Liquid heating device, core of the the device and a fabricating method thereof

一种加热装置、部件的技术,应用在流体加热器、水加热器、照明和加热设备等方向,能够解决易毁坏、易形成裂痕、毁坏电路等问题,达到省却电子控温、热传率促进、高热传系数的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

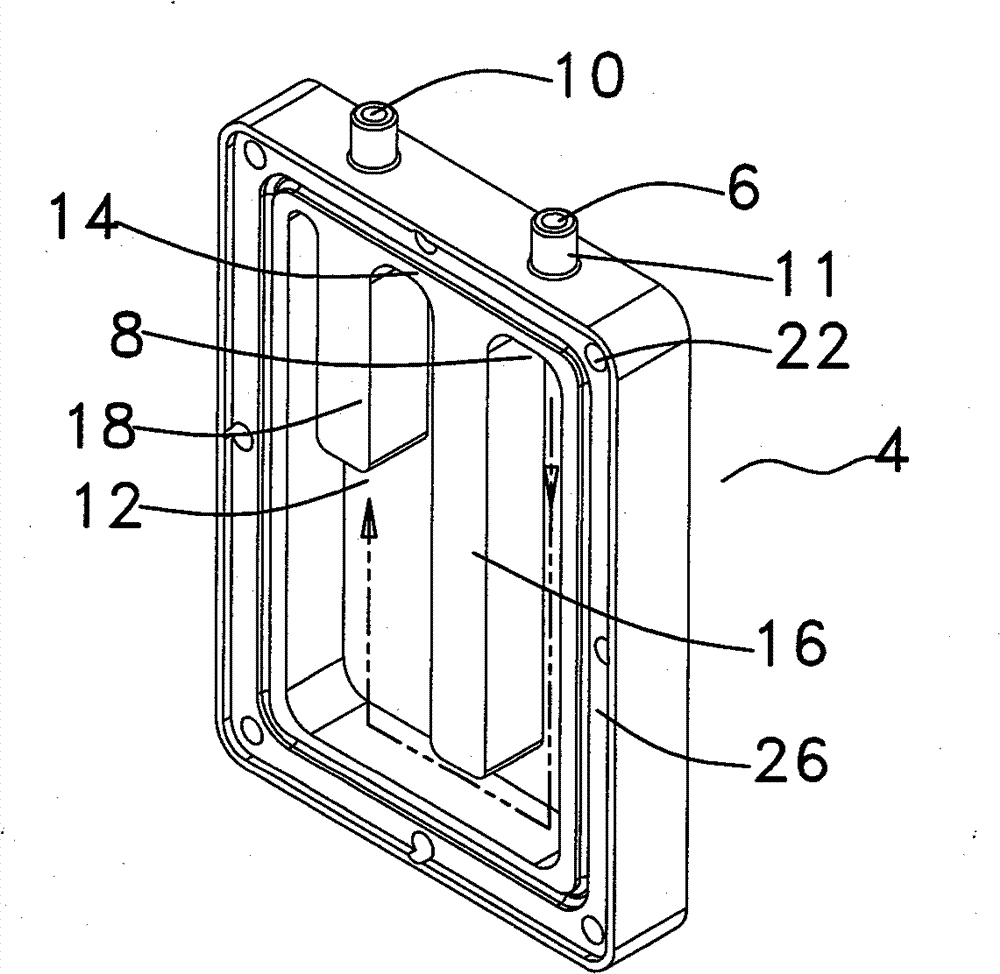

[0051] Attached Figure 1 to Figure 6 , Is a specific embodiment of a liquid heating device (such as a drinking water heating device). As attached figure 1 As shown, the liquid heating device is usually labeled 2. Two joining positions 11 are attached to the top of the liquid heating device 2.

