Neural network-based grinding machining working condition detection method

A neural network and grinding technology, applied in the field of mechanical processing, can solve the problems of workpiece burn, processing efficiency and quality impact, workpiece and tool damage, etc., to avoid unnecessary damage, improve processing efficiency, and reduce dependence. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

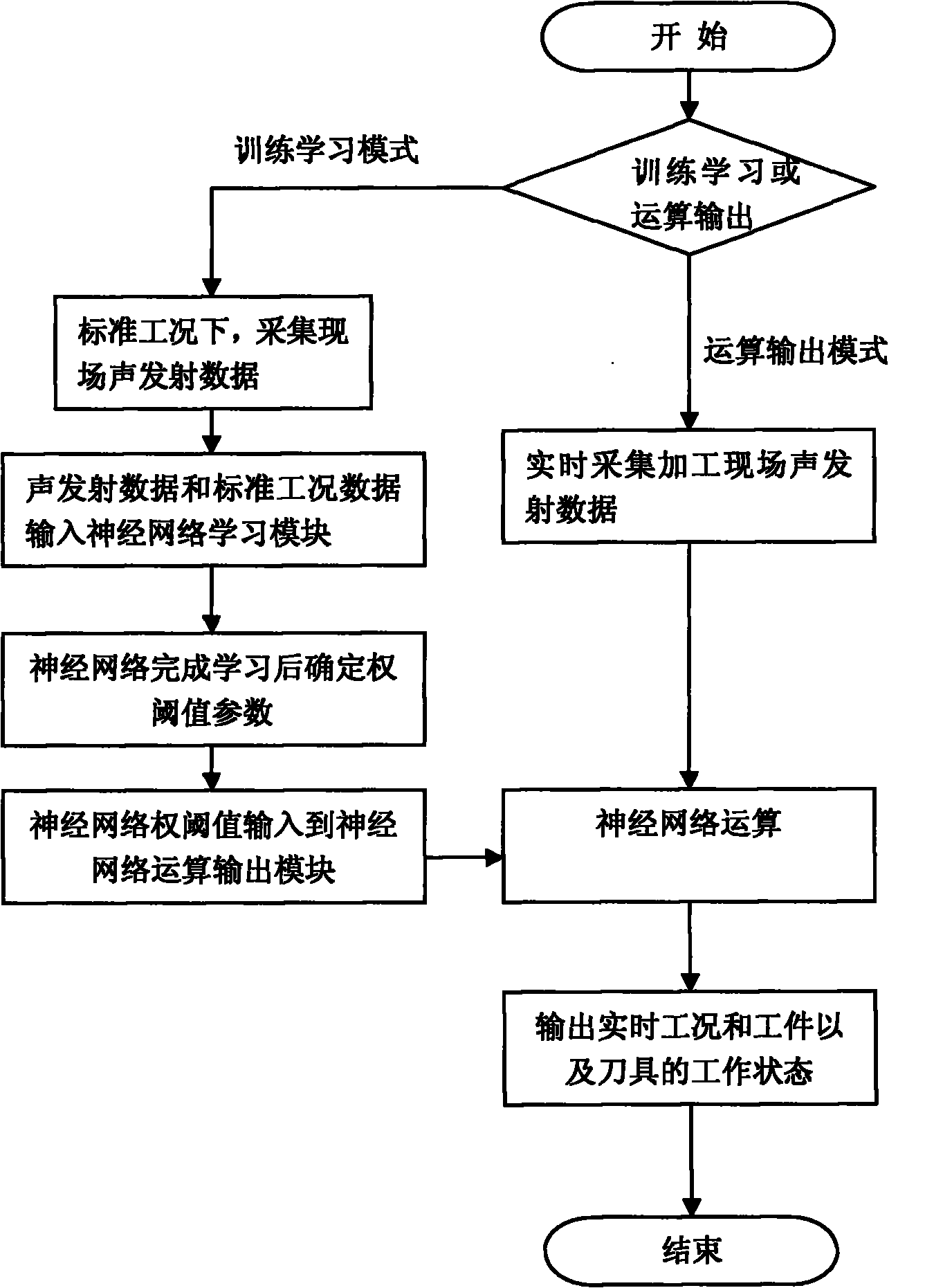

[0038] The present invention will be further explained below in conjunction with the accompanying drawings.

