Heavy oil cracking catalyst and preparation method thereof

A technology of heavy oil cracking and catalyst, applied in the field of heavy oil cracking catalyst and its preparation, which can solve the problems of poor metal resistance and low percentage of heavy oil cracking catalyst, and achieve the effect of excellent metal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

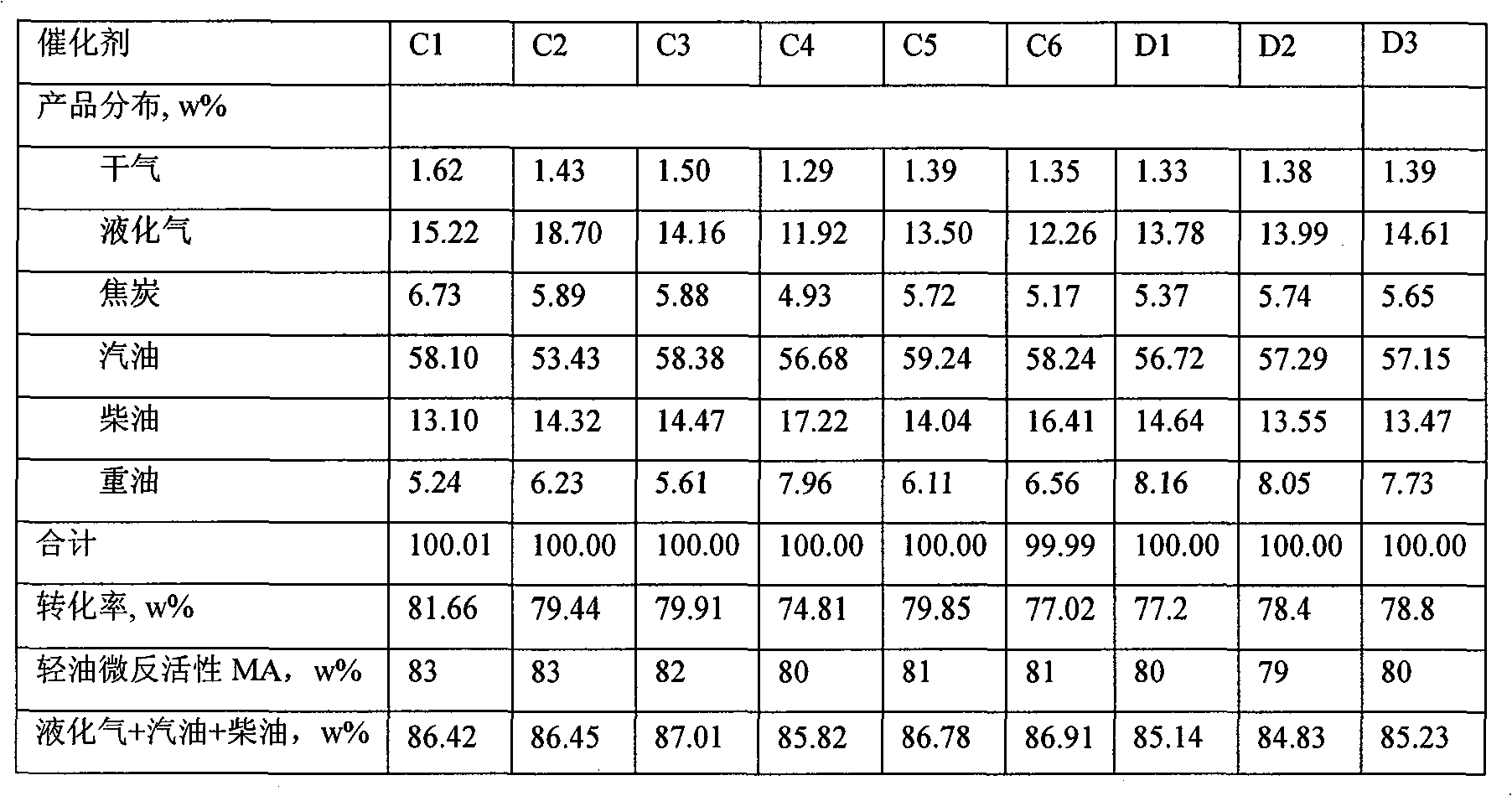

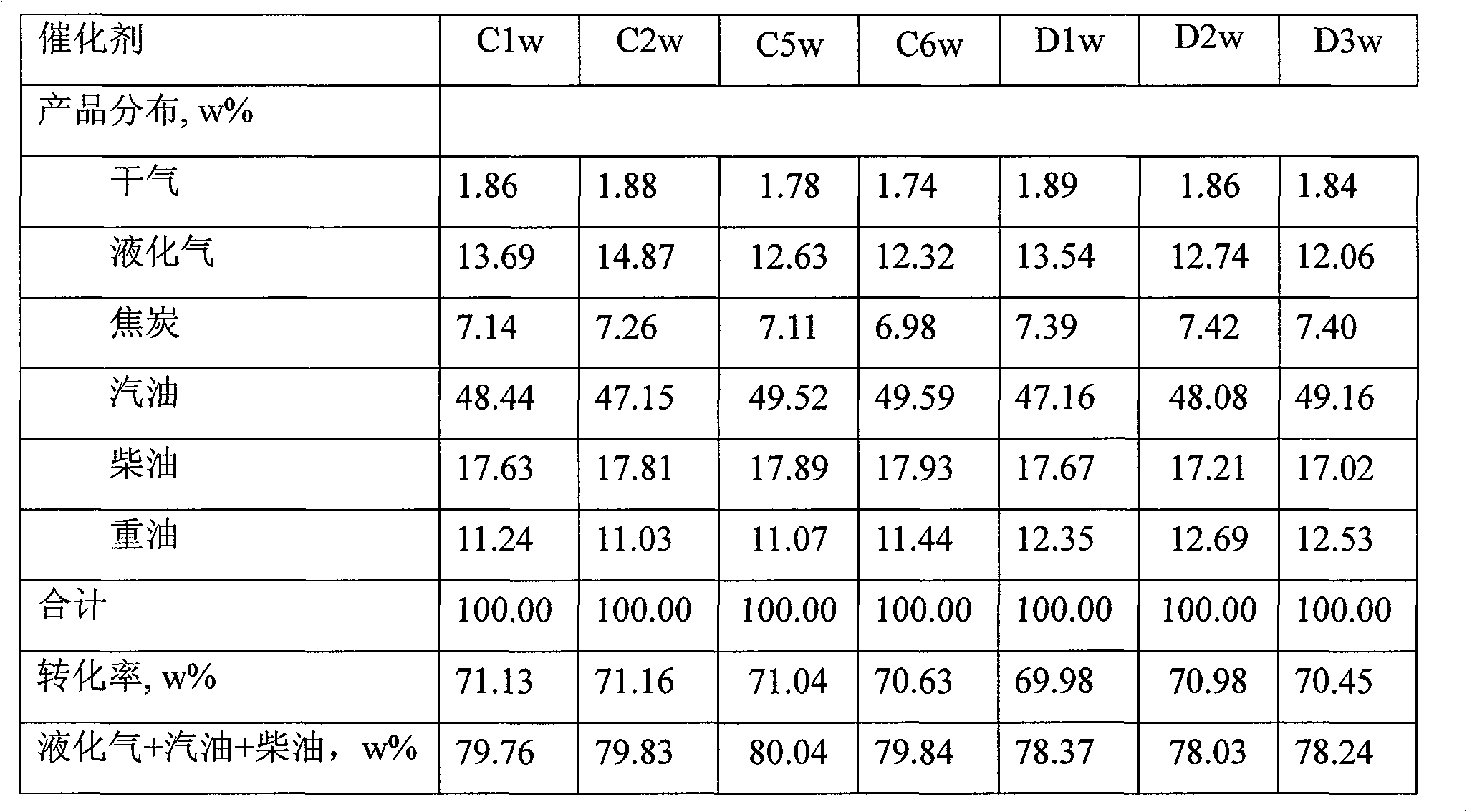

Examples

preparation example Construction

[0024] The invention provides a kind of preparation method of catalyst, this method comprises:

[0025] Mix retort earth, additives, water and inorganic acid for beating, and keep it for more than 30 minutes, preferably 30-120 minutes, to prepare the first slurry, wherein the amount of water is such that the solid content of the obtained first slurry is 10- 60% by weight, and the consumption of retort earth and auxiliary agent makes rector earth: the weight ratio of auxiliary agent in terms of elements is 80-99.9: 0.1-20, and described auxiliary agent is the compound of Co, the compound of Zn and the compound of Cu One or more of the compounds, or a mixture of one or more of the compounds of Co, Zn and Cu with La compounds and / or Ti compounds;