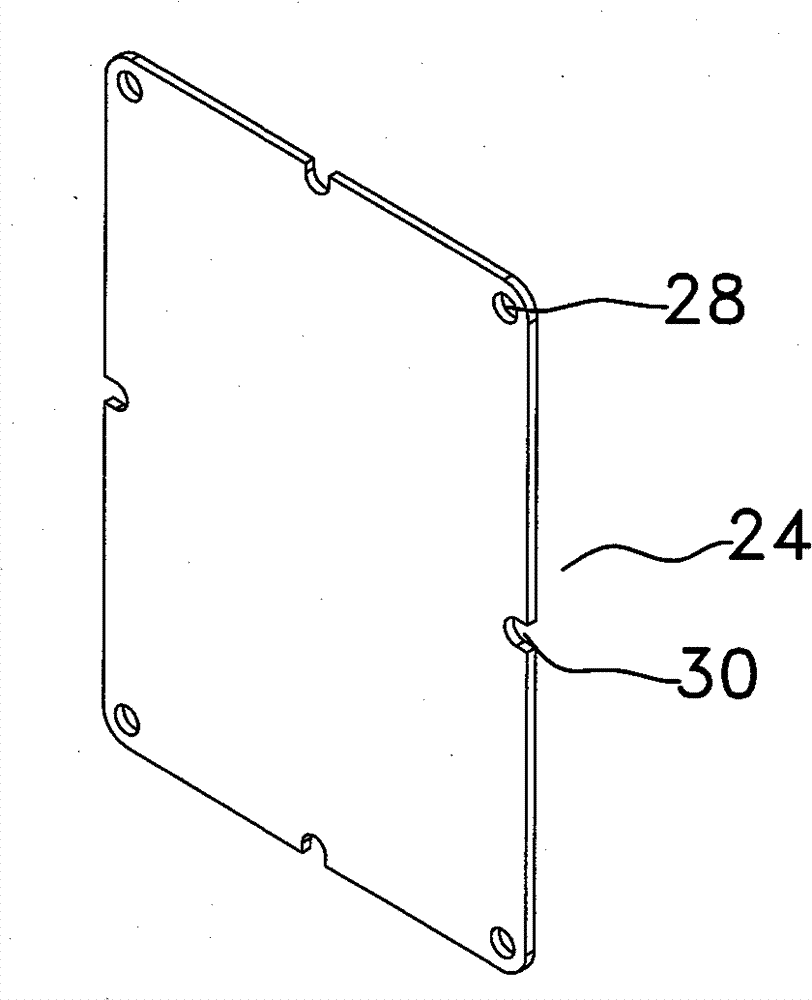

[0052] figure 2 It is an exploded view of the main parts of the liquid heating device. The liquid heating device 2 includes a core component 4 in the middle part of the device 2. The core part 4 provides a liquid inlet part 6 named as the first channel 8 through which the liquid is introduced into the core part 4. The core component 4 also provides a liquid outlet component 10 named as the second channel 12, through which the heated liquid leaves the core component 4. image 3 Independently show the core components 4 more clearly. Refer to Figure 1 to Figure 3 , The water inlet part 6 and the water outlet part 10 are adapted to each other with the joint position 11. The core compone...

Embodiment 2

[0062] The difference between the second embodiment and the first embodiment is that the liquid heating device 2 adopts a core component 40 with a different structure in the second embodiment. As attached Figure 7 As shown, here is shown a clearer or narrower channel 42 attached to the core component 40, and the main part of the channel 42 is arranged in parallel with the direction of the water inlet or outlet. It can be understood here that when comparing the core component 4 in the first embodiment, this core component 40 has a relatively large inner surface area, so that the water source tends to contact the surface of the channel 42 when it flows through, which can increase heat transfer to The efficiency of the liquid.

Embodiment 3

[0064] Figure 8a , 8b and 8c disclose other three different core components 44, 46 and 48, and their common point is that the water inlet and outlet components are both arranged on top of the core component. When they are all rotated 90 degrees clockwise, it can be considered that the water inlet part and the water outlet part are arranged on the side of the core part, and the water outlet part is arranged above the water inlet part. One of the features of the core component 44 is that the water inlet component 50 and the corresponding passage 52 are lower than the water outlet component 56 and the corresponding passage 54. Similarly, the core component 44 supplies a temporary storage assembly 58 or storage on the other side of the channel 52. The temporary storage component 58 can be used to temporarily store vapor or vaporized water in the core component 44 so that the vapor does not easily flow out of the core component 44. This can reduce the amount of steam discharged fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com