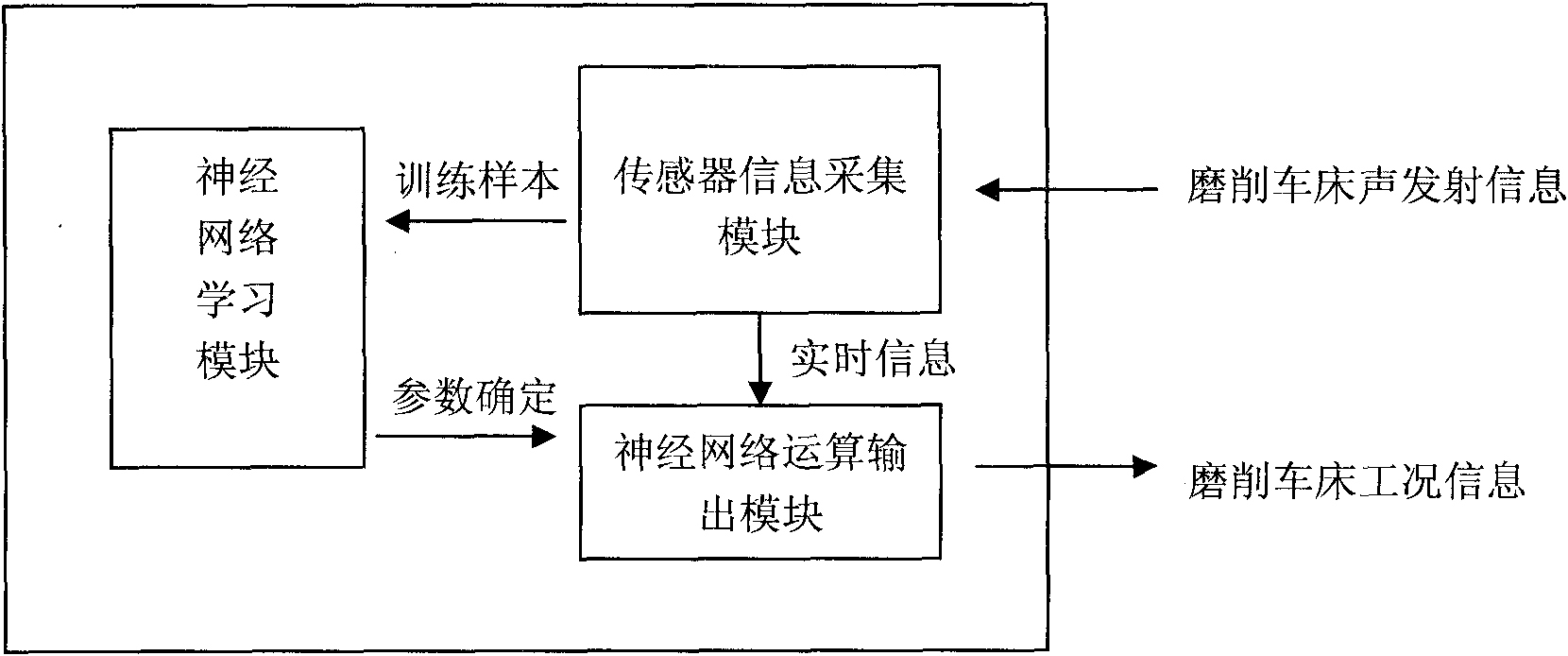

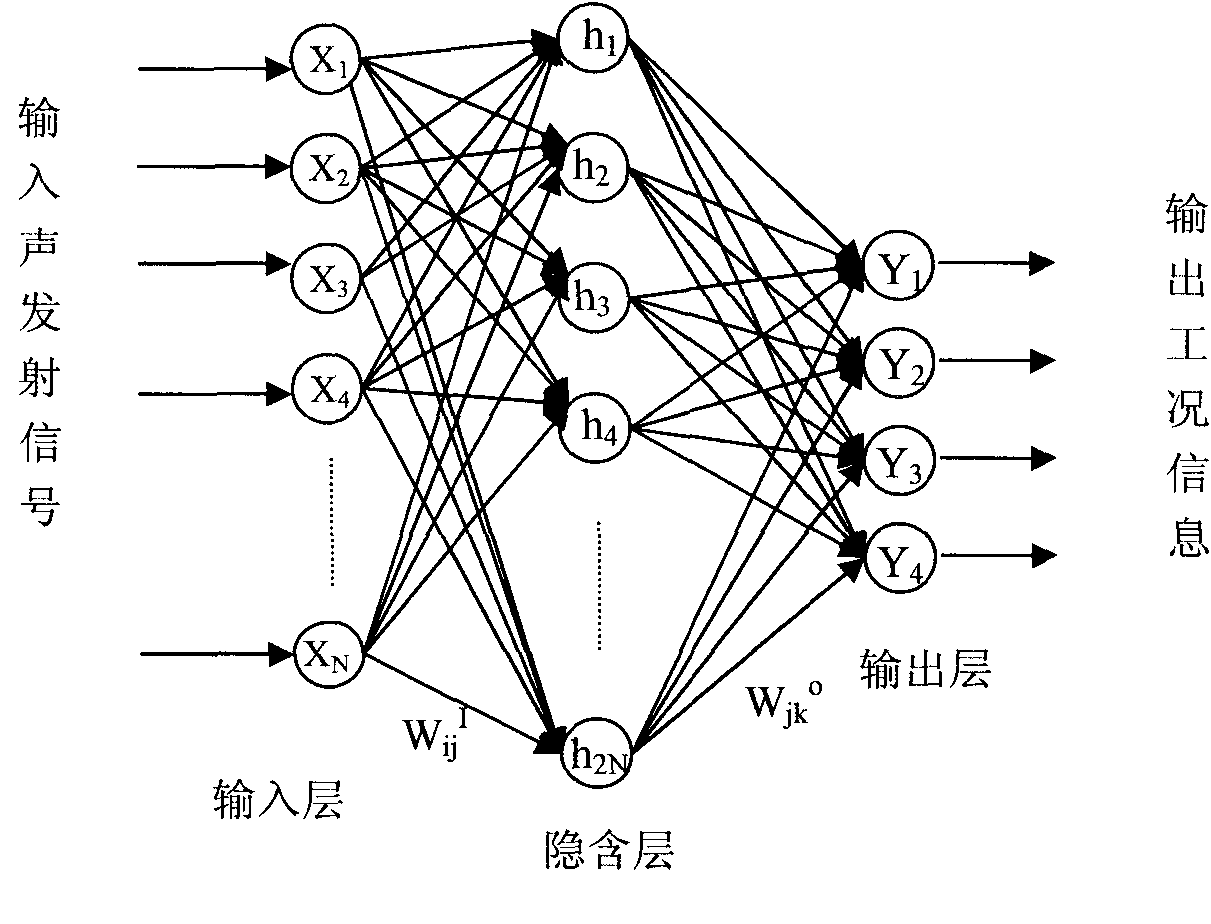

[0039] Such as figure 1 , 2 As shown in and 3, the neural network-based mechanical grinding working condition detection system of the present invention includes a sensor information acquisition module, a neural network learning module and a neural network operation output module.

[0040] The sensor information acquisition module is an acoustic emission sensor, which mainly collects various acoustic emission signals during processing according to a preset sampling frequency.

[0041] The neural network learning module is used to determine the weight threshold parameters of the neural network, and pass it to the neural network operation output module for use. In the learning and training phase, the sample library is formed by collecting the acoustic emission signals when the tool and the workpiece are in contact, the acoustic emission signals when the tool (grinding w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com