Method for measuring residual austenite content in steel

A technology of retained austenite and austenite, which is applied in the field of determination of retained austenite in steel, can solve problems such as inability to complete measurement work, and achieve the effect of eliminating influence and reducing error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

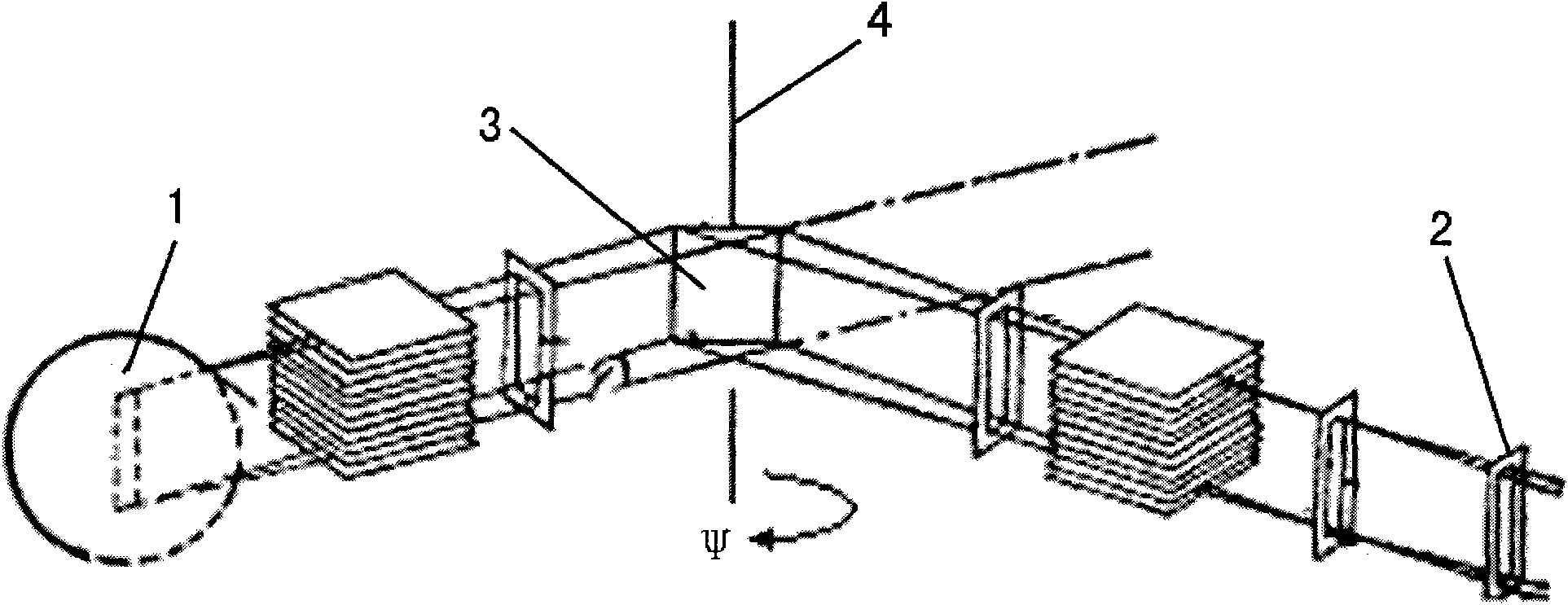

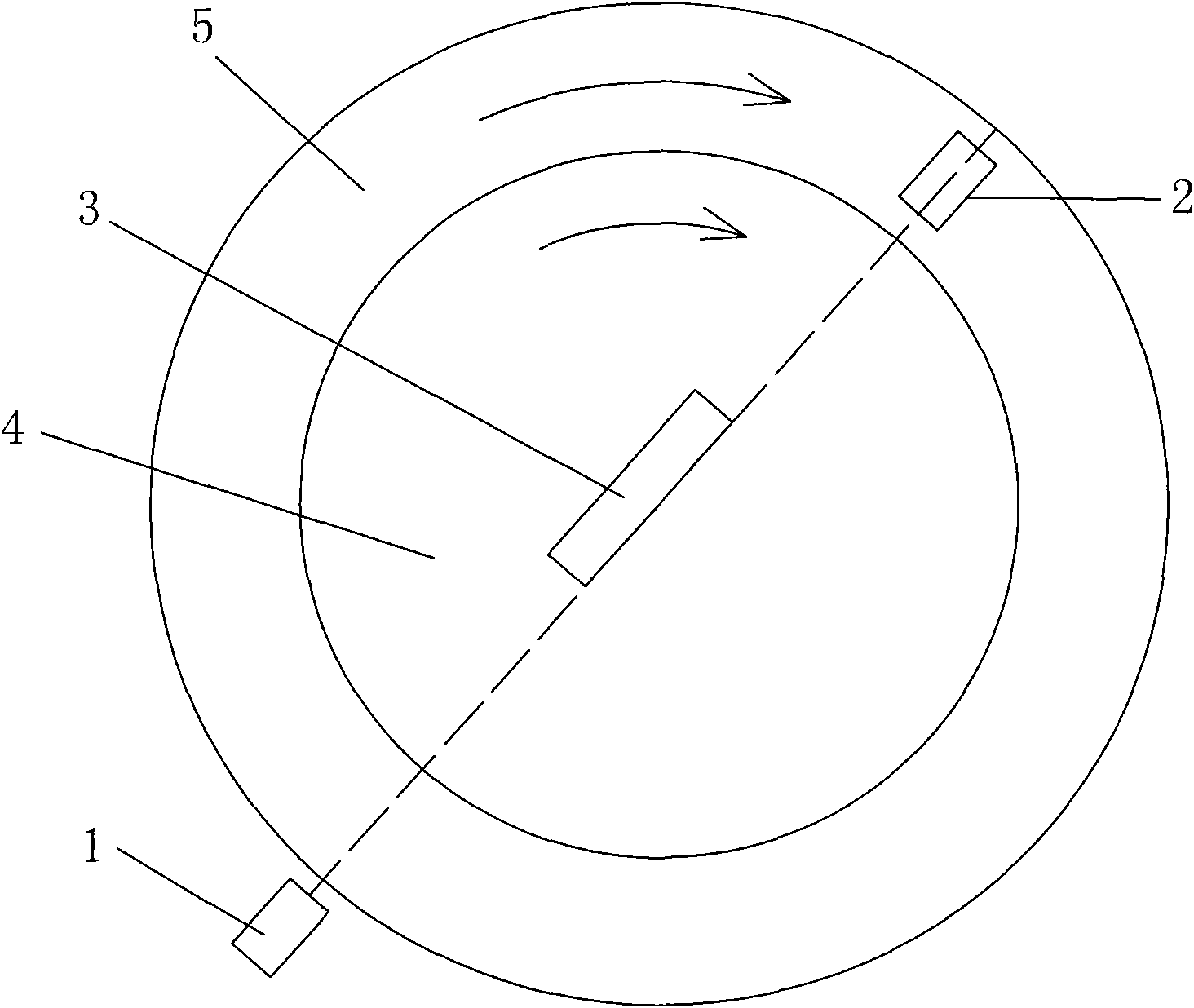

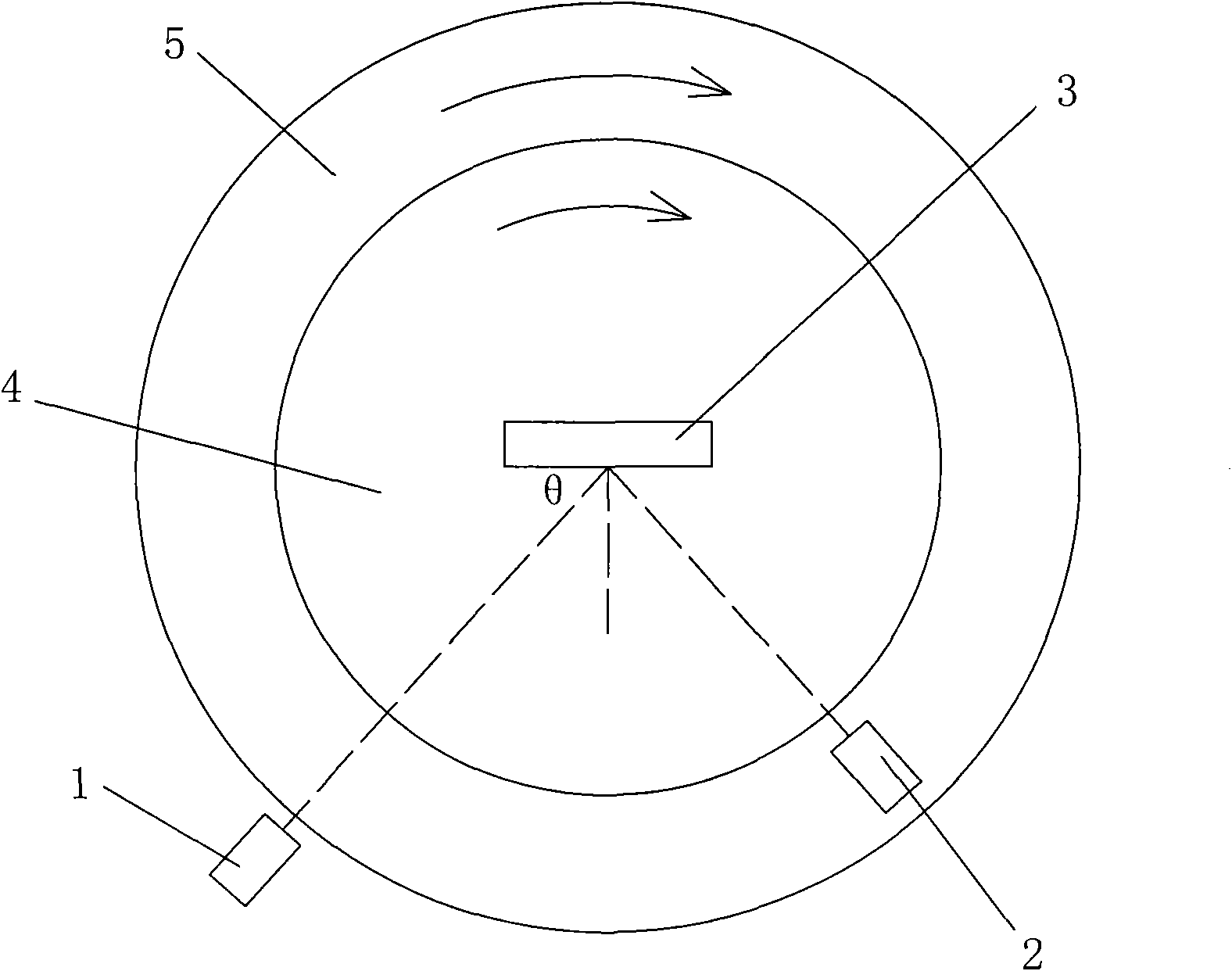

[0059] A method embodiment of the present invention for measuring retained austenite content in steel, its measuring equipment is mainly X-ray diffractometer, such as figure 1 , 2 As shown, the X-ray diffractometer includes a radiation source 1, a detector 2, and a goniometer. The goniometer is composed of a 1θ axis 4 and a 2θ axis 5. The detector 2 is set on the 2θ axis 5, and the sample or standard sample 3 Placed on 1θ axis 4.

[0060] The inventive method comprises the following steps:

[0061] Step (1), before the experimental measurement, first prepare a piece of iron and steel material sample i, which contains austenite (γ phase) and martensite (α phase), or austenite (γ phase) At the same time, a standard sample j of block pure martensite or pure ferrite should be prepared. The physical state and chemical composition of standard sample j and sample i should preferably be the same or similar. There is no texture in j, the test sample i and the standard sample j are m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com