[0026] mixing and beating the first slurry with zeolite, heat-resistant inorganic oxide and / or its precursors to prepare a second slurry, or drying the first slurry, and mixing the dried product with zeolite, water, and heat-resistant ...

Embodiment 1

[0039] In 16.7 kilograms of decationized water, add 11.3 kilograms of retort earth under stirring conditions, after stirring for 15 minutes, add 179 grams of chemically pure hydrochloric acid for acidification, continue stirring for 30 minutes, add 851 grams of cobalt nitrate (Co(NO 3 ) 3 ·6H 2 O, produced by Beijing Chemical Reagent Company), after stirring for 60 minutes, a slurry with a solid content of 35% by weight was obtained, which was T1.

Embodiment 2

[0041] In 12.7 kg of decationized water, add 912 g of lanthanum chloride (same as above), 100 g of titanium dioxide (produced by Beijing Chemical Reagent Company) and 314 g of copper sulfate (CuSO 4 ·5H 2 (O Beijing Chemical Reagent No. 3 Factory production), after stirring for 10 minutes, add 10.9 kilograms of retort earth, after stirring for 30 minutes, add 48 grams of chemically pure hydrochloric acid to carry out acidification treatment, after stirring for 60 minutes, the obtained solid content is 40% by weight The slurry is T2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com