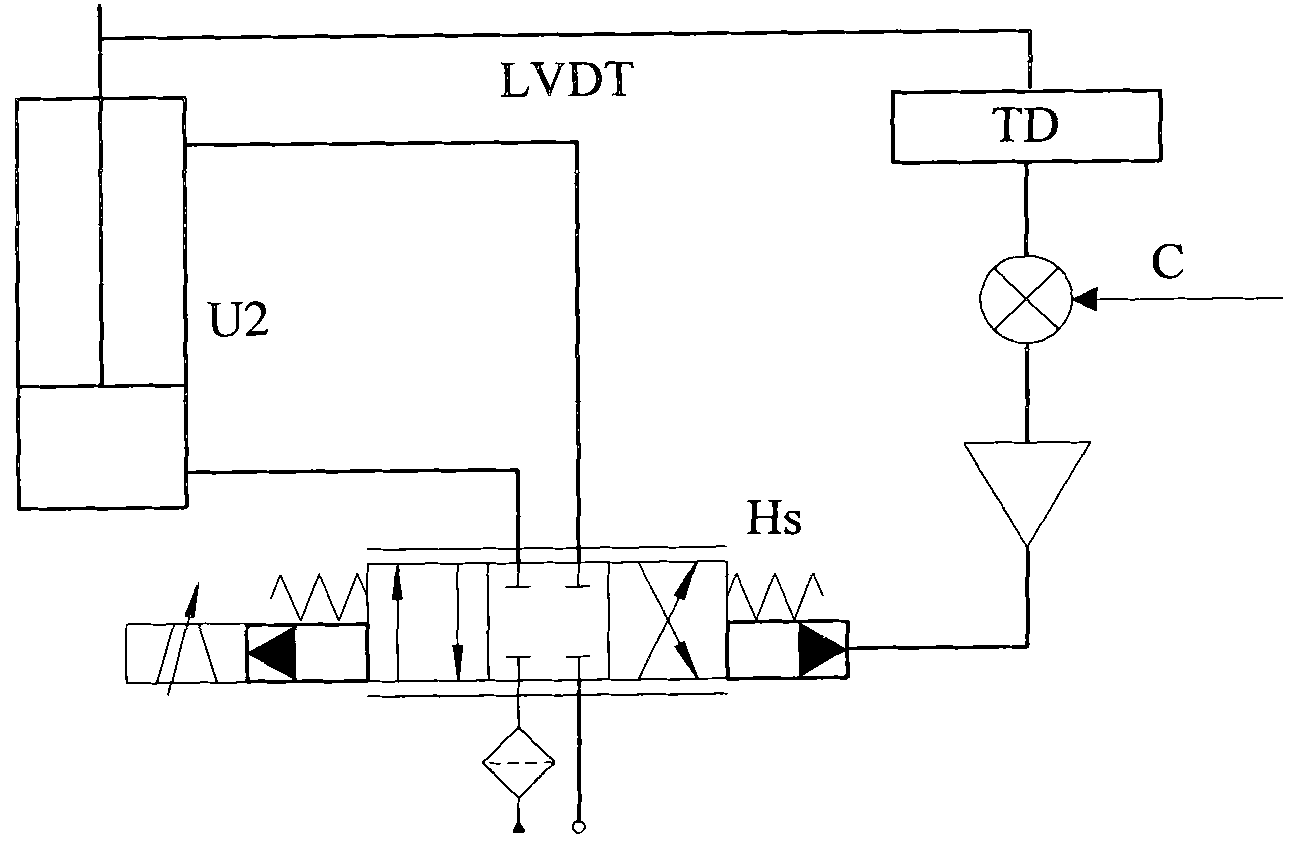

[0023] As shown in Figure 1, a fast-propelling low-power energy-saving hydraulic servo actuator provided by the embodiment of the present invention includes an execution circuit and an oil tank N2; the execution circuit includes a servo motor SM1, a bidirectional pump PM1, an oil cylinder CY1, Two lock valves and two oil supply valves; the servo motor SM1 is connected to and controls the operation of the two-way pump PM1; the oil cylinder CY1 has two working chambers, one of which is a rod chamber and the other is a rodless chamber. cavity; the two-way pump PM1 has two oil ports, respectively the first oil port and the second o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com