Low-side driving circuit for vehicle-mounted relay

A low-side drive and relay technology, applied in relays, circuits, electrical components, etc., can solve the problems of overheating of the coil, inability to pull in at high temperature and low voltage, smaller coil current, and poor heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

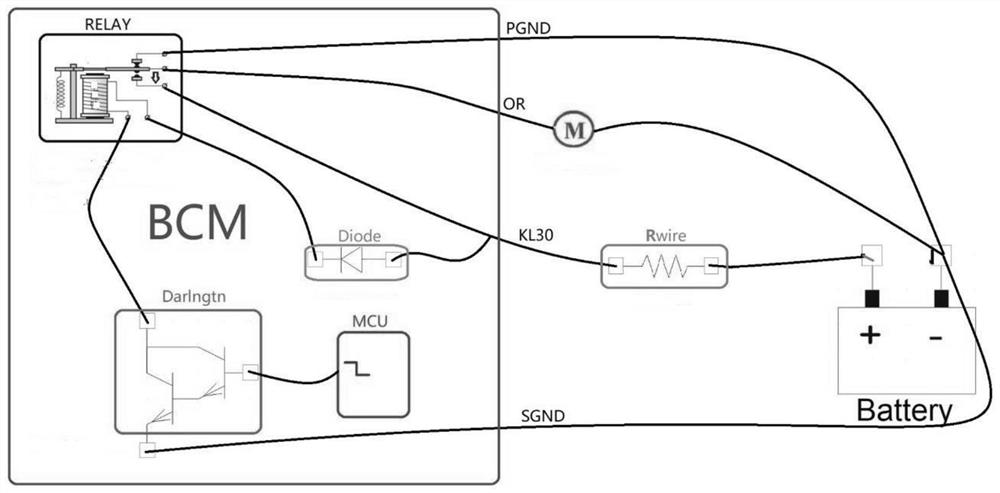

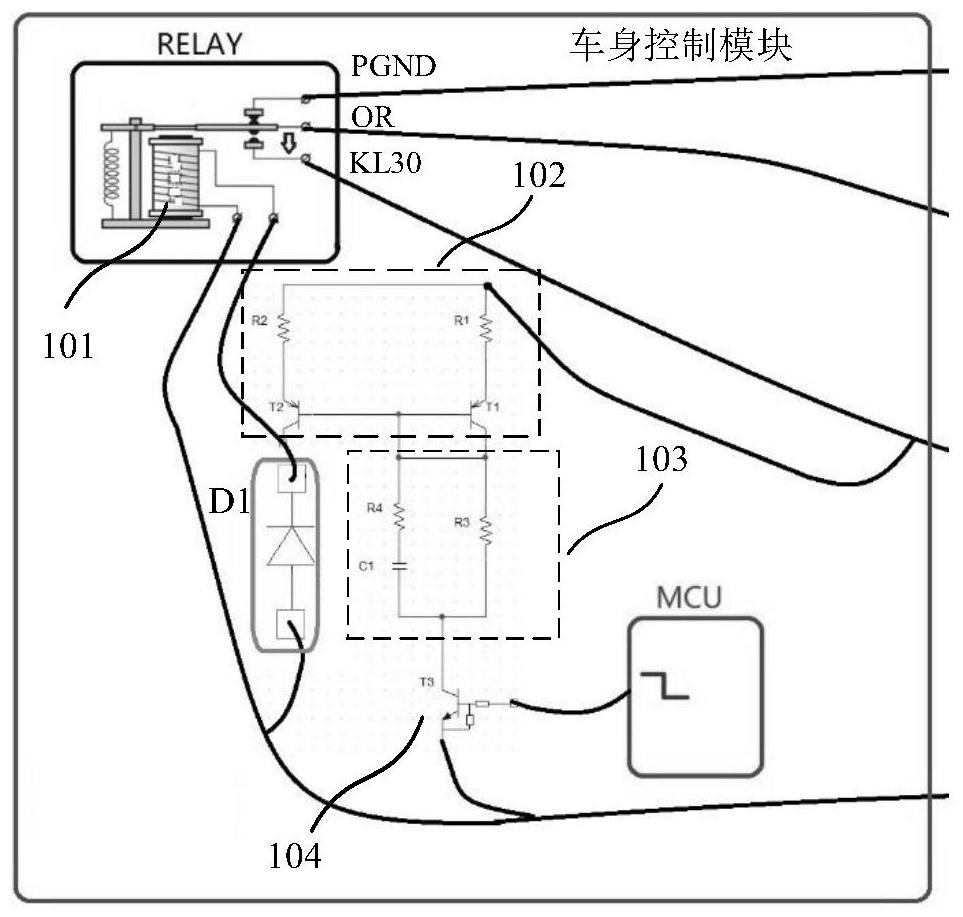

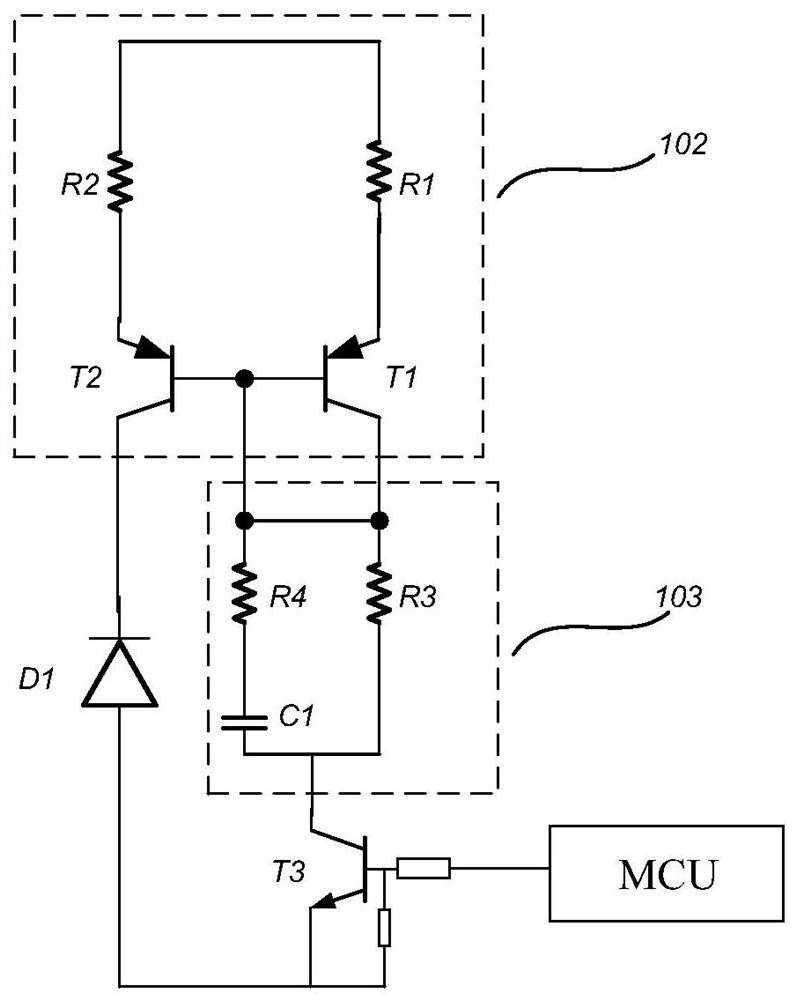

[0047] This embodiment provides a low-side drive circuit for a vehicle-mounted relay. refer to figure 2 , image 3 The vehicle-mounted relay low-side drive circuit includes a relay RELAY, a triode mirror circuit 102, a time-varying resistance circuit 103, a diode D1, a controllable switch 104, and a main control unit.

[0048] The relay RELAY includes an armature OR, a normally open contact KL30, a normally closed contact PGND, and a coil 101; the triode mirror circuit 102 includes an input terminal, a first output terminal, and a second output terminal; the input terminal is electrically connected to the normally open contact KL30, The first output end, the cathode of the diode are electrically connected to one end of the coil 101; one end of the time-varying resistance circuit 103 is electrically connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com