Small high-voltage ignition module power supply

A high-voltage ignition, module power supply technology, applied in electrical components, output power conversion devices, etc., can solve the problems of short high-voltage ignition spacing, poor ignition reliability, and difficulty in installation, and achieve large high-voltage ignition spacing, easy PCB installation, Easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

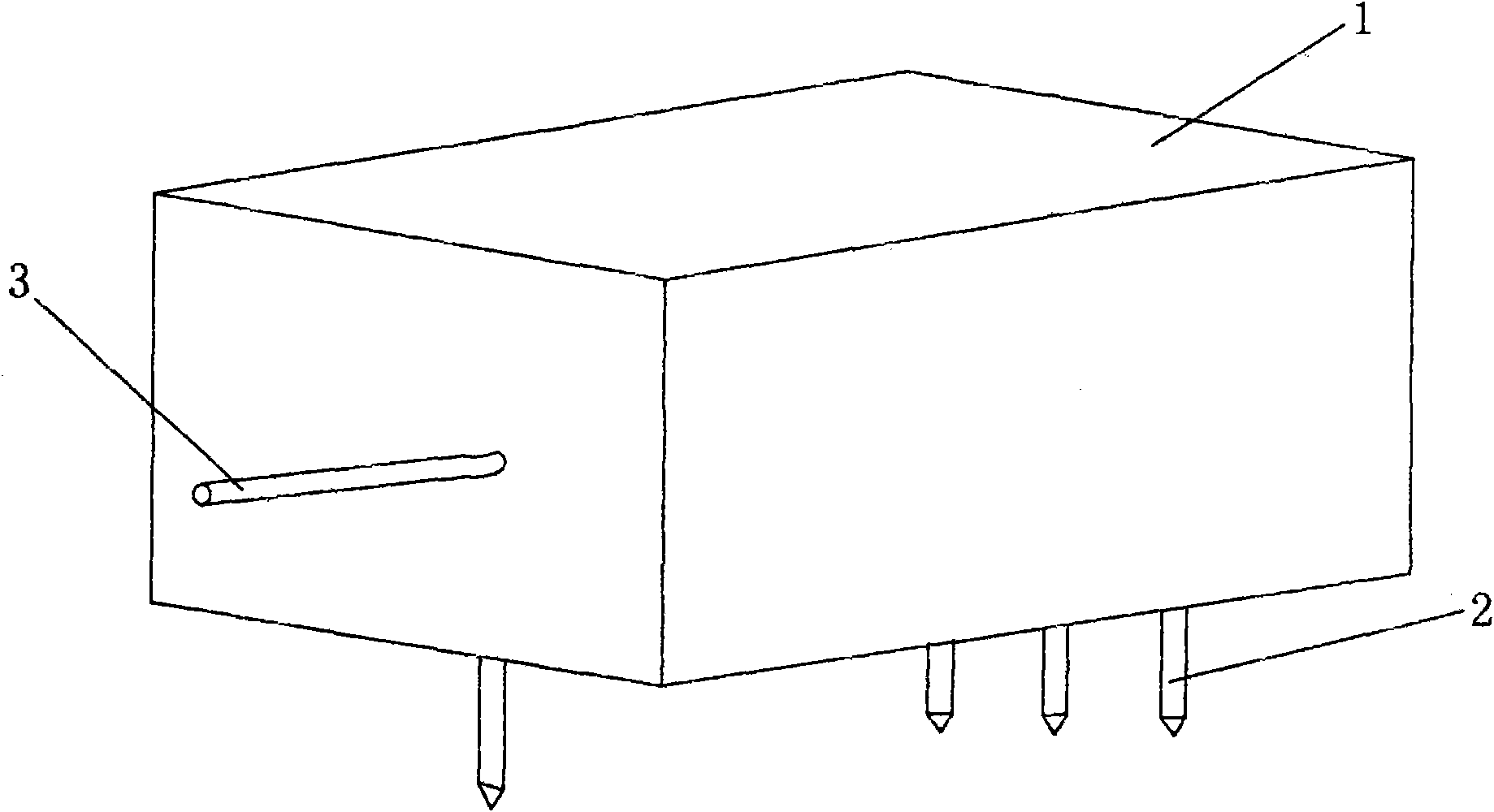

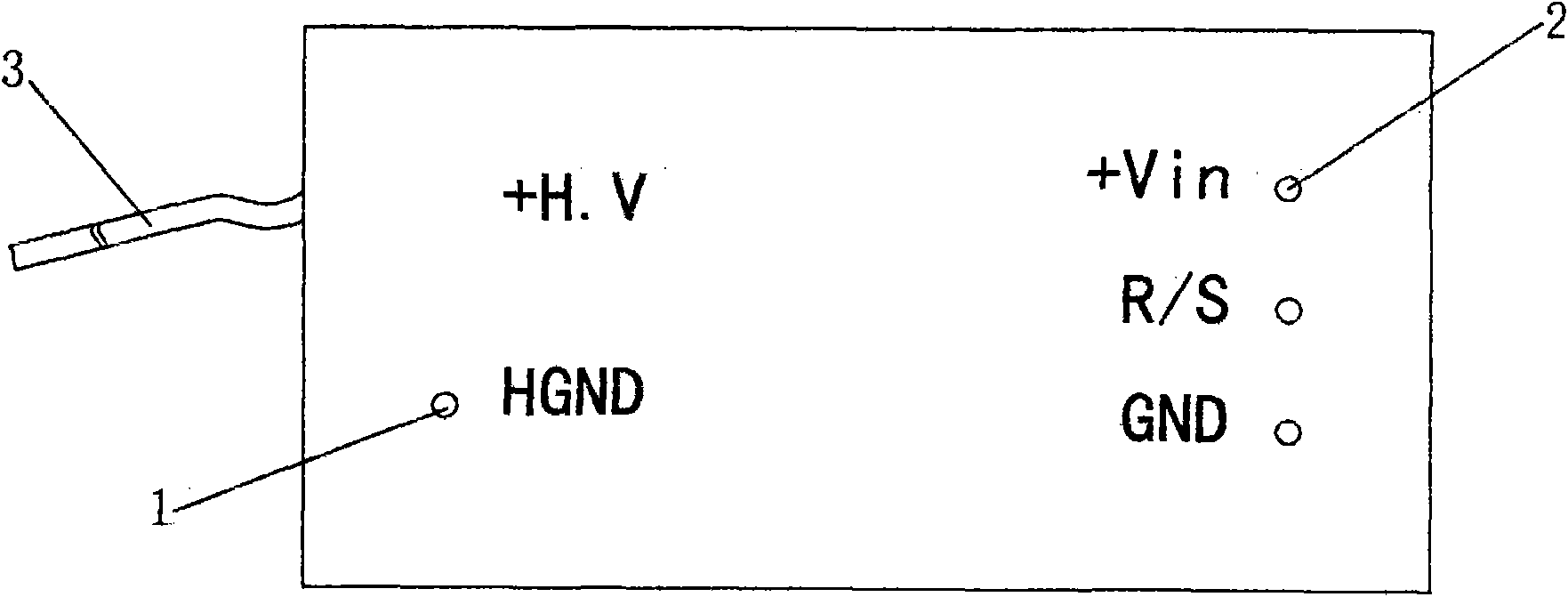

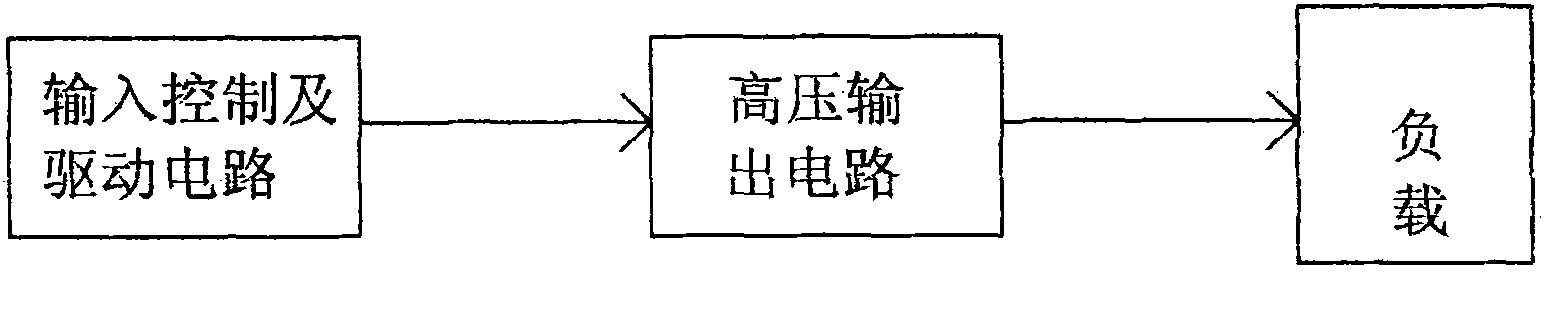

[0012] Such as figure 1 , 2 , 3, and 4, the small-sized high-voltage ignition module power supply includes a power circuit packaged in the housing 1. Several lead pins 2 and high-voltage output leads 3 are welded on the power circuit. The power circuit includes an input control and drive circuit, and a high-voltage output circuit. , the input control and drive circuit is connected to the high voltage output circuit;

[0013] In the input control and drive circuit, the anode of the diode D12 is connected to the input power supply terminal +Vin, the resistor R1 and the capacitor C10 are connected in parallel, the cathode of the diode D12 is respectively connected to one end of the resistor R1 and the resistor R2, the positive electrode of the capacitor C12, and a of the primary coil Lp of the transformer TRF terminal, the negative pole of capacitor C12 is connected to the input ground GND, the other end of resistor R1 is respectively connected to pin 1 of control tube T1, one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com