Salient shoulder type static pressure tangential small-hole gas bearing

A technology of gas bearings and shoulders, which is applied in the field of static pressure tangential small hole gas bearings, can solve the problems of increasing gas consumption and affecting the energy consumption index of the complete set of air separation equipment, so as to achieve the reduction of gas supply, the reduction of friction factors, and the reduction of The effect of overall energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

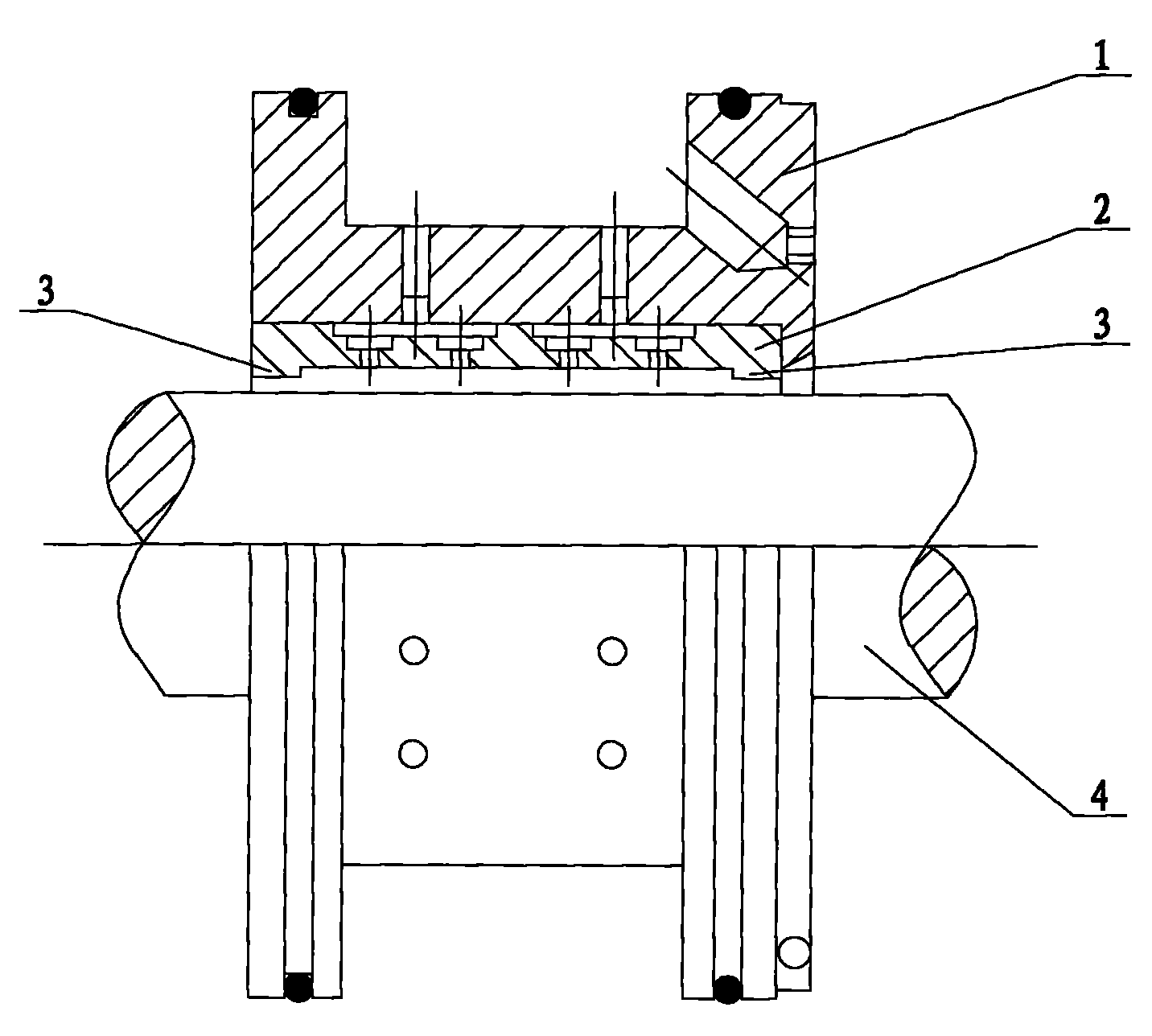

