DC motor and carbon brush thereof

A technology of DC motors and carbon brushes, applied in circuits, current collectors, electrical components, etc., can solve problems such as complex processes, and achieve the effects of improving fluctuations, increasing differences, and reducing contact points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

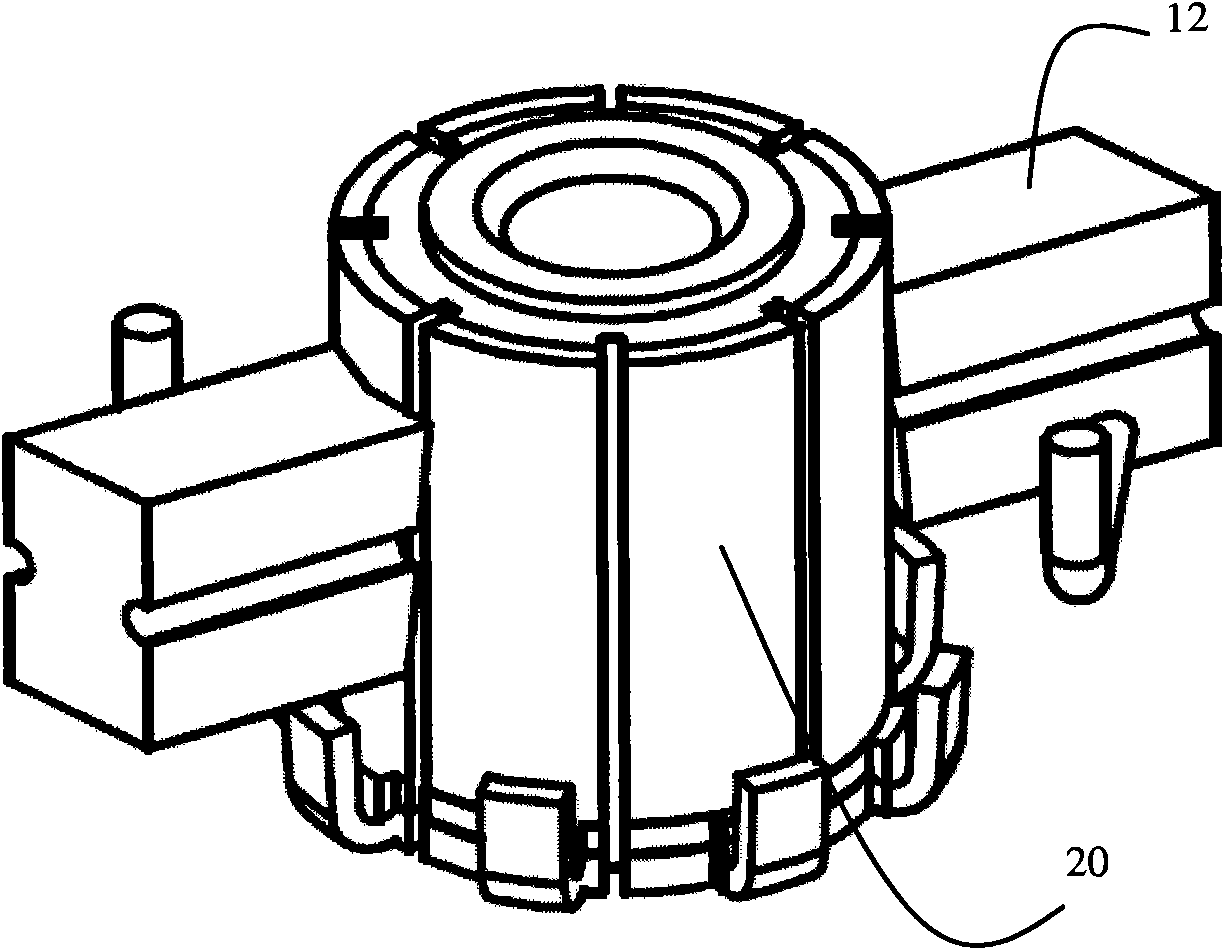

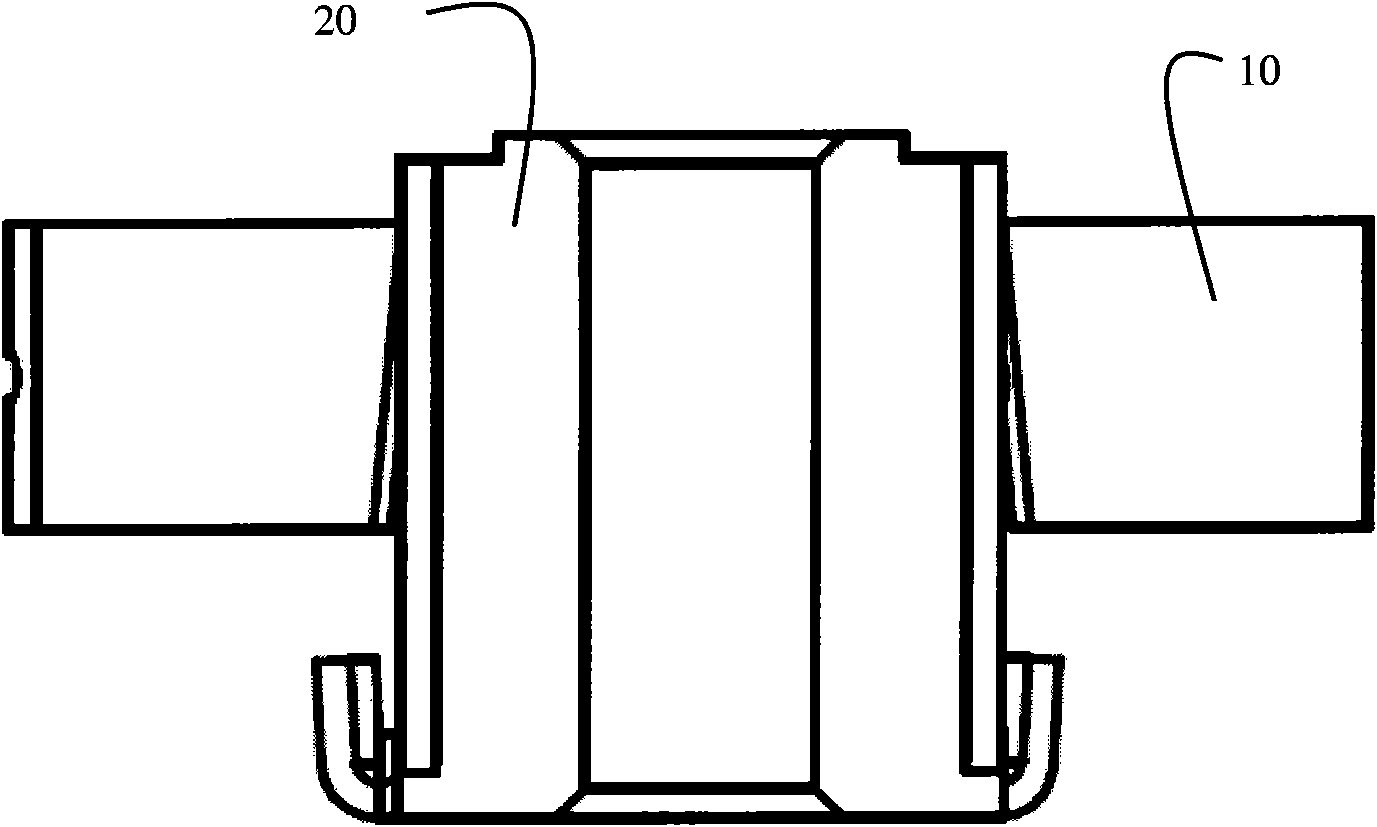

[0026] The present invention will be described below in conjunction with the accompanying drawings.

