Three-plate aluminum alloy forged hub

An aluminum alloy, three-piece technology, applied in the direction of rims, transportation and packaging, vehicle parts, etc., can solve the problems of increasing the weight of the wheel hub, difficulty in adjustment, unsuitable assembly and use, etc., to achieve enhanced mechanical strength, good sealing effect, and concentricity high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

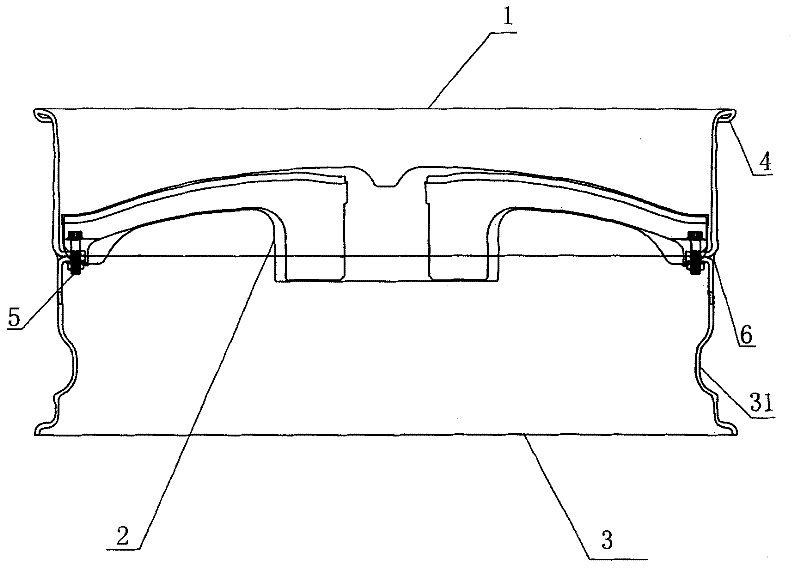

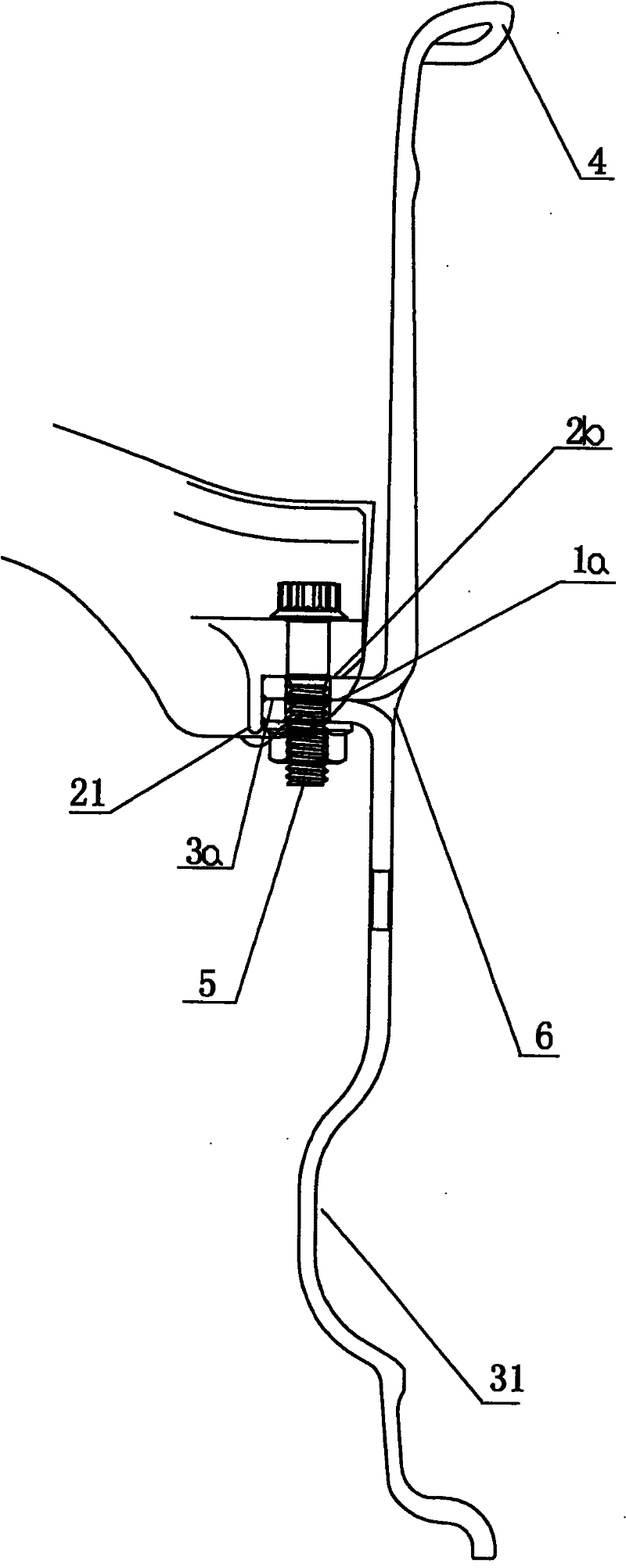

[0021] Figure 1 to Figure 3a Shown is the structural representation of the present invention.

