Method for interactively designing differential fiber spinning process based on data drive

A data-driven, design method technology, applied in the field of fiber production, which can solve problems such as slow convergence speed and difficulty

Inactive Publication Date: 2010-09-01

DONGHUA UNIV

View PDF3 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the limitations of IGA limit its application and promotion. Its shortcomings: first, the convergence speed is too slow, and second, it requires too much participation of experts

It is precisely because of the ambiguity and randomness brought about by these factors that it is very difficult to design an optimized production process for a specific fiber and determine the optimized production index and process parameters.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

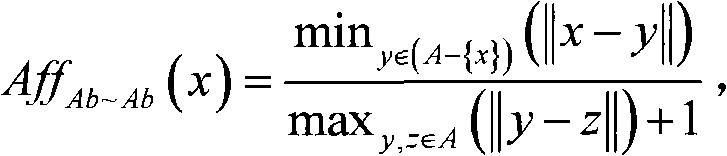

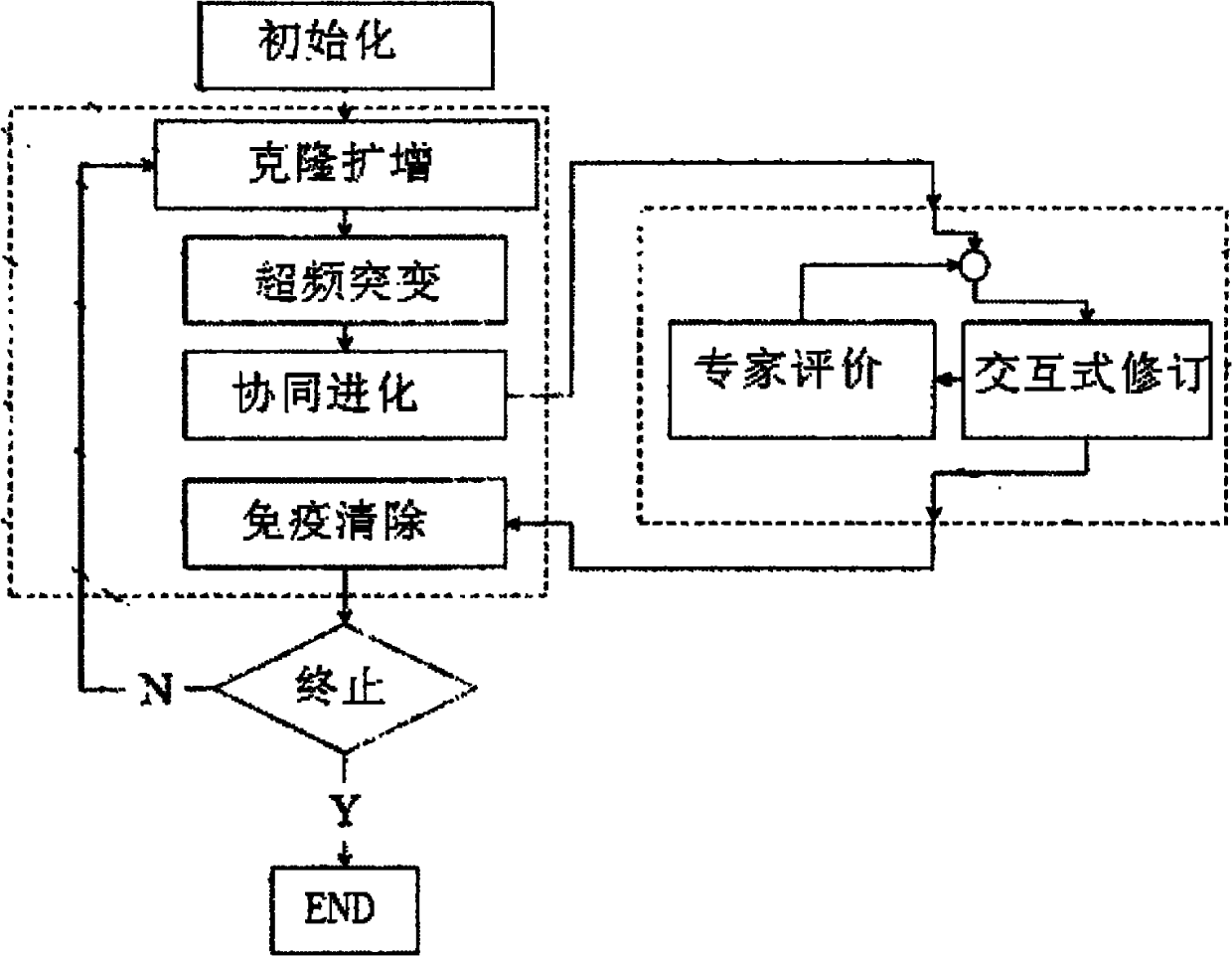

The invention provides a method for interactively designing a differential fiber spinning process based on data drive, which comprises the following steps of: first performing initialization to generate an antibody population and antigens and generating an initial population randomly or by using schemes initially designed by process designers; then evolving the antibody population by using an immune evolution operator so as to realize the most likely matching of the antigens, and giving performance evaluation values to each designed scheme by using a scheme evaluation module by process designing experts in the realization of the matching, or giving suggestions on improvement for shortcomings in the schemes at the same time of giving the evaluation values; and finally judging whether the evolution is finished or not according to the evaluation suggestions of the process designing experts in alternatives and in combination with degree of approximation between superior historical schemes stored in an expert system and a current alternative, if the evolution is finished, quitting, and if the evolution is not finished, repeating each step in the optimizing method of the invention. The method has the advantages that: 1, an interactive intelligent spinning process optimizing model is established to provide basis for the setting of production parameters; and 2, the spinning process expert system is adopted to analyze and evaluate a result set and guide production, and a knowledge base and a rule set of the expert system can be continuously added and improved, so the system has a self-learning function.

Description

technical field The invention belongs to the field of fiber production, and in particular relates to a data-driven interactive intelligent optimization design method for spinning process for differentiated fibers. Background technique Fiber production (including natural fiber, polymer fiber, etc.) is a large-scale production system with multiple production links and complex production conditions. The realization of the monitoring and control of the production process requires the combination of understanding and modeling of production equipment and production technology , as well as the design and optimization of the production line control system. For fiber production simulation technology, its core is the accurate description and calculation of forming mechanism, equipment status and engineering status. In terms of fiber forming mechanism, since the 1960s, Ziabicki, Gagon & Denn, Geoge and others have done a lot of basic theoretical research work on the spinning process, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G05B13/02

Inventor 丁永生王华平梁霄李莺莺郝矿荣任立红

Owner DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com