Method for controllably synthesizing bismuth-based nano-material by directly electrolyzing metal bismuth

A technology of nano-materials and metals, which is applied in the field of controlled synthesis of bismuth-based nano-materials from metal bismuth by direct electrolysis, to achieve the effects of increasing bismuth content, cheap and easy-to-obtain raw materials, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

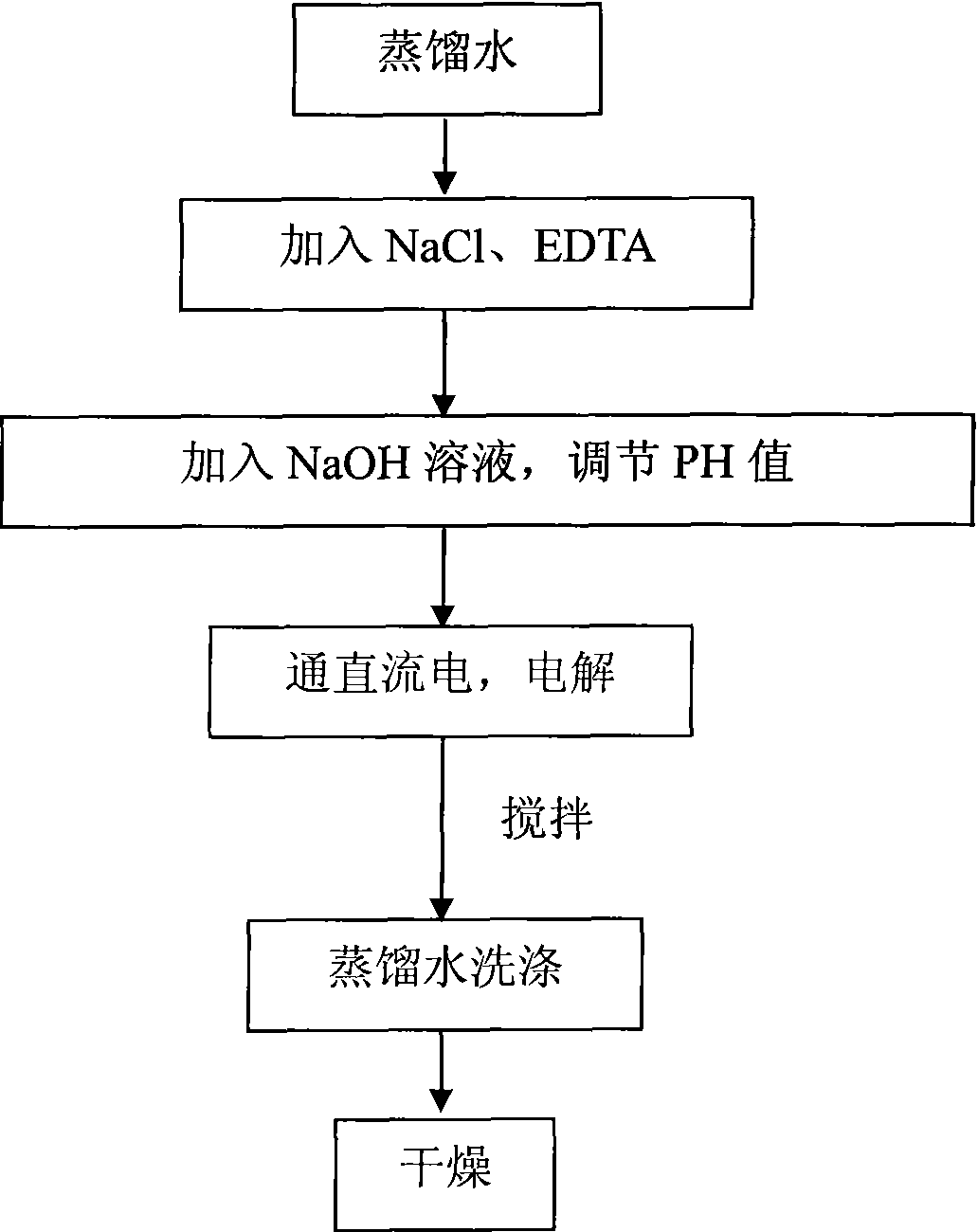

Method used

Image

Examples

Embodiment 1

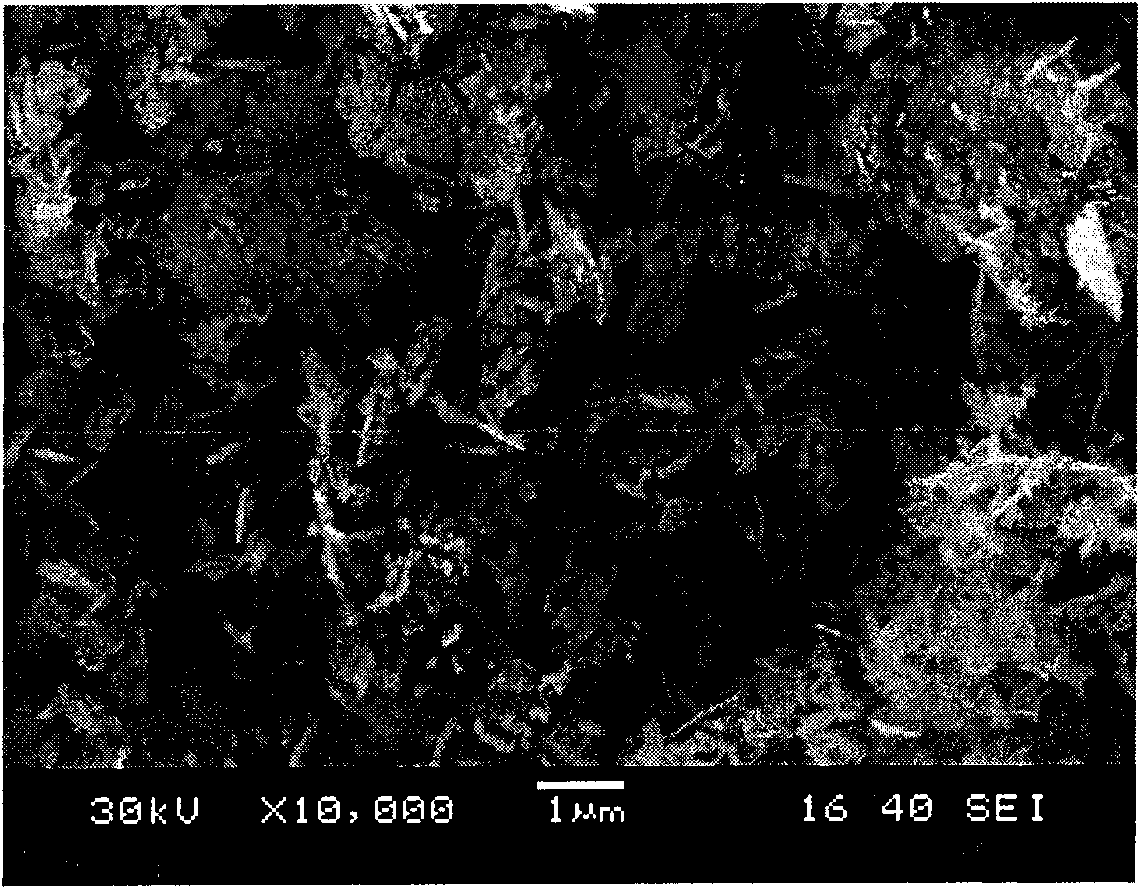

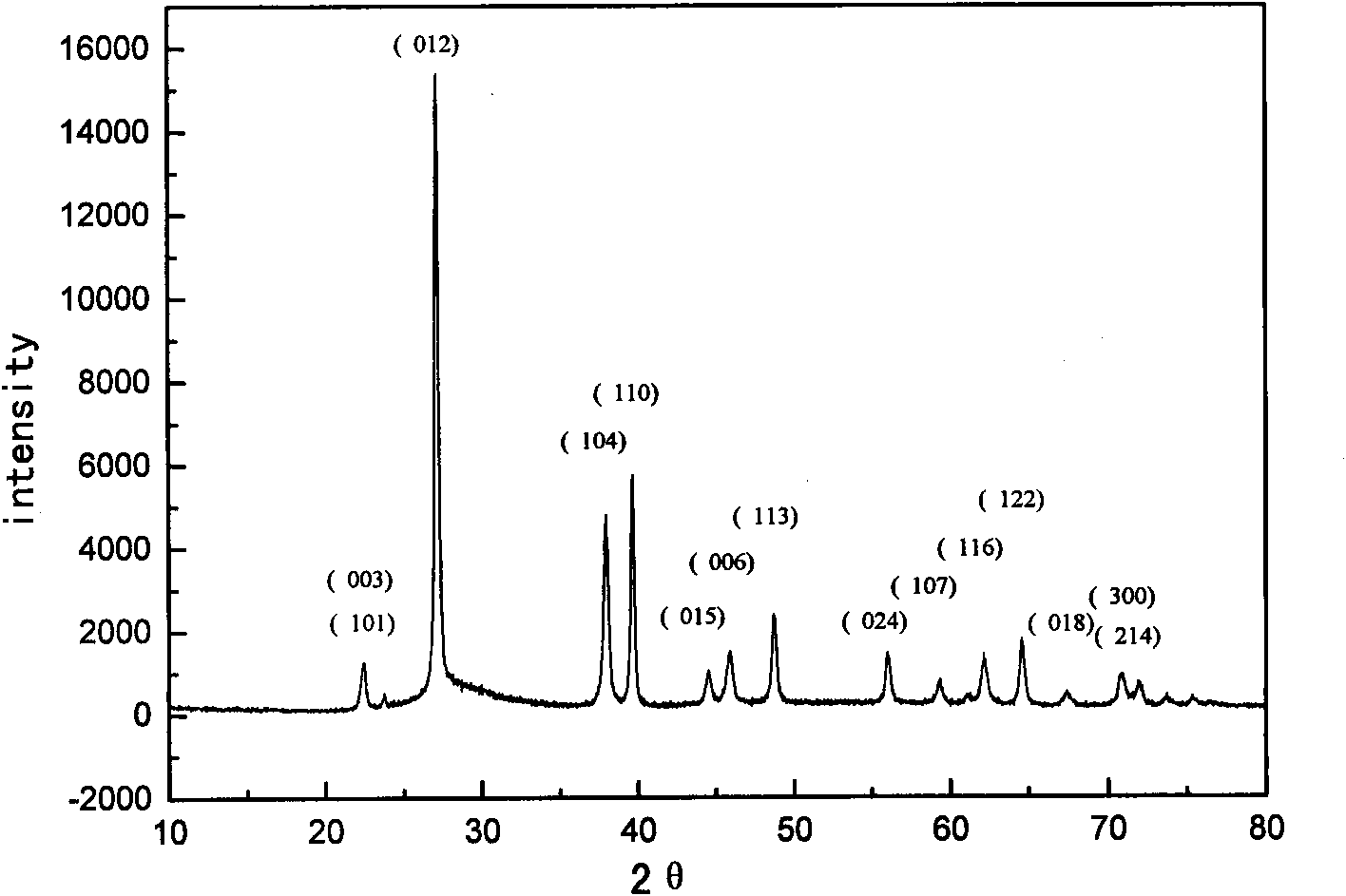

[0025] Take 0.05 mol of commercially available analytical pure NaCl and 0.02 mol of commercially available analytically pure EDTA in a beaker, add 100 ml of distilled water to stir and dissolve, and further adjust the pH to 8 with an aqueous NaOH solution prepared with commercially available analytically pure NaOH. Connect