Heat dissipation method for friction surface of wet clutch of automobile gear box

A technology for wet clutches and automotive gearboxes, applied in clutches, friction clutches, mechanical drive clutches, etc., can solve problems affecting clutch durability, limiting clutch heat capacity, and torque transmission, etc., to enhance momentum and energy exchange and improve mixing , Increase the effect of heat transfer temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

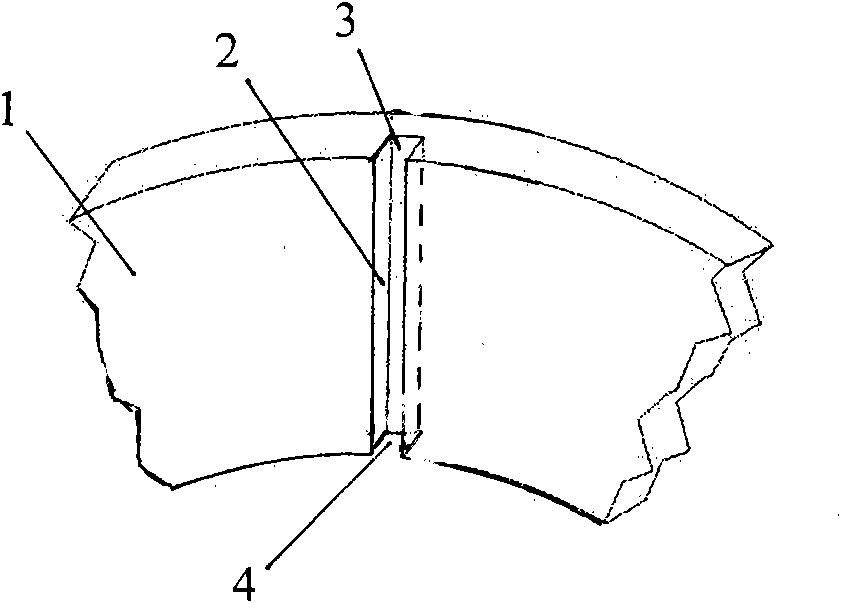

[0017] Figure 1 ~ Figure 4 The cooling oil sump shown is taken from a section of the automatic transmission lockup clutch annular plates. figure 1 It is a schematic diagram of the structure of the cooling oil groove in the prior art. The cooling oil groove 2 is radial and straight, and the highest temperature usually occurs on the outer diameter of the friction surface, and the heat dissipation effect is not good.

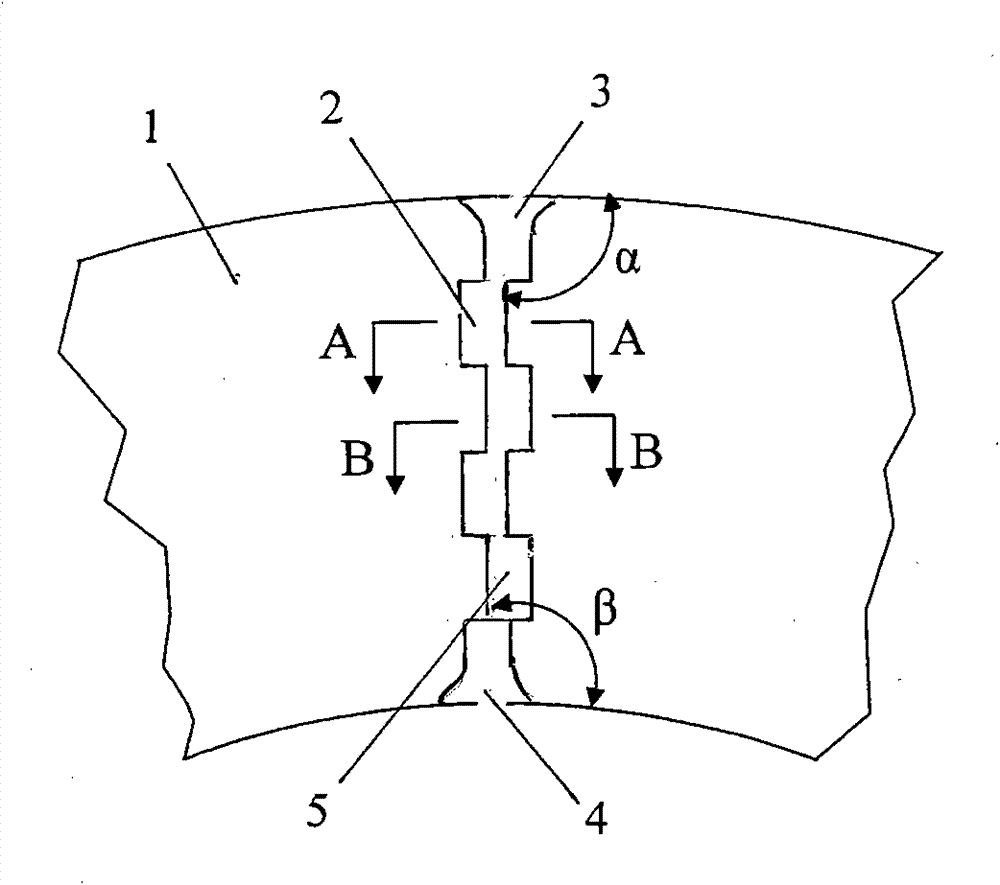

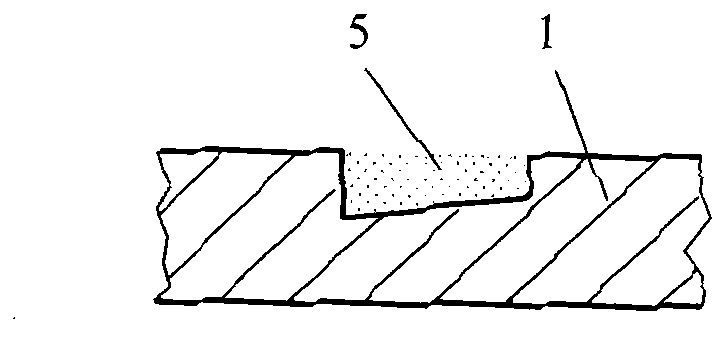

[0018] Figure 2 ~ Figure 4 It is a schematic diagram showing the direction of the structure of the cooling oil tank and the cross-sectional shape of the grid-shaped oil tank in the present invention. As can be seen from the figure, a heat dissipation method for the friction surface of a wet clutch of an automobile gearbox is characterized in that the cooling oil flows from the oil inlet 3 on the outer diameter of the driven disc to the oil outlet 4 on the inner diameter of the driven disc through the cooling oil groove 2 and flows out , the cooling oil flows in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com