Film-forming type iodine disinfectant and preparation method thereof

A disinfectant and film-forming technology, which is applied in the field of film-forming disinfectant and its preparation, can solve the problems of unfavorable wound treatment and healing, easy sticking and staining of clothes, and insufficient convenience, so as to achieve good wound healing and strong bactericidal effect , good film-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the disinfectant, according to the content and components, first add iodine and potassium iodide to an appropriate amount of purified water to stir and dissolve to obtain an iodine and potassium iodide solution; then take another container to purify chlorhexidine acetate and benzyl alcohol at 50°C Dissolve in water, then add polyvinyl alcohol and stir to mix; add iodine and potassium iodide solution, and stir to mix. Pour the prepared solution into the liquid bottle and use it with the pump nozzle.

[0024] Shake the product up and down when using it, and then spray the disinfectant liquid against the wound, so that the liquid can completely cover the wound. After the liquid evaporates and dries up, a water-resistant film will be formed on the wound to protect the wound from healing.

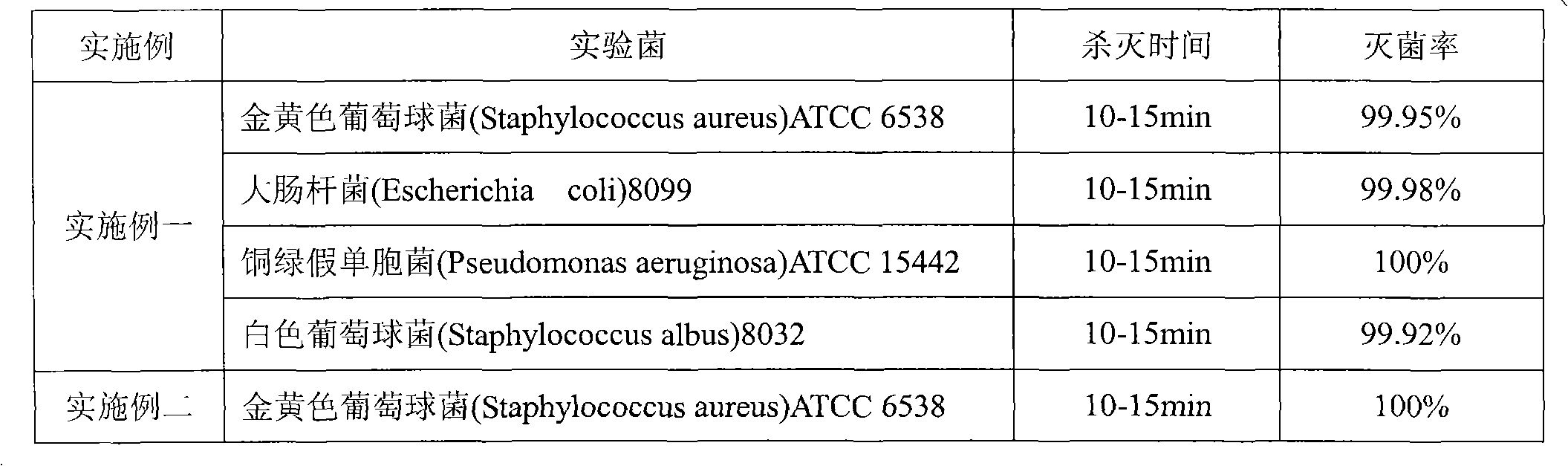

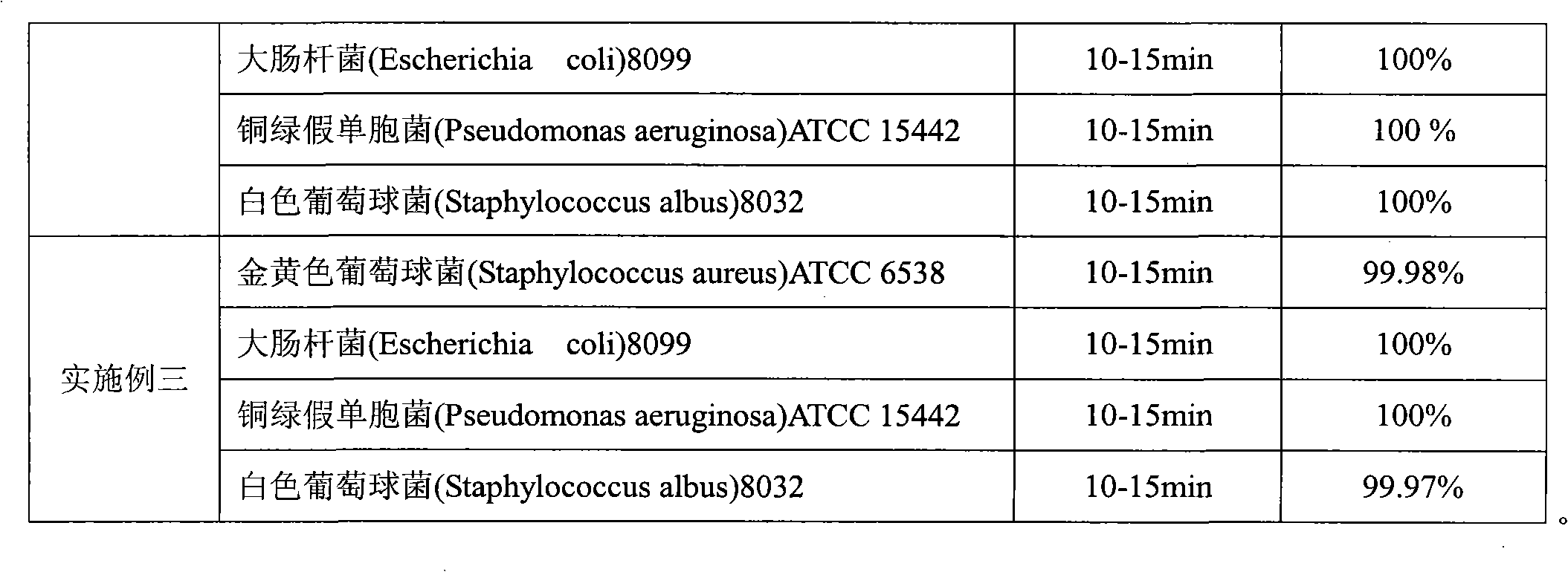

Embodiment 1

[0026] First add 0.045g of iodine and 0.045g of potassium iodide and add an appropriate amount of purified water and stir to dissolve; then take another container and dissolve 0.45g of chlorhexidine acetate and 0.5g of benzyl alcohol with purified water at 50°C, then add 12.0g of polyvinyl alcohol and stir to mix. Add iodine and potassium iodide solution, add purified water to 100g, stir and mix well. Pour the prepared solution into a liquid plastic bottle and use it with a pump nozzle.

Embodiment 2

[0028] First, add 0.055g of iodine and 0.055 of potassium iodide and add an appropriate amount of purified water to stir and dissolve; then take another container and dissolve 0.55g of chlorhexidine acetate and 2.0g of benzyl alcohol with 50°C purified water, then add 15.0g of polyvinyl alcohol and stir to mix. Add iodine and potassium iodide solution, add purified water to 100g, stir and mix well. Pour the prepared solution into a liquid plastic bottle and use it with a pump nozzle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com