to a DC power supply, use metal bismuth as the anode to corrode the electrode, pass through the DC current, the voltage is 10V, and electrolyze for 2 hours, and the spongy metal bismuth is precipitated at the cathode. The black spongy metallic bismuth is taken out, add 20ml distilled water, stir strongly 20min, filter, dry, obtain 0.4472g black powder, this powder is passed through SEM (such as figure 2 shown), XRD (as image 3 Shown) analysis, this black powder is Bi nano sheet.

Embodiment 2

[0027] In the electrolyte of case 1, continue to add dropwise NaOH aqueous solution prepared with commercially available analytical pure NaOH to adjust PH=10, connect to a DC power supply, use metal bismuth as an anode to corrode the electrode, connect DC with a voltage of 10V, and electrolyze for 4 hours. A large amount of pale yellow precipitate appeared. This pale yellow precipitate was taken out and washed with 20ml distilled water, filtered, dried to obtain 0.8651g yellow powder, this powder was passed through SEM (as Figure 6 shown), XRD (as Figure 7 Shown) analysis, the yellow powder is Bi 24 o 31 Cl 10 Nano powder.

Embodiment 3

[0029] Continue to add dropwise 5mol / L NaOH aqueous solution prepared with commercially available analytical pure NaOH to the electrolyte of Case 2 to adjust the pH to 13, connect to a DC power supply, use metal bismuth as the anode to corrode the electrode, connect DC with a voltage of 10V, and electrolyze for 2 hours , a large amount of yellow precipitate appeared in the solution. This yellow precipitate was taken out and washed with 20ml distilled water, filtered, and dried to obtain 0.4211g yellow powder, which was passed through SEM (as Figure 8 shown), XRD (as Figure 9 Shown) analysis, the yellow powder is Bi 2 o 2.33 Nanosheets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com