Composite optical eddy generation method and device thereof

A method of generating optical vortices, applied in optical recording/reproducing/erasing methods, recording/reproducing/erasing using optical interference patterns, radiation/particle processing, etc., can solve the difficulties and difficulties of parallelism and coaxiality Large and other problems, to achieve the effects of variety, simple production process, and increased storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

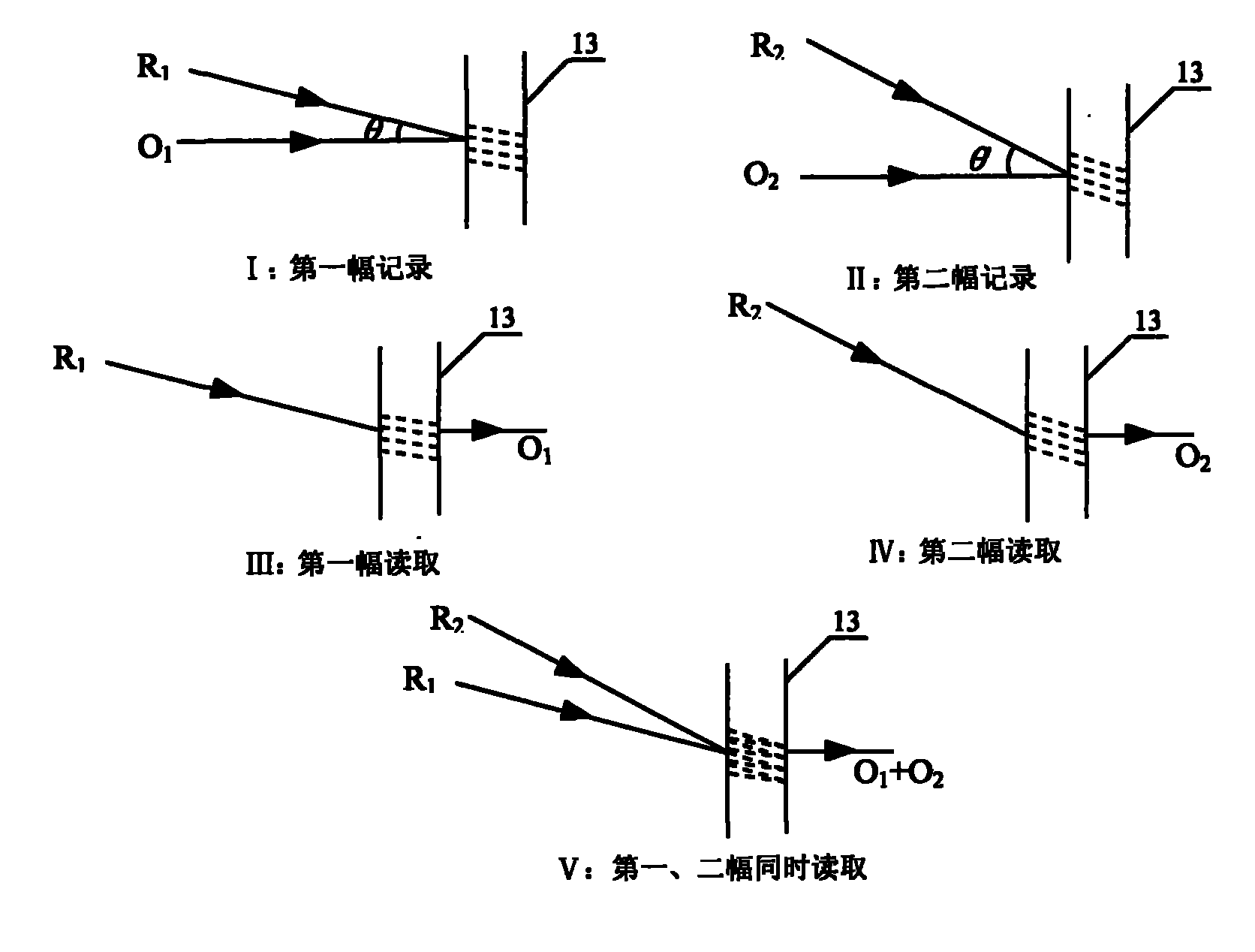

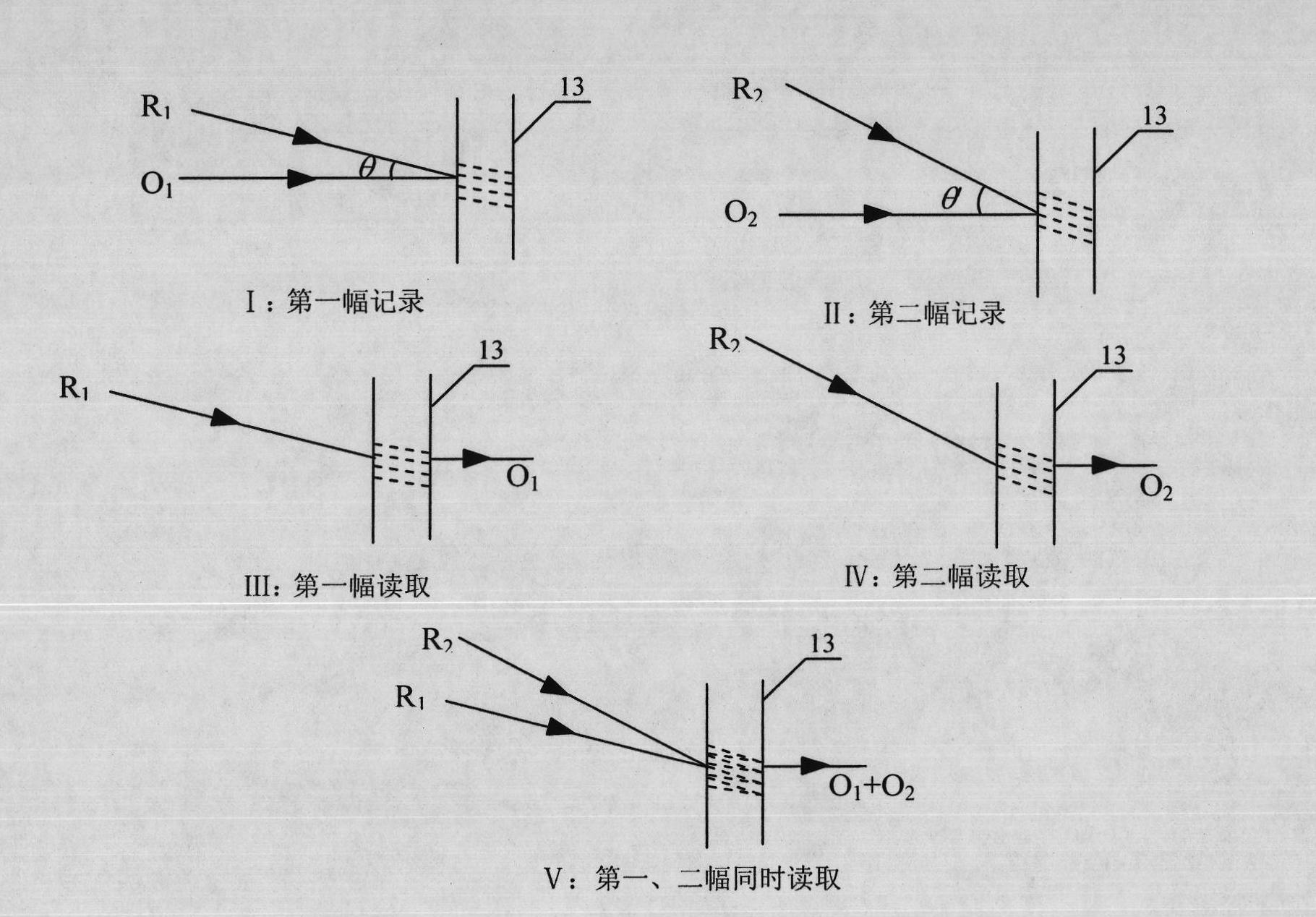

Embodiment 1

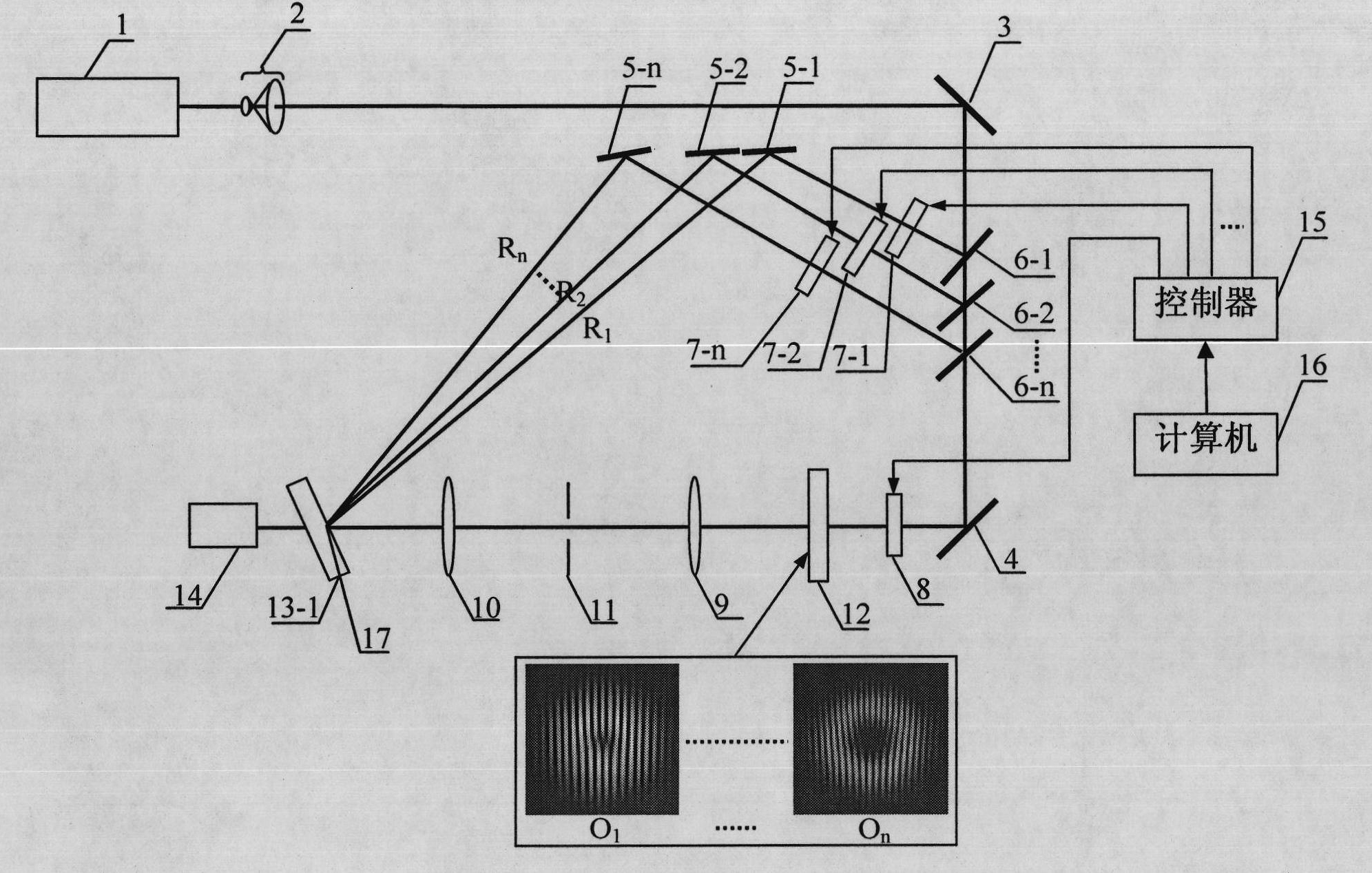

[0037]Please refer to Fig. 2, which is the main optical path structure of the first embodiment of the method for producing a composite optical vortex proposed by the present invention, including a laser light source 1, a beam expander 2, a second beam expander, and A reflecting mirror 3, beam splitter 6-1, by being arranged on the first reference light path shutter 7-1 and reference light path reflector 5-1 on this beam splitter 6-1 reflected light path; 1 the beam splitter 6-2 on the transmitted light path and the second reference light path shutter 7-2 and the reference light path reflector 