Portable gas sealability test monitoring analyzer of turbonator

A steam turbine generator and gas sealing technology, which is applied in the direction of using liquid/vacuum degree to measure liquid tightness and measuring the acceleration and deceleration rate of fluid, etc. Wide operating temperature range, changing reading error, good anti-interference performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

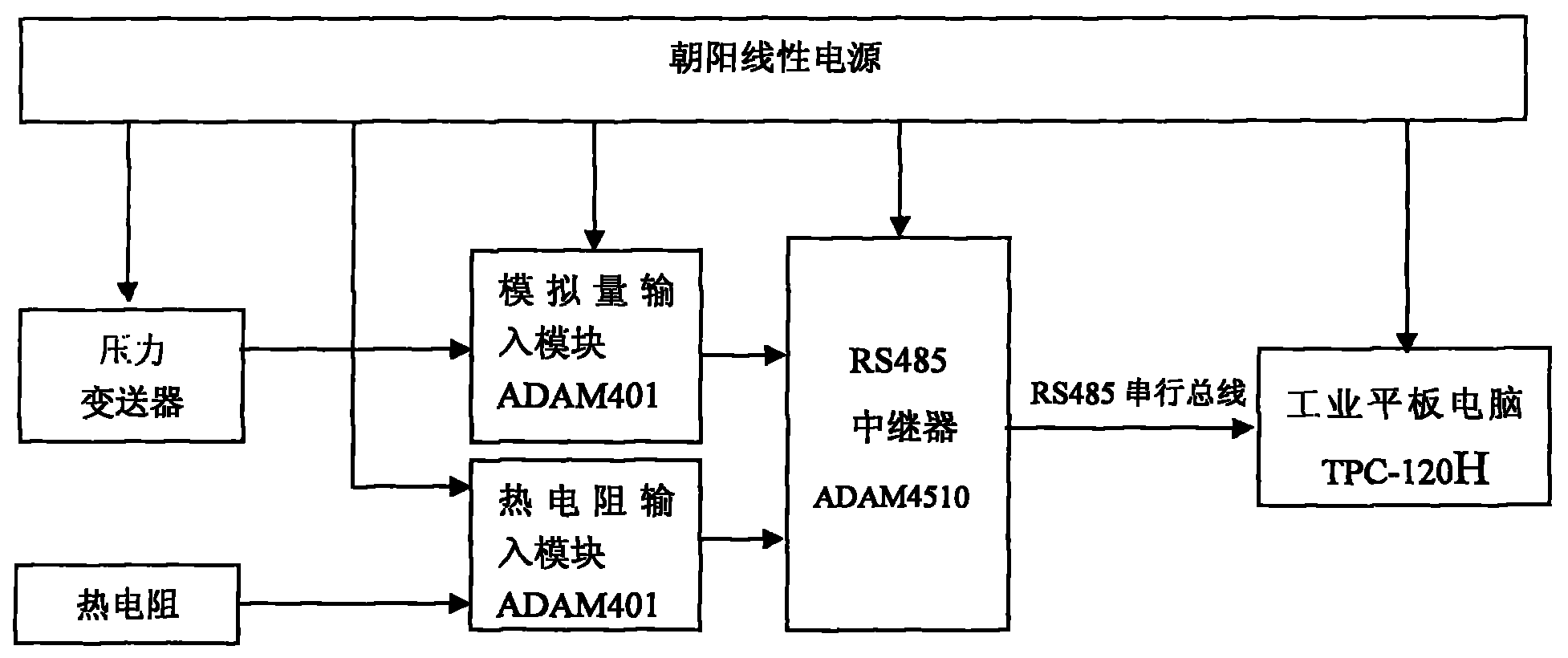

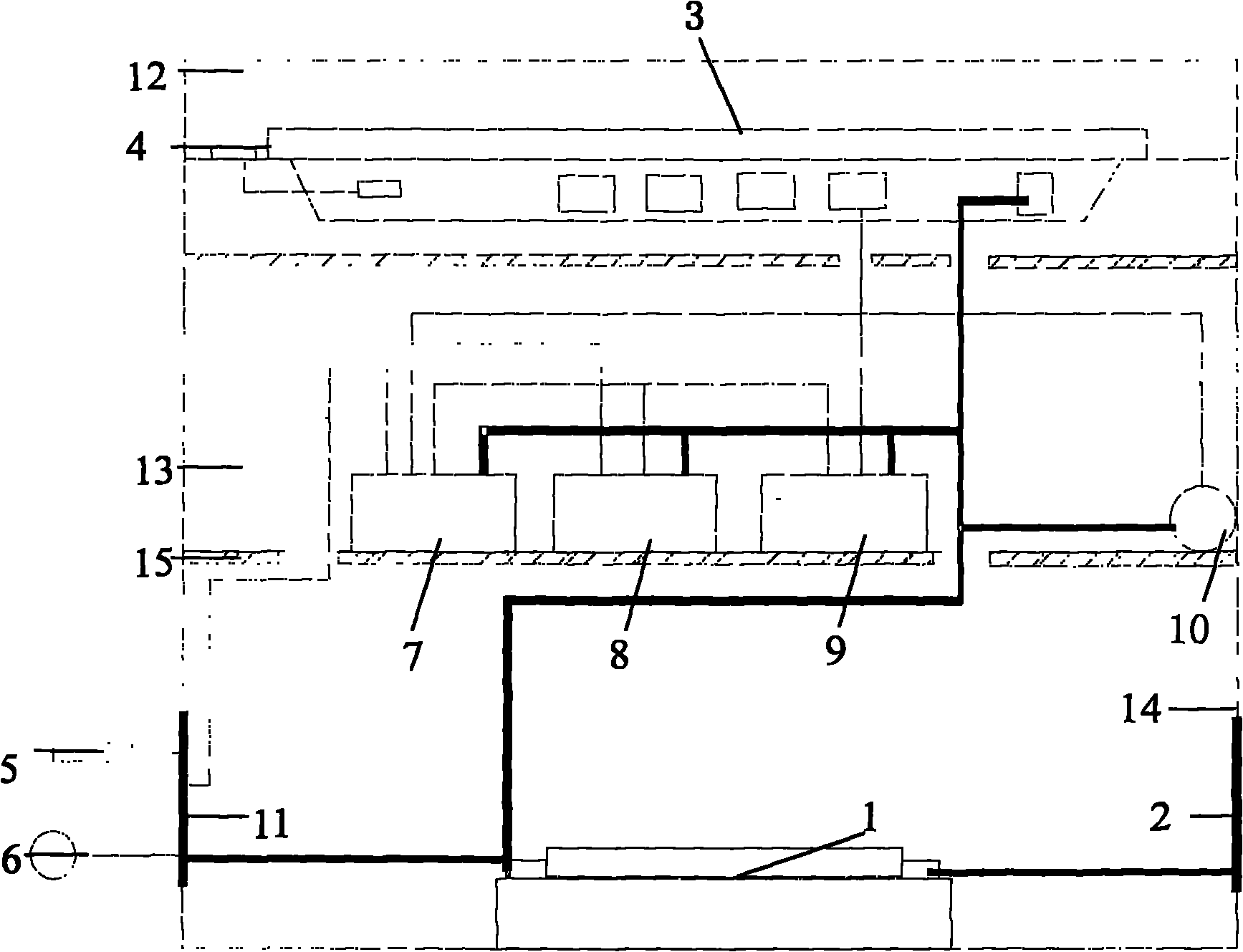

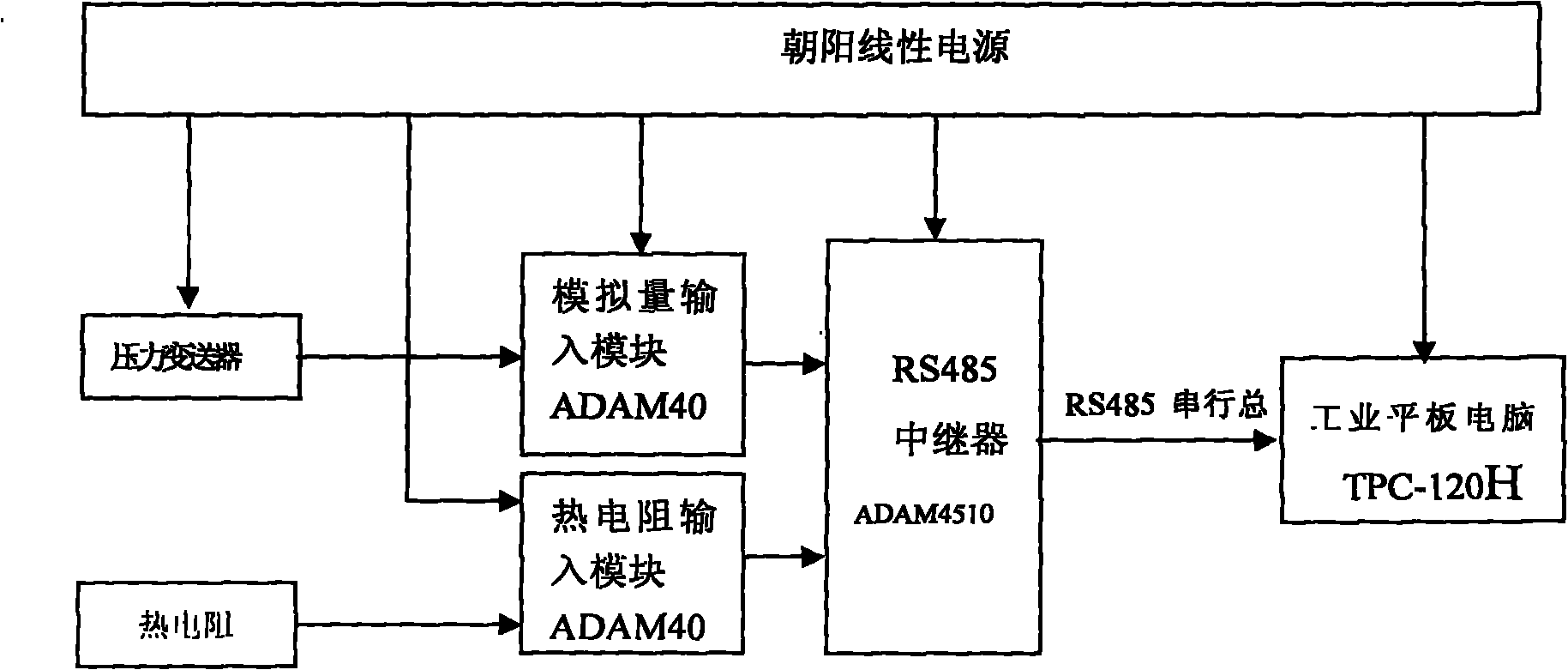

[0009] As shown in Figure 1, a portable turbogenerator gas tightness test monitoring analyzer, the interior of the chassis 12 is divided into three layers, the fixed transmitter access terminal block 11 is installed on the left box plate 13 at the bottom of the chassis, and the chassis The fixed power supply access terminal 2 is installed on the bottom right box plate 14, and the pressure transmitter 5 and thermal resistance 6 are connected to the terminal block 11 of the transmitter access terminal through leads, which are the pressure transmitter 5 and the industrial panel computer 3 And the linear power supply 1 powered by the multi-channel data acquisition module is fixed at the bottom of the box, the analog input module 7, Advantech analog input module 7 model: ADAM4017, Advantech thermal resistance input module 8, Advantech thermal resistance input module 8 model: ADAM4015 The pressure transmitter 10 for atmospheric pressure is installed and fixed on the middle layer 15 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com