Stainless steel honeycomb inclined-tube wave plate forming method for water treatment and forming device

A molding method and stainless steel technology are applied in the field of forming and forming devices for stainless steel honeycomb inclined tube wave plates for water treatment, which can solve the problems of inability to meet the stainless steel honeycomb inclined tube wave plates for precipitation, and achieve the advantages of being favorable for popularization and use and low molding cost. , good regularity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

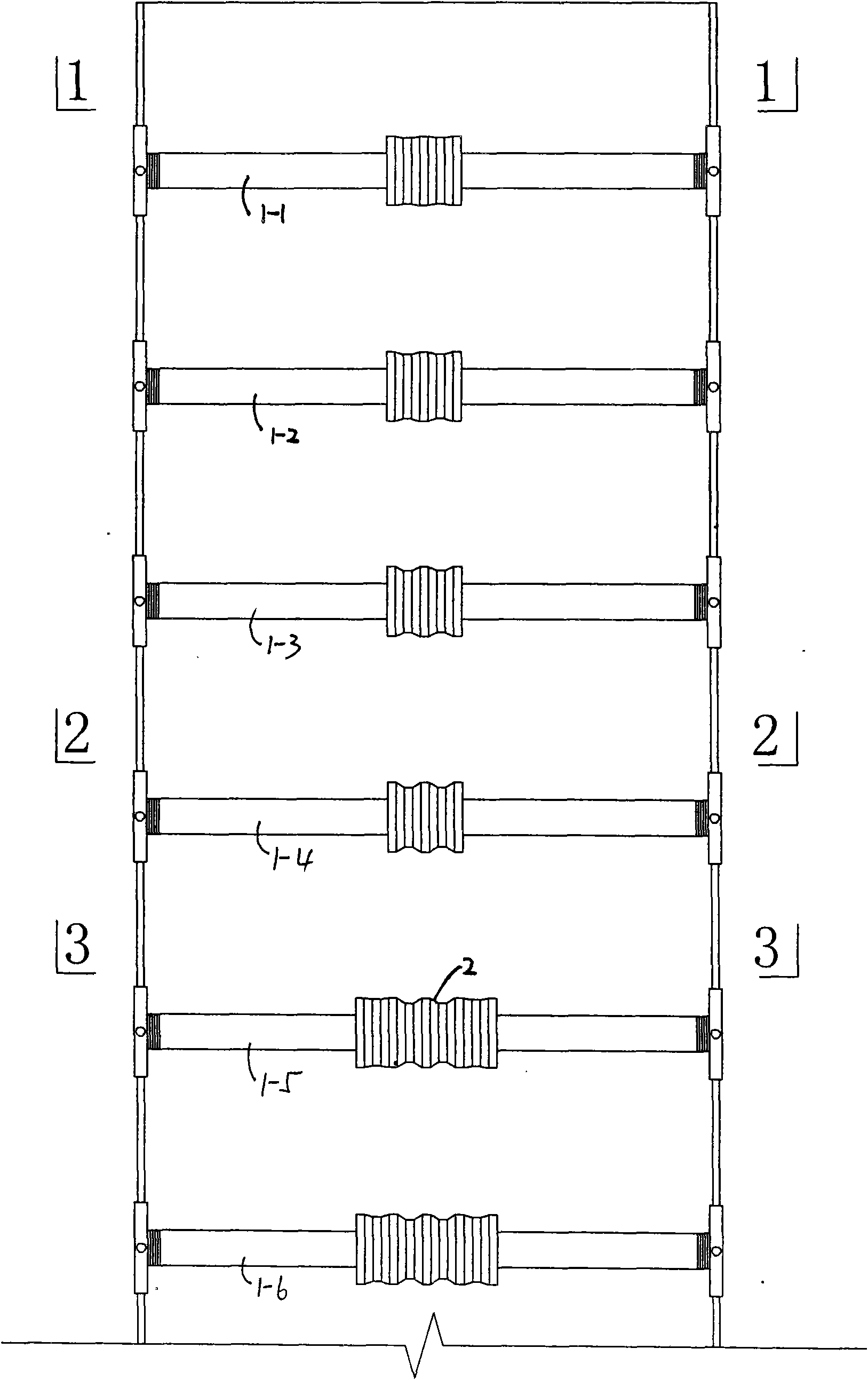

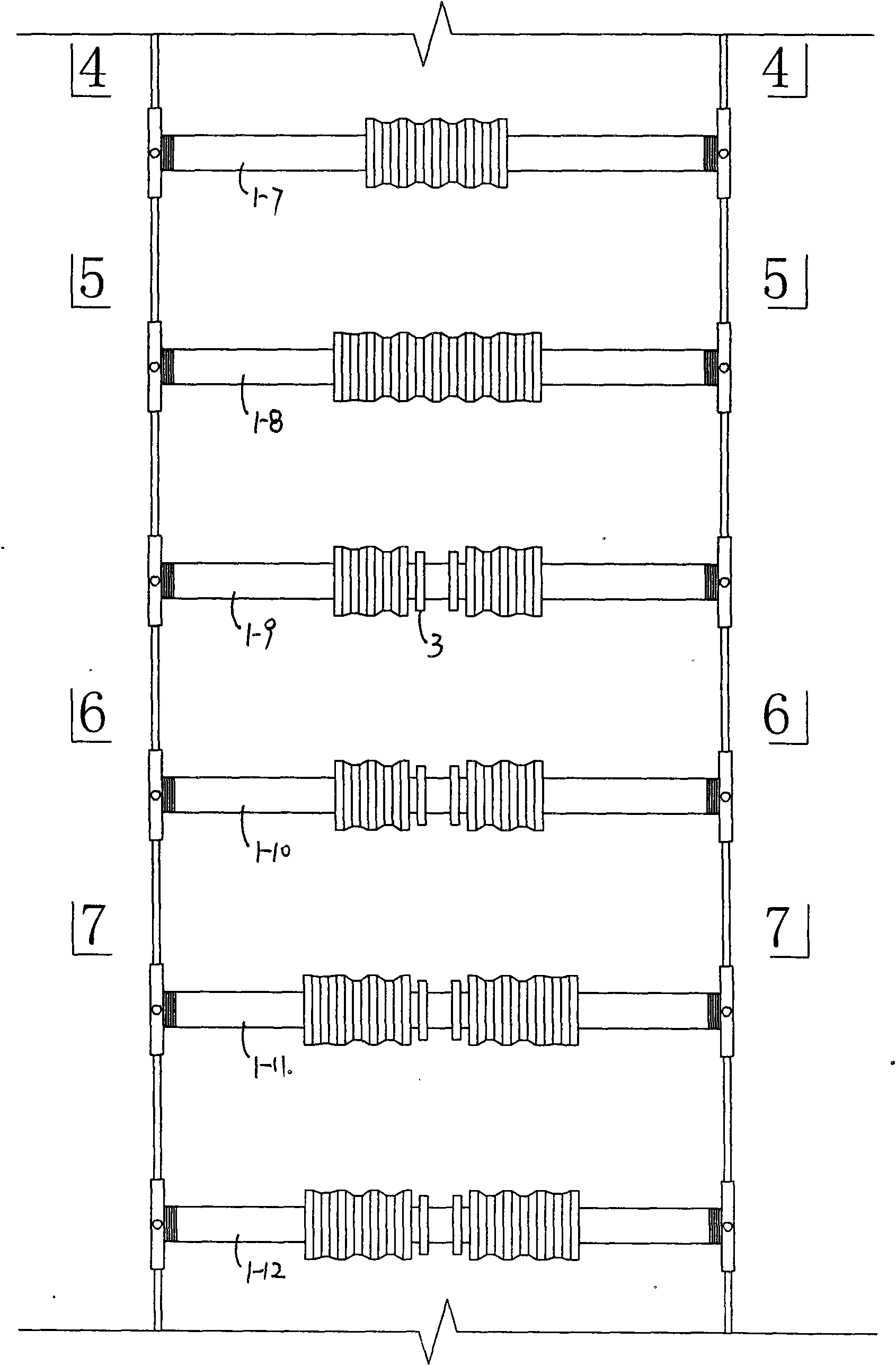

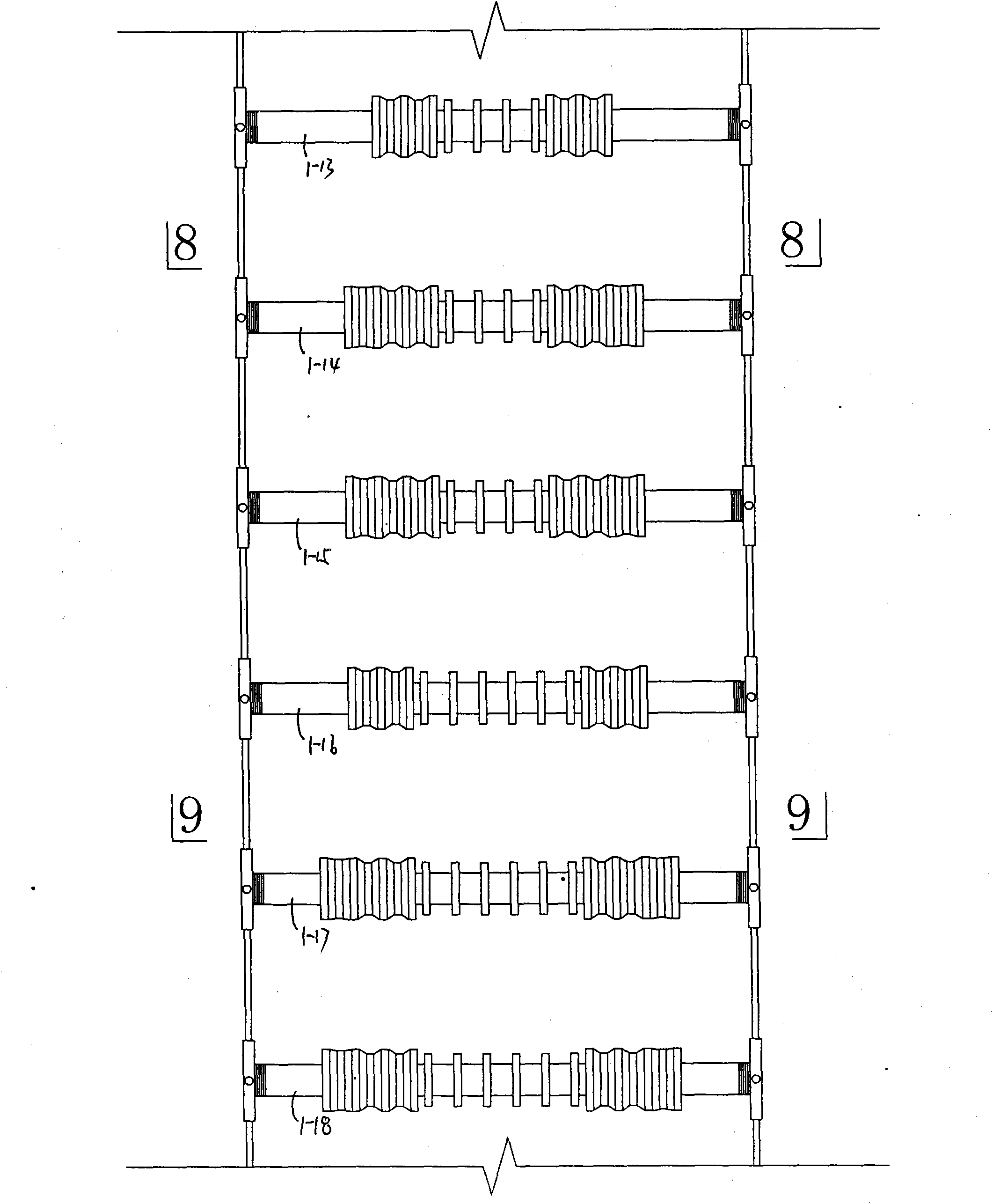

[0034] Embodiment: Referring to the accompanying drawings, the stainless steel honeycomb inclined tube wave plate forming device for water treatment is composed of 31 pairs of concave and convex complementary upper and lower rollers. The upper row of rollers is grooved rollers, and the lower row of rollers is complementary convex active rollers. Among them, there are two sets of wheels in parallel in the first 4 passes, and two sets of wheels are formed in the center of the forming plate, and then a set of wheels are added on the outside in turn, each forming a wave. Each wheel forms a wave symmetrically until the entire width of the plate is formed. Wherein, the aforementioned rolling wheel set and the first wheel set formed by the latter wave are coaxial with the last forming wheel set of the previous forming wave. Each waveform has 4 passes to gradually deepen. The lower wave marks are first rolled out, and the deformation is gradually deepened through the subsequent 3 pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com