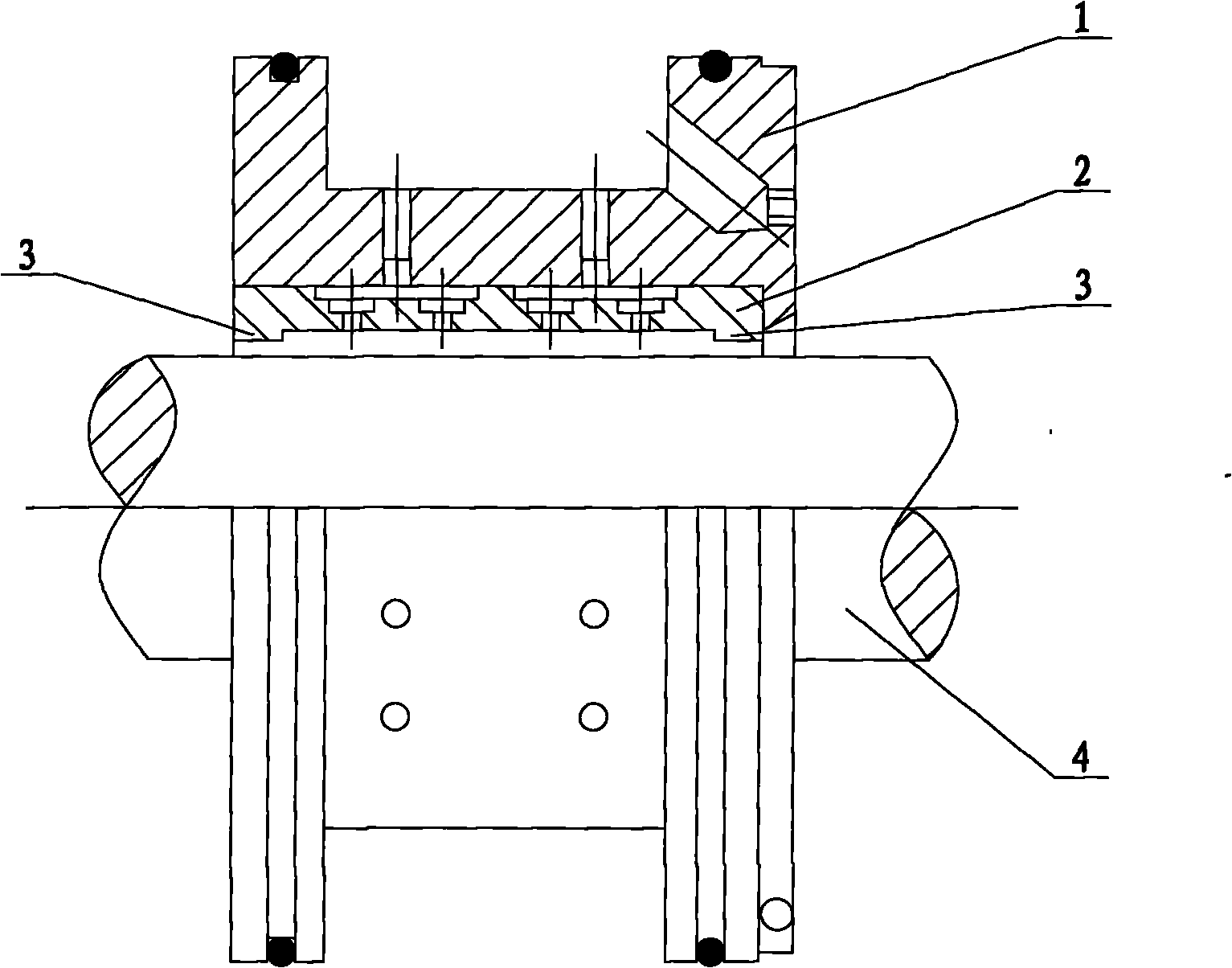

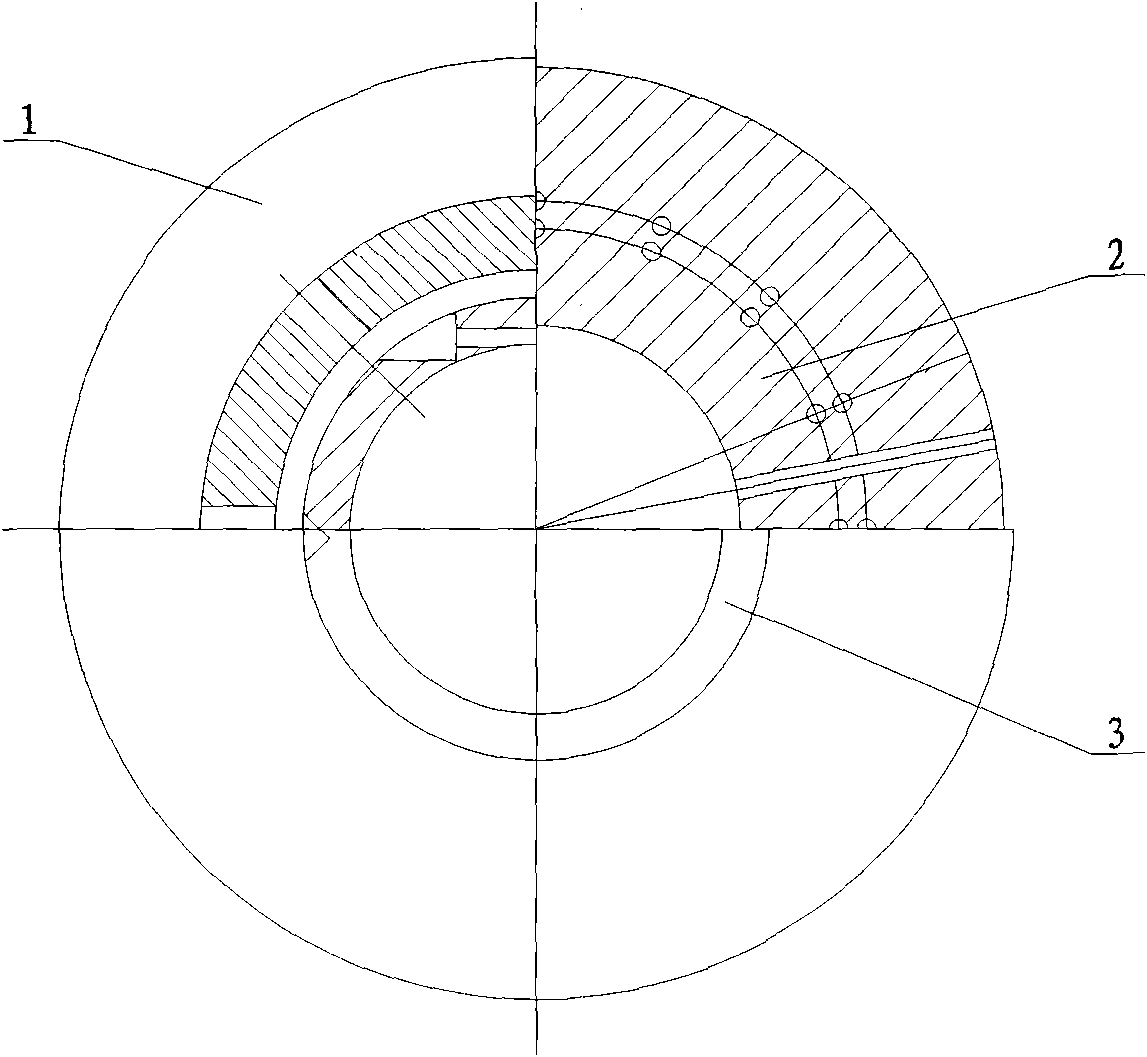

[0018] A shoulder-type static pressure tangential small hole gas bearing, its structure is shown in Figure 1-2, the bearing is a tangential small hole gas bearing, the shape is cylindrical, the radius of the two ends of the bearing is larger than the radius of the middle part, the bearing is The bearing adopts the composite structure of the bearing body 1 and the raised shoulder bearing bush 2, the bearing body 1 is made of H62 brass material, and the raised shoulder bearing bush 2 is made of J105 graphite copper material. The bearing body 1 is sleeved on the outer side of the raised shoulder bearing bushing 2. The longitudinal section of the raised shoulder bearing bush 2 is a ring structure, and the inner side of the two ends of the raised shoulder bearing bush 2 is provided with a shoulder 3. The width of the shoulder 3 is is 1.5mm and the depth is 0.02mm. The shoulder-type static pressure tangential small hole gas bearing sleeve is set on the crankshaft 4. Since the distan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com