Transmission type electrochromic device-based color-changing camouflage fabric and preparation method thereof

An electrochromic and fabric technology, applied in the field of color-changing camouflage fabric and its preparation, can solve the problems of large thickness, low color or electrical conductivity, etc., and achieve the effects of fast change speed, low cost, and convenient production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

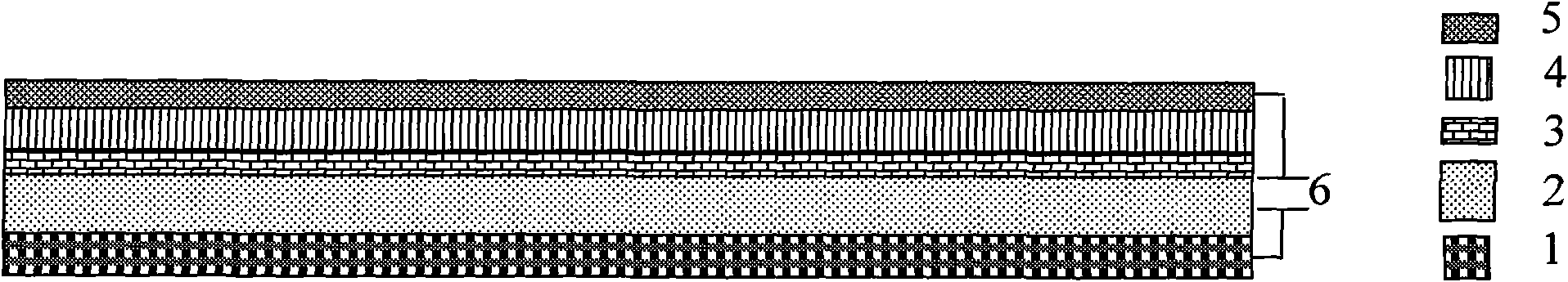

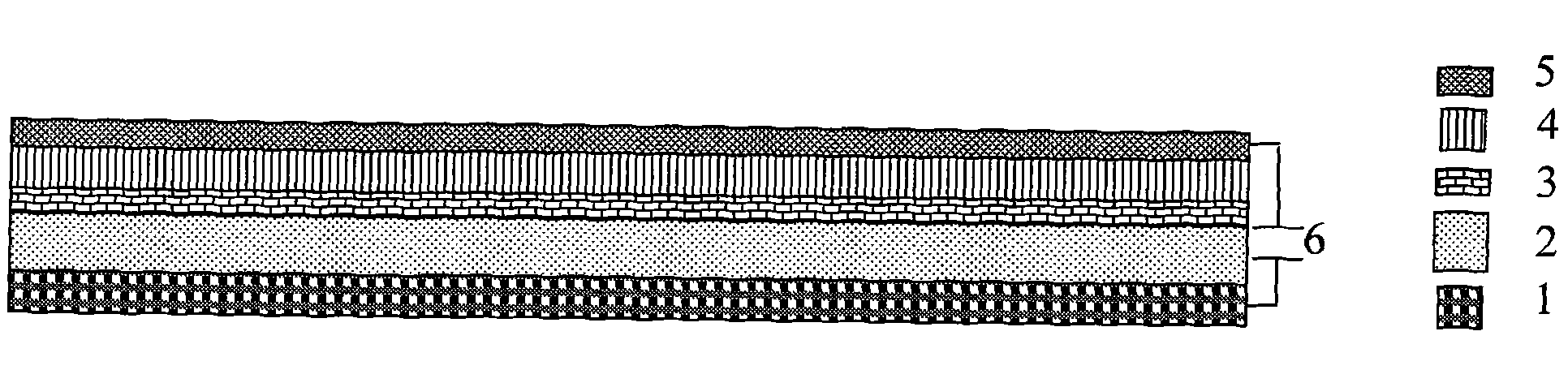

[0054] The invention discloses a preparation method of a color-changing camouflage fabric capable of realizing the interchanging of three camouflage patterns.

[0055] Designed woodland camouflage, desert camouflage and marine camouflage patterns with four-color patches. The woodland camouflage contains four-color patches of green, dark brown, black and light gray, and the desert camouflage contains khaki, dark brown, black and light gray. Four-color patches, marine camouflage includes four-color patches of blue, dark brown, black and light gray. In the three camouflage fabrics, except for the main colors of green, khaki and blue, the other three-color patches are the same in color and shape. Silver fibers and cotton fibers are used as warp yarns, and the silver fibers and cotton fibers are arranged in a ratio of 1:1, and the weft yarns are also woven with silver and cotton in a 1:1 arrangement to obtain a white fabric with a resistivity of 20Ω.cm. The fabric is used as the w...

Embodiment 2

[0063] The preparation method of the color-changing camouflage fabric based on the ZAO-based transparent conductive film, except for the following differences, other preparation steps and materials used are the same as in Example 1.

[0064] Embodiment 1 provides the preparation method of the color-changing camouflage fabric using ITO / PET as the transparent conductive film. Based on the mature preparation technology of PANI, the flexible transparent conductive film electrode is the key factor of the color-changing camouflage fabric.

[0065] The preparation method of the transparent conductive film of described ZAO is as follows: with 100 parts (weight) of the slurry of the uniform dispersion of ZAO, with 8 parts (weight) of hydrochloric acid, 2 parts (weight) of n-butanol and 12 parts (weight) of film-forming agent ) heated and stirred at 50°C to form a uniform, stable and transparent pasty liquid. The liquid was coated on a PET film and dried for 2 hours. The surface resis...

Embodiment 3

[0067] The preparation method of the color-changing camouflage pattern using polythiophene as the electrochromic polymer is the same as in Example 1 except for the following differences.

[0068] Embodiment 1 has provided the preparation method of color-changing camouflage fabric, wherein the electrochromic high polymer adopts polythiophene to replace, and its synthetic process is as follows: 3,4-dioxyethylenethiophene (EDOT) monomer is mixed by molar ratio Add to the PVA1750 solution containing a part of DBSA (PVA mass fraction 2.3%), then add a part of sodium persulfate, stir at room temperature for 10 minutes, gradually add 1.5 parts of a mass fraction of 14% ferric chloride solution, dropwise Reaction after 8-10h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com