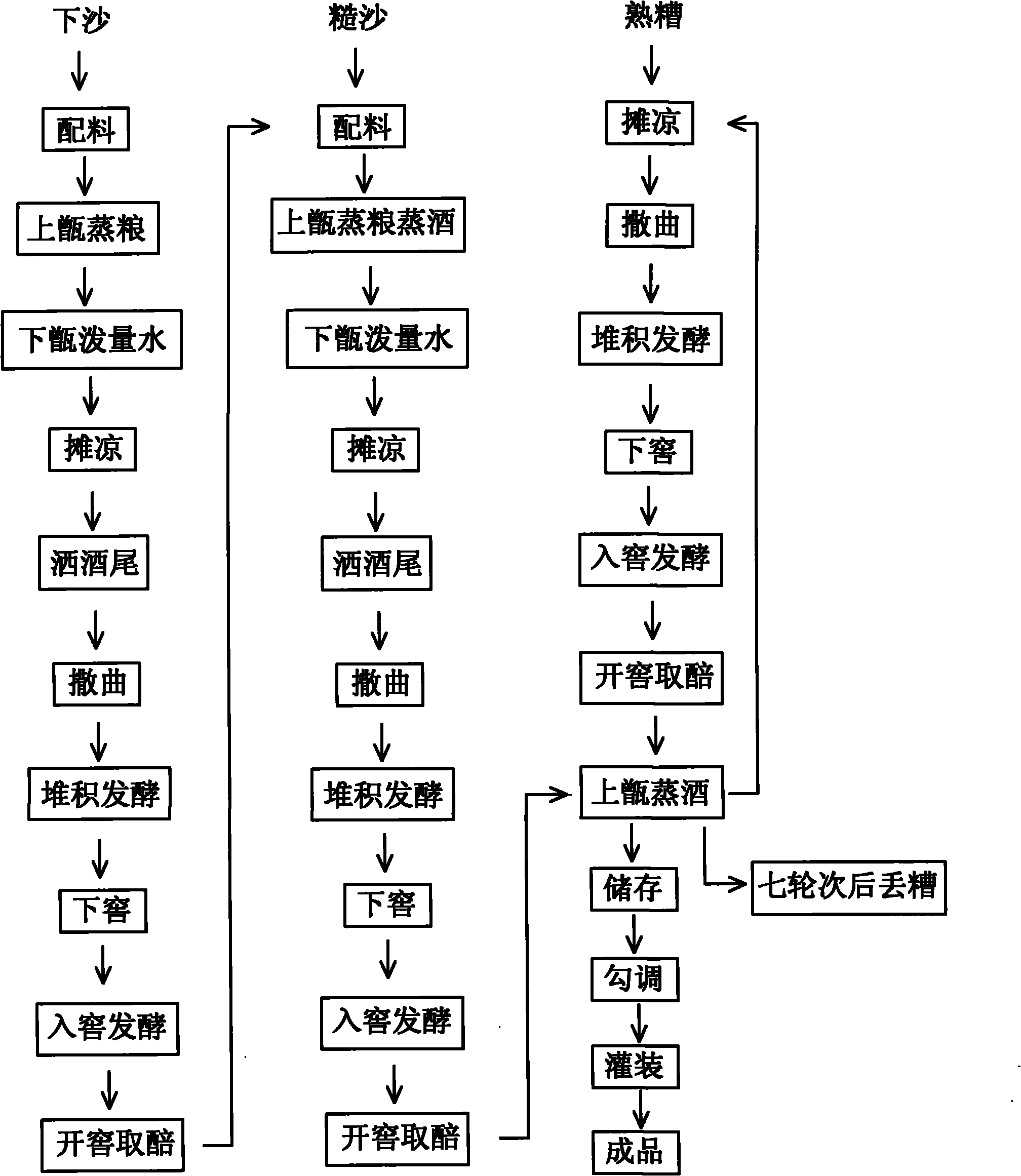

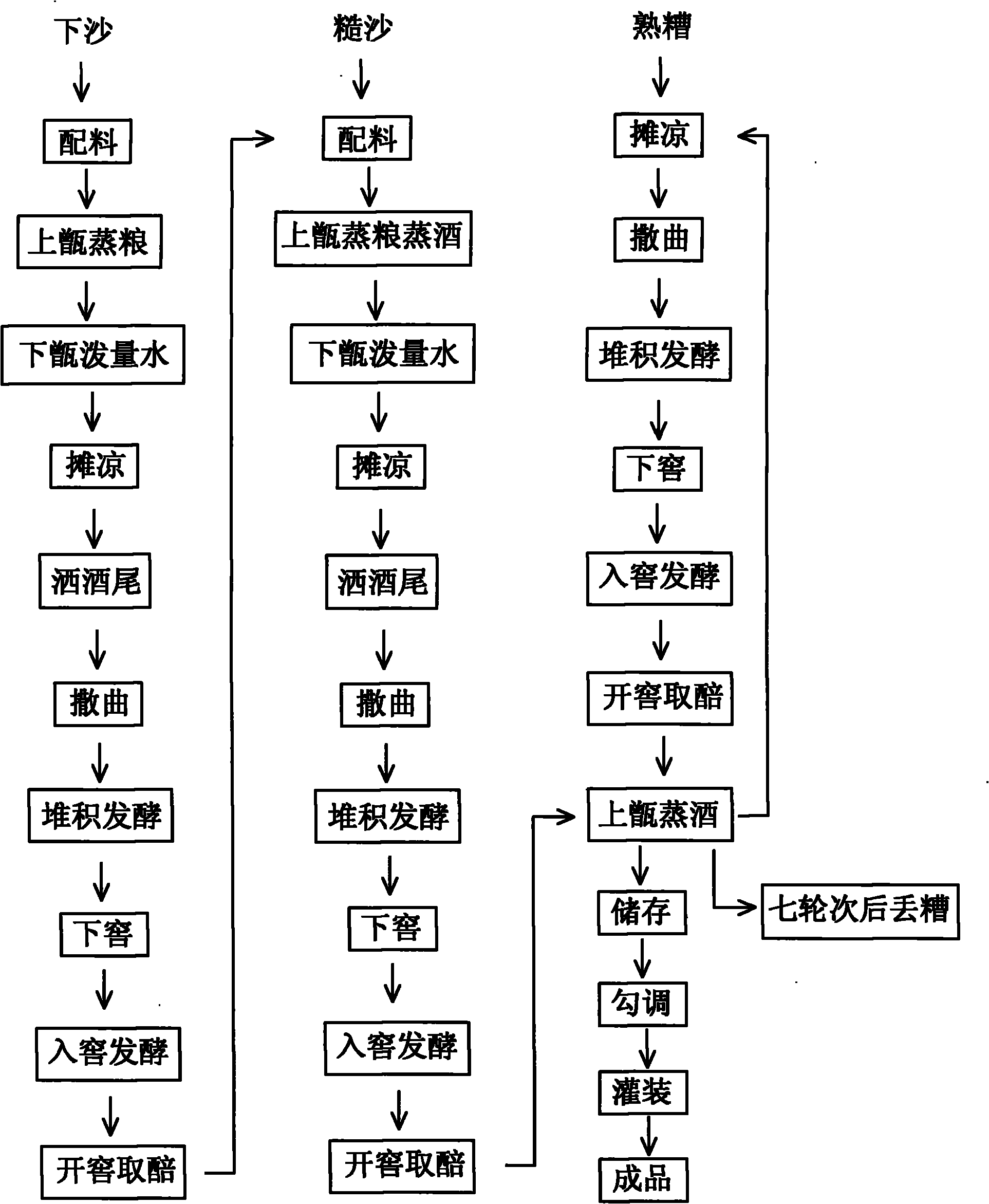

Process of cavern fermented maotai-flavor liquor

The technology of Maotai-flavor liquor and karst cave is applied in the new technological field of brewing Maotai-flavor liquor, which can solve the problems of shortening the aging storage time of Maotai-flavor liquor and shortening the aging period of Maotai-flavor liquor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The process of fermenting sauce-flavored liquor in the karst cave described in the present invention is not repeated for the same part as the traditional production process, and only the different production conditions and processes are explained as follows:

[0082] 1. Environmental conditions for the production of Maotai-flavored high-end liquor:

[0083] Large-scale natural karst caves formed by karst geology, the temperature in the caves is maintained between 18-23°C all year round, the average temperature difference does not exceed 5°C, the highest cave temperature is not higher than 25°C, the lowest cave temperature is not lower than 15°C, and the temperature is relatively maintained Constant, compared with the existing traditional factory buildings, the temperature of the fermentation environment is constant, and the relative humidity in the cave is between 80-90% all the year round. Except for the electric lighting during operation, there is no natural light, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com