Drum type vacuum charging machine

A feeder and drum type technology, which is applied in the field of tobacco silk making automation equipment, can solve the problems of influence of feeding accuracy, slow absorption of feed liquid, loss of aroma, etc., so as to avoid deviation of feeding accuracy, improve uniformity and avoid waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

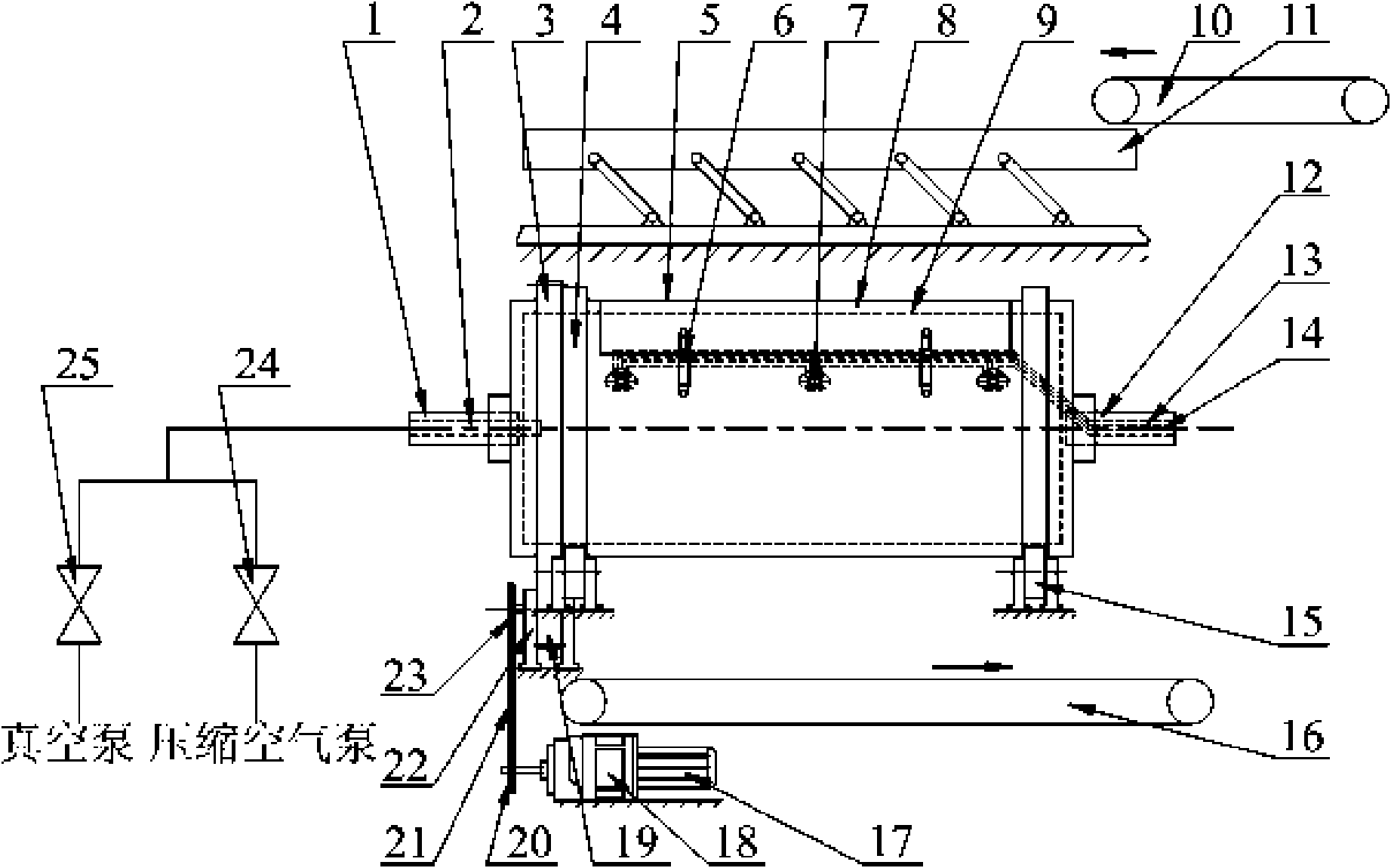

[0028] Example: such as figure 1 As shown, the present invention comprises a feeding drum, a feeding device, a feeding device, a discharge conveying device, a vacuum device, a compressed air device, a motor 17 and a transmission device, and a feeding device conveying pipeline is installed at one end of the feeding drum, and a vacuum is installed at the other end. The pipeline 2, the vacuum device and the compressed air device are respectively connected in parallel to the vacuum pipeline 2 through a pneumatic valve, and the two ends of the feeding roller are respectively provided with supporting raceways 4, and the feeding roller rotates together with the supporting raceway 4, and the feeding roller passes through the transmission device and the motor 17 The connection, feeding device and discharging conveying device are respectively placed above and below the feeding drum.

