Waterproof sandwich material

A technology of interlayer material and modified asphalt, which is applied in the direction of roads, pavement details, roads, etc., can solve the problems that building waterproof interlayer membranes are difficult to meet the requirements, and achieve tight interlayer bonding, high bonding strength, and good temperature resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The asphalt used for the waterproof interlayer material is selected, and the asphalt has excellent high temperature stability and low temperature deformation resistance. The modifier used is styrene-butadiene-styrene block copolymer (SBS), and the addition amount is 6%. High-speed shearing method was used for indoor test, and colloid mill was used for production on site. The SBS used in this example is produced by Yueyang Petrochemical General Plant.

[0031] According to the preparation method of existing waterproof interlayer material, above-mentioned modified bitumen is coated on 160g / m 2 The polyester filament tire base cloth is used to obtain a waterproof interlayer material provided by the present invention after cooling. The thickness of the modified asphalt is 0.1cm.

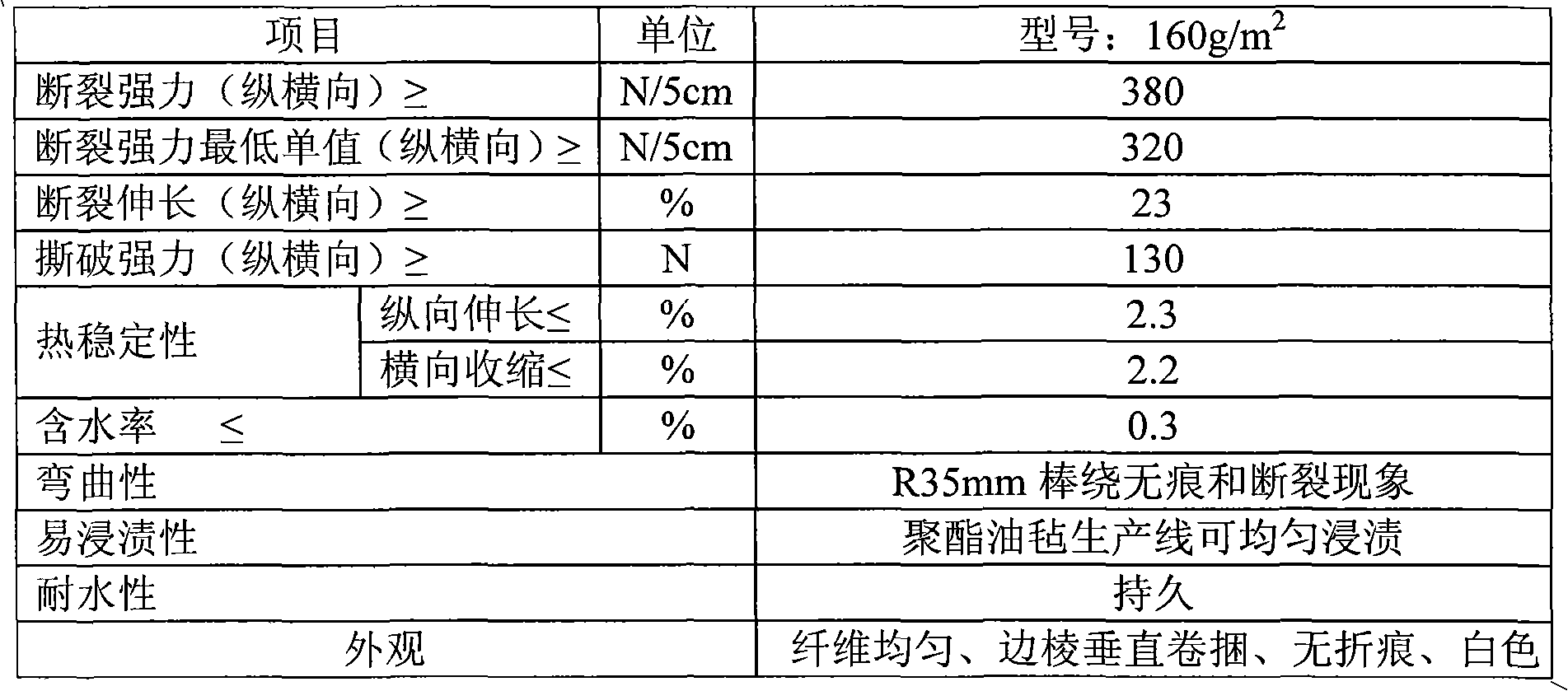

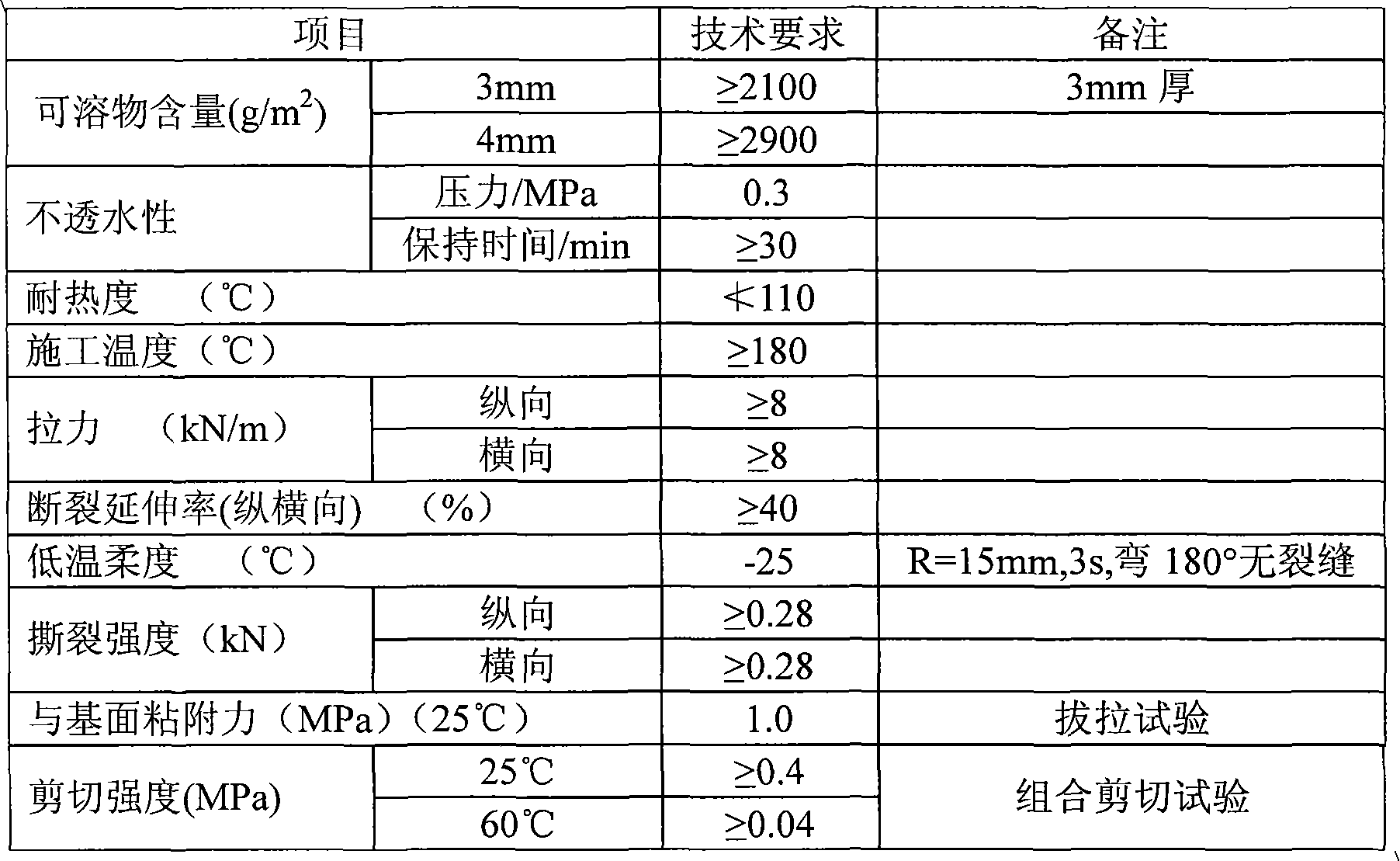

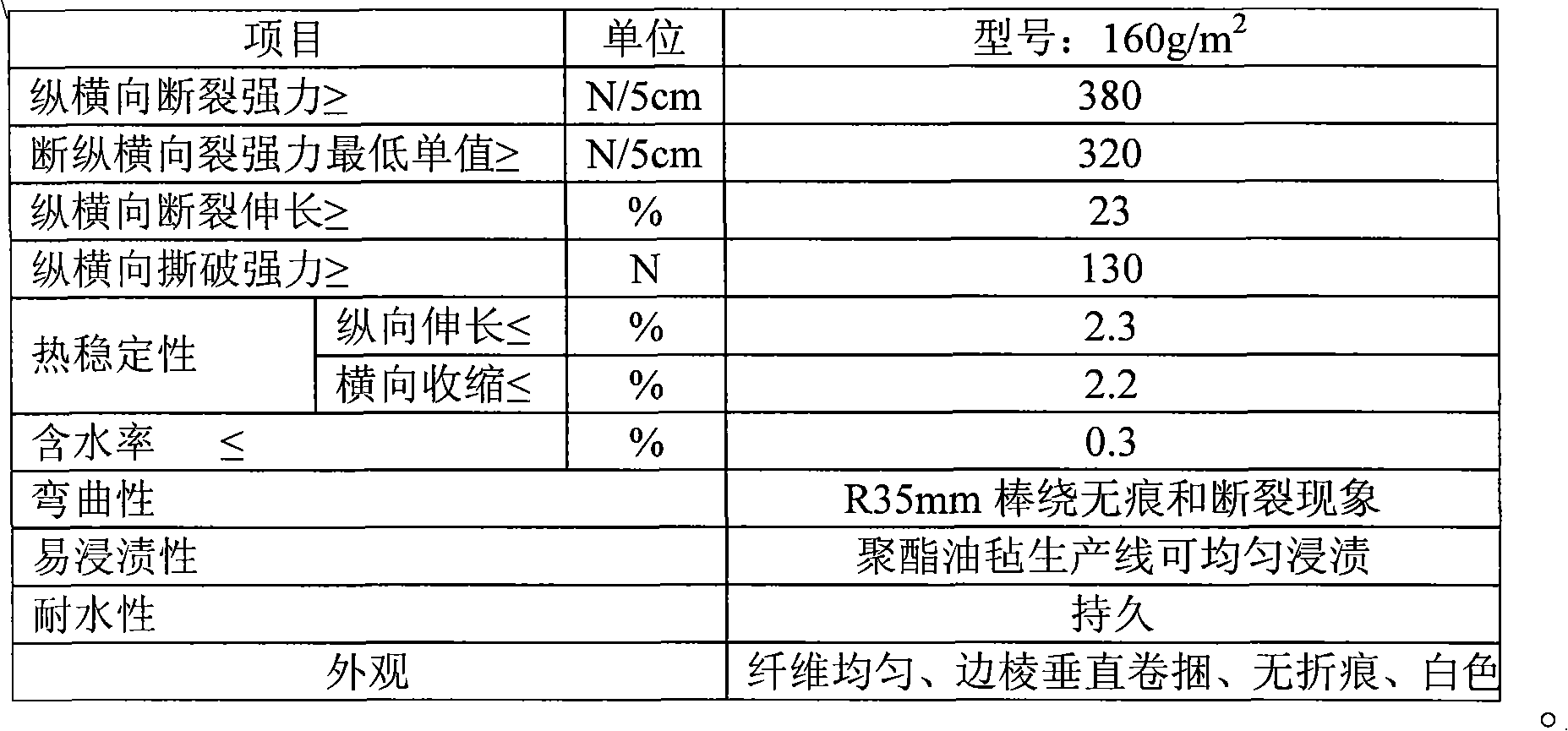

[0032] After testing, its performance indicators meet the requirements in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com