Method for stabilizing foundation based on electro-osmosis technique and bucket foundation negative pressure technique

A cylindrical foundation and foundation reinforcement technology, which is applied in basic structure engineering, soil protection, construction, etc., can solve the problem that the cylindrical foundation is difficult to meet the requirements of bearing capacity and stability, and achieve outstanding effects, low cost, The effect of improving bearing capacity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

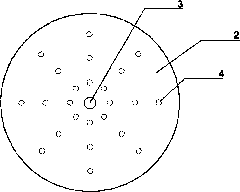

[0019] The implementation environment is beach and sea conditions. The cylindrical foundation 1 is made of concrete material, with a diameter of 6m and a cylinder height of 9m. The diameter of the hole 3 reserved on the top cover plate 2 of the cylinder is 90mm, and a drainage pipe 4 is vertically fixed under the top cover plate 2. , the drain pipe 4 is a plastic pipe; the drain pipe 4 is radially and evenly distributed along the plane of the top cover plate, and the spacing is 1m; the diameter of the drain pipe 4 is 50mm, the length of the drain pipe 4 is from 3m to 9m, and the length of the drain pipe 4 The distribution increases from the reserved hole 3 to the cylinder wall; the wall of the drain pipe 4 is provided with sieve holes 5, the diameter of which is 5mm, and the sieve holes 5 are evenly distributed with a distance of 20mm. An electroosmosis anode 7 is arranged on the inner wall of the cylindrical foundation 1, and an electroosmosis cathode 8 is arranged on the drai...

Embodiment 2

[0021] The implementation environment is 30 meters deep sea water condition, the cylindrical foundation 1 is made of concrete material, the diameter is 12m, the height of the cylinder is 10m, the diameter of the reserved hole 3 on the top cover plate 2 is 100mm, and drainage is fixed vertically under the top cover plate 2 The pipe 4 and the drain pipe 4 are round steel pipes; the drain pipes 4 are evenly distributed radially along the plane of the top cover plate with a distance of 2m; the diameter of the drain pipe 4 is 80mm, the length of the drain pipe 4 is from 4m to 10m, and the drain pipe 4 The length of the drain pipe increases from the reserved hole 3 to the direction of the cylinder wall. The wall of the drain pipe 4 is provided with sieve holes 5. The diameter of the sieve holes 3 is 6mm, evenly distributed, and the distance is 50mm. An electroosmosis anode 7 is arranged on the inner wall of the cylindrical foundation 1, and the drain pipe 4 is an electroosmosis catho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com