Continuous countercurrent flow obstruction rod extractor

A technology of baffle tubes and extractors, which is applied in the direction of solid solvent extraction, etc., can solve the problems of increasing equipment materials and cost, inconvenient disassembly and washing, and insufficient compactness, so as to save heat and kinetic energy, less solvent dosage, and easy cleaning Time-saving and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

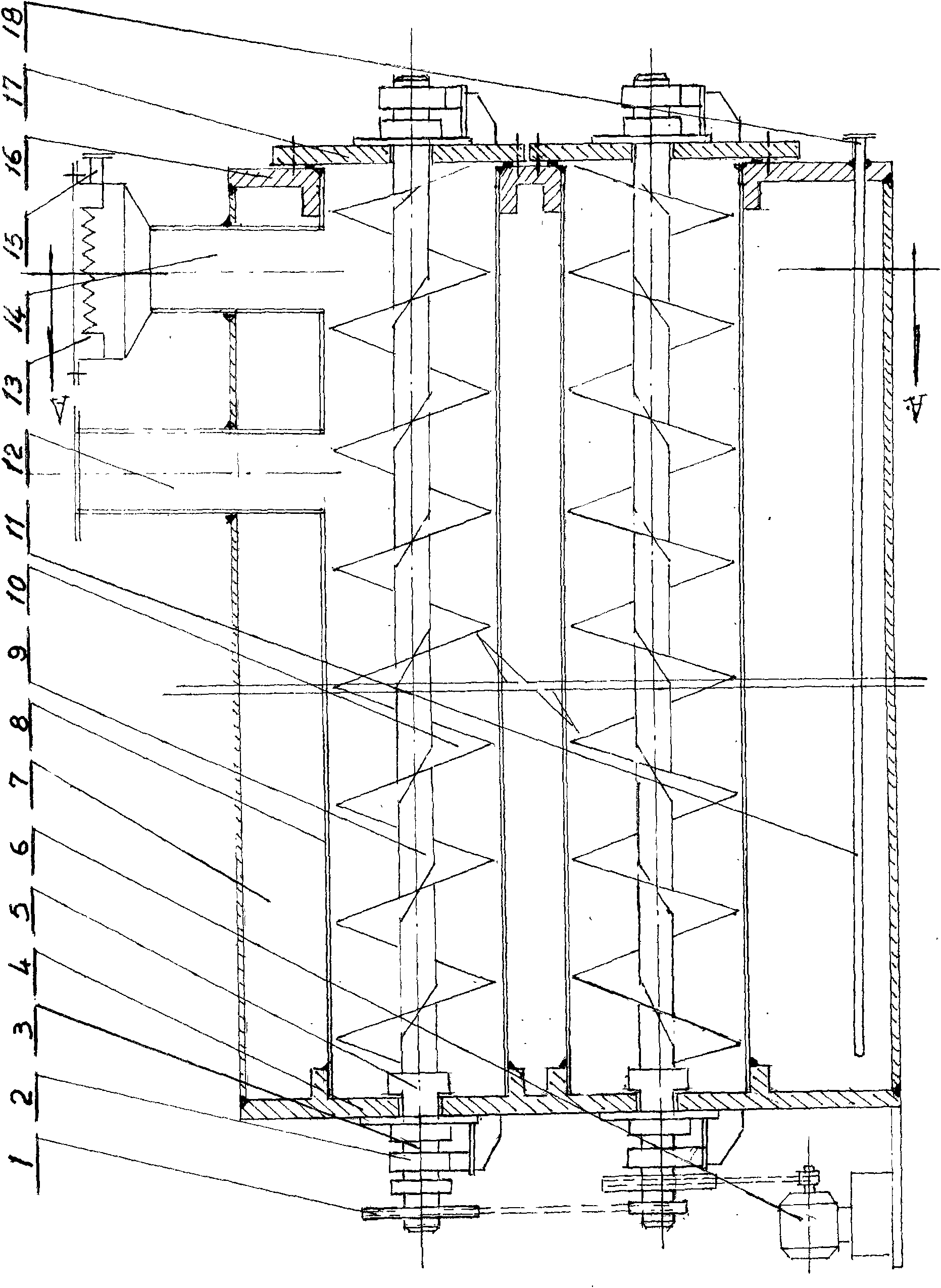

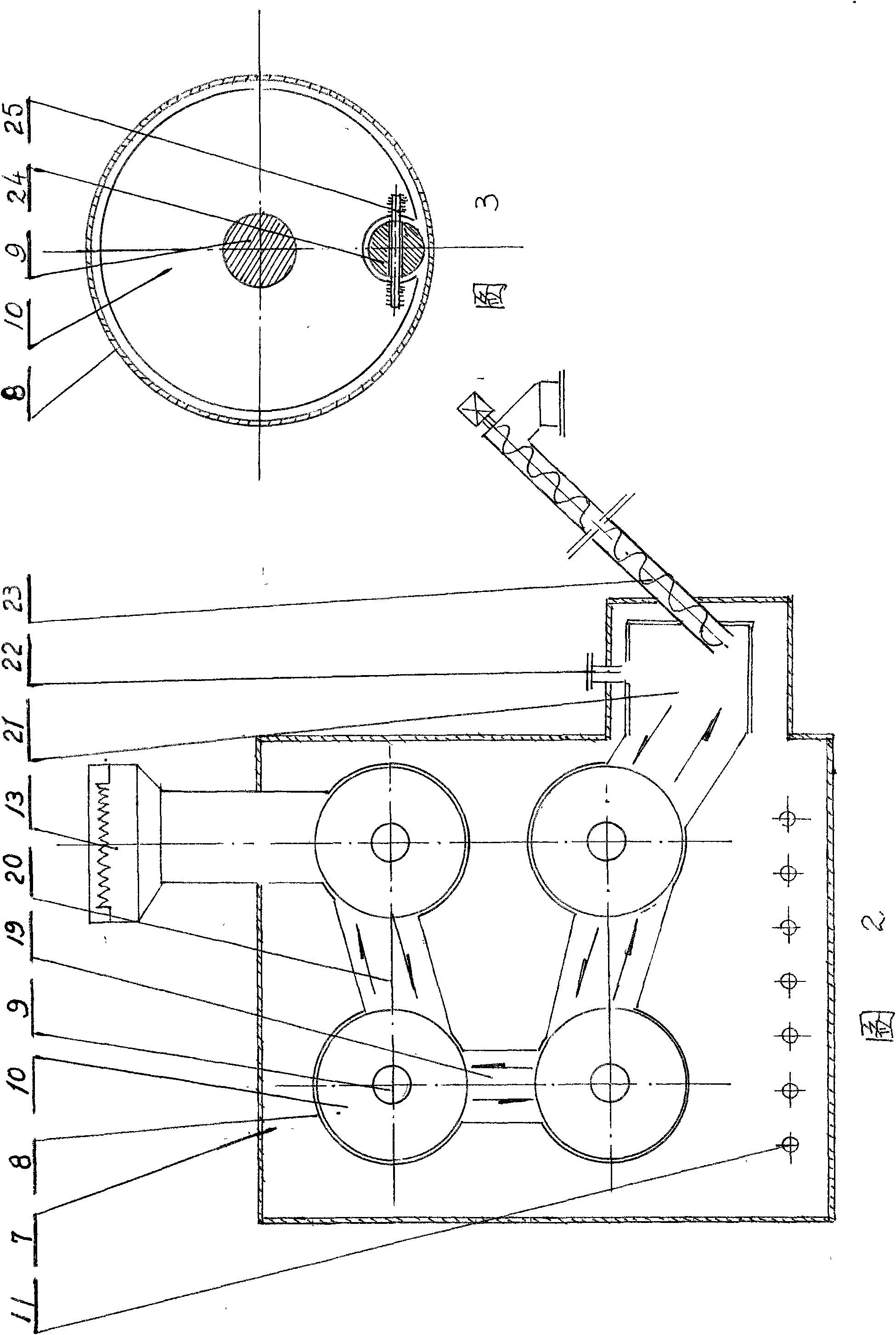