5-2 on the reflected light path; ...; the nth on the reflected light path of the beam splitter 6-n A reference light path shutter 7-n and a reference light path reflector 5-n, the second reflector 4 on the transmission light path of the beam splitter 6-n, the main shutter 8, the vortex plane holographic generator 12, the first Fourier A leaf transform lens 9 , a first pinhole filter 11 , ...

Embodiment 2

[0047] Please refer to FIG. 4 , which is the main optical path structure of the second embodiment of the method for producing a composite optical vortex proposed by the present invention, including a laser light source 1, a beam expander 2, a second beam expander, and a second optical path arranged on the outgoing light path of the laser light source 1 in sequence. A reflecting mirror 3, beam splitter 6-1, by being arranged on the first reference light path shutter 7-1 and reference light path reflector 5-1 on this beam splitter 6-1 reflected light path; 1 the beam splitter 6-2 on the transmitted light path and the second reference light path shutter 7-2 and the reference light path reflector 5-2 on the reflected light path; ...; the second on the reflected light path of the beam splitter 6-n n reference light path shutters 7-n and reference light path reflectors 5-n, the second reflector 4, the main shutter 8, the spiral phase plate vortex generator 18 on the transmission ligh...

Embodiment 3

[0051] Please refer to FIG. 5 , which is the main optical path structure of the third embodiment of the method for generating a compound optical vortex proposed by the present invention, including a laser light source 1, a beam expander 2, a second beam expander, and A reflecting mirror 3, beam splitter 6-1, by being arranged on the first reference light path shutter 7-1 and reference light path reflector 5-1 on this beam splitter 6-1 reflected light path; 1 the beam splitter 6-2 on the transmitted light path and the second reference light path shutter 7-2 and the reference light path reflector 5-2 on the reflected light path; ...; the nth on the reflected light path of the beam splitter 6-n A reference light path shutter 7-n and a reference light path reflector 5-n, a second reflector 4, a main shutter 8, a mode conversion vortex generator 19 on the beam splitter 6-n transmission light path, a reference light path reflector 5 The direction of the vortex is set so that the ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com