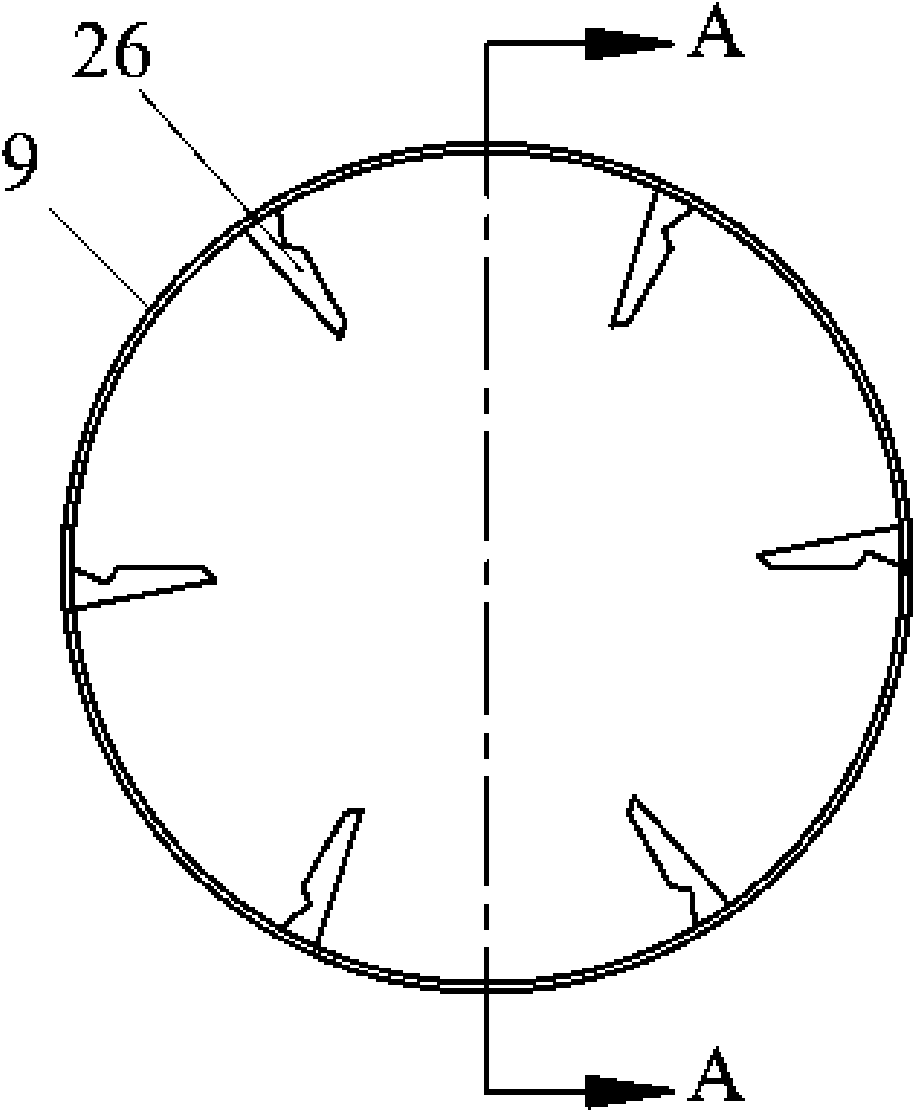

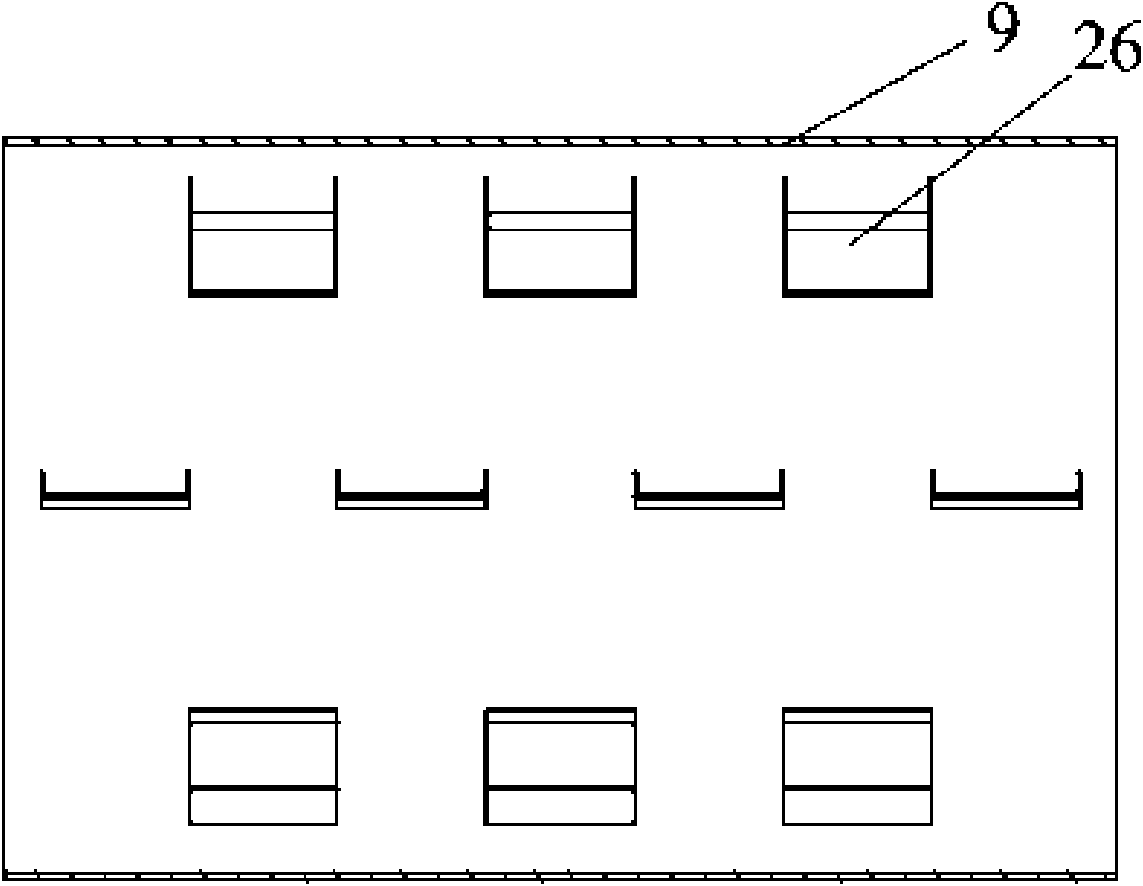

[0029] Such as figure 1 As shown, the feeding drum described in this example is a double-layer cylindr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com