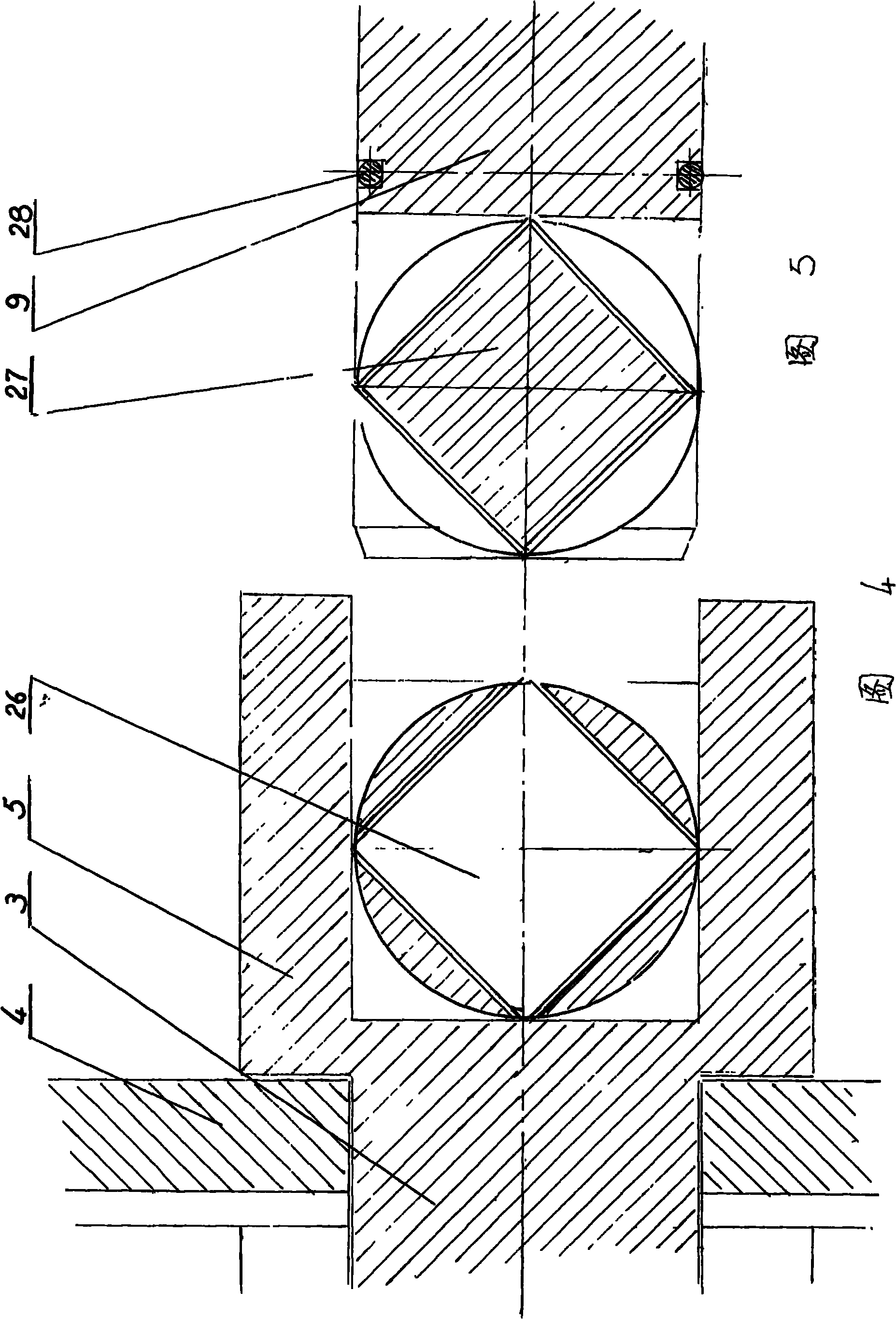

[0011] Embodiments of the present invention are further described in conjunction with the accompanying drawings, figure 1 , the continuous countercurrent baffle tube extractor shown in 2 includes a drive sprocket (1), a shaft support (2), a drive shaft (3), a left fixed support plate (4), a shaft joint (5), a drive machine (6), low-temperature steam generator (7), extraction pipe (8), screw shaft (9), screw pusher (10), heating evaporation coil (11), medicinal material inlet (12), gear shaped overflow tank (13), extraction liquid outlet pipe (14), extraction liquid outlet (15), right fixed support plate (16), screw shaft detachable support plate (17), heating steam inlet (18), extraction pipe Vertical connection pipe (19), extraction pipe inclined connection pipe (20), waste residue tank (21), solvent inlet (22) and spiral slag discharger (23) etc. are formed. It is characterized in that two or more extraction tubes (8) at both ends are welded to the left and right fixed supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com