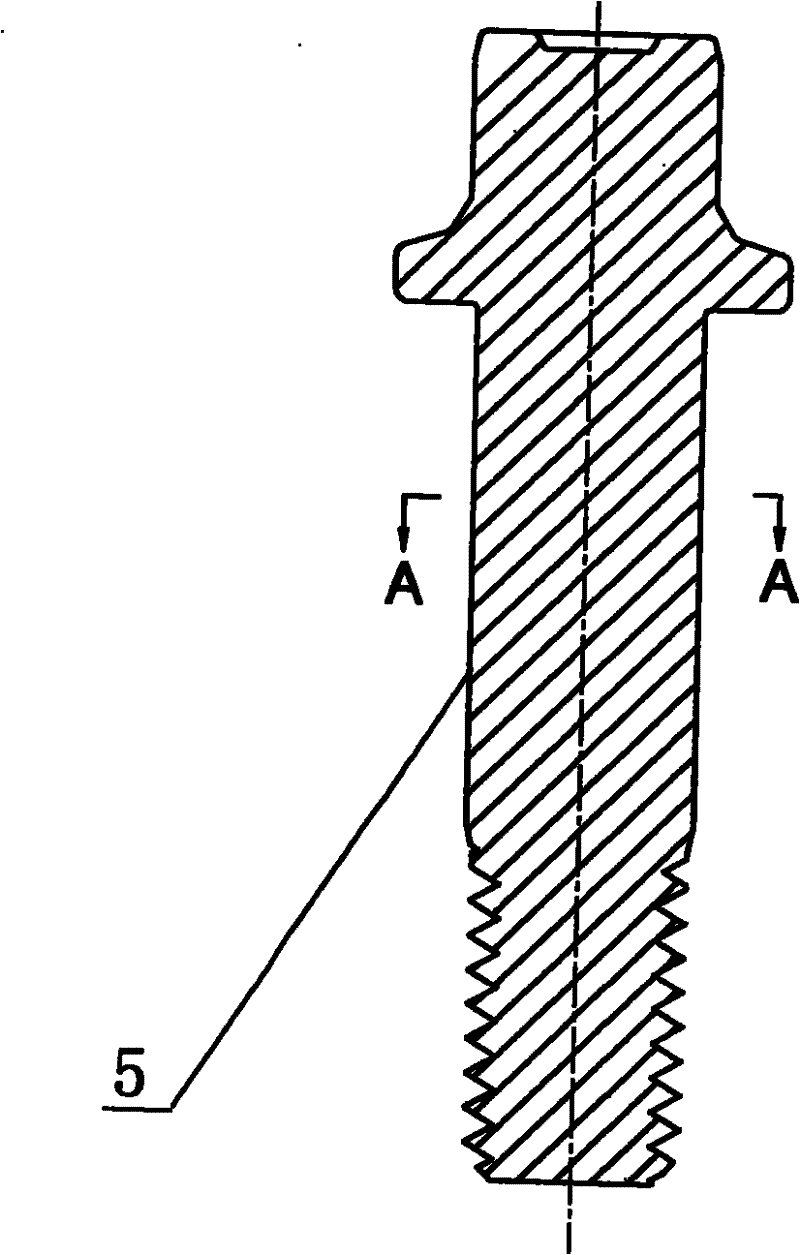

[0022] The reference signs are: rim front piece 1, front piece assembly surface 1a, wheel spoke middle piece 2, middle piece assembly surface 2b, raised rib 21, rim rear piece 3, rear piece assembly surface 3a, fastening bolt 5 , Wheel rim 4, rolling waist 31, anti-skid layer 51, anti-skid rack 51a, rubber sealing layer 6.

[0023] Such as Figure 1 to Figure 3a As shown, a three-piece aluminum alloy forged wheel hub in this embodiment includes a rim front piece 1, a spoke middle piece 2 and a rim rear piece 3; the spoke middle piece 2, rim front piece 1 and rim rear piece 3 adopt The interference fit is assembled and connected by fastening bolts 5, and the spoke middle piece 2 is made with a raised rib 21 that prevents the radial offset of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com