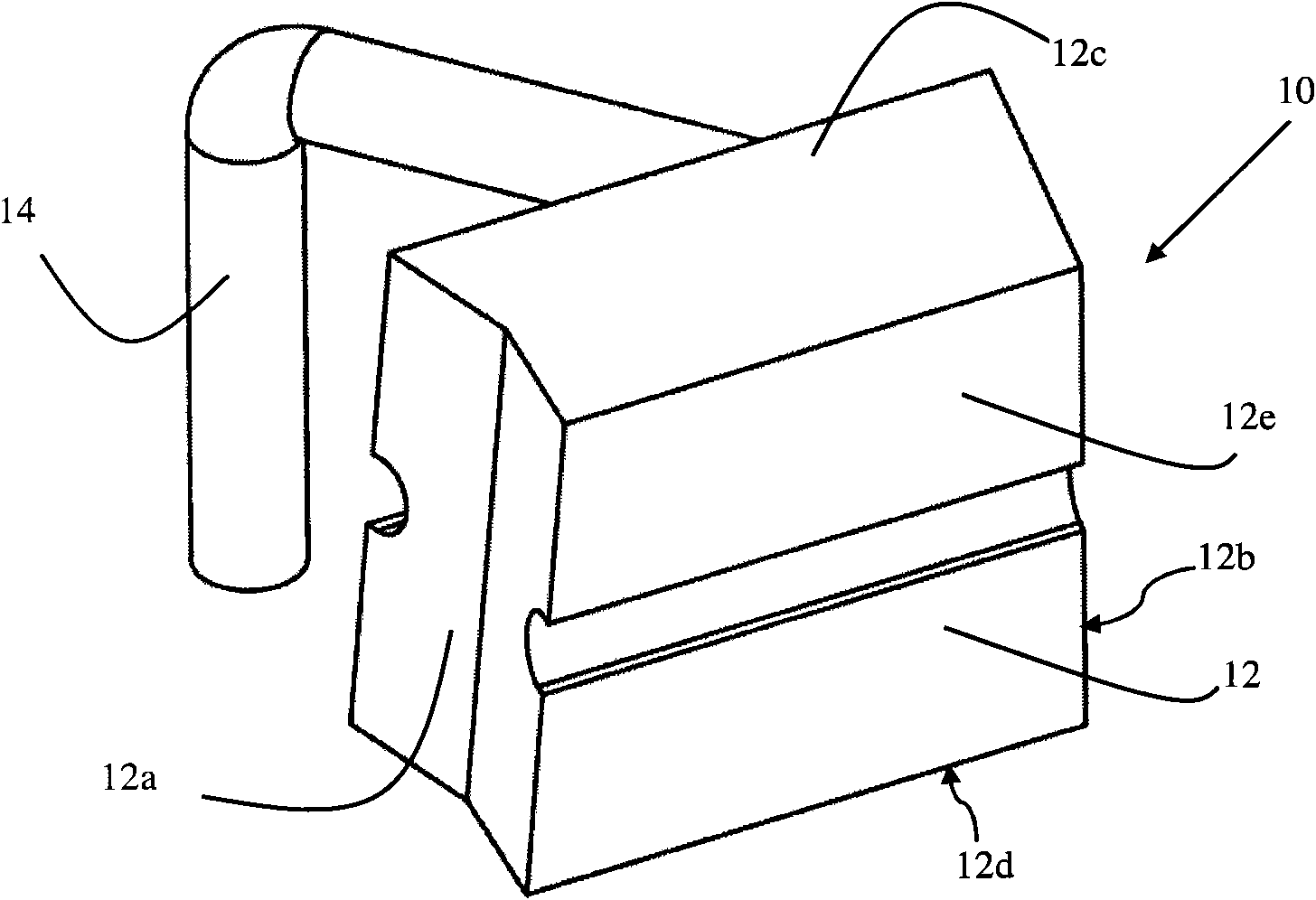

[0027] figure 1 Shown is a three-dimensional schematic diagram of a carbon brush according to an embodiment of the present invention.

[0028] see figure 1 A. A carbon brush 10 according to an embodiment of the present invention includes a carbon brush body 12 and a brush 14 fixed to the body 12 . The carbon brush body 12 is substantially hexahedral, including a front face 12a, a rear face 12b, a top face 12c, a bottom face 12d and a pair of side faces 12e. In the present invention, the distance between the front face 12a and the back face 12b of the carbon brush body 12 is defined as the length of the carbon brush body, the distance between the top surface 12c and the bottom surface 12d is the height of the carbon brush body, and the distance between the two sides 12e is the carbon brush body. The width of the body.

[0029] The brush section 14 